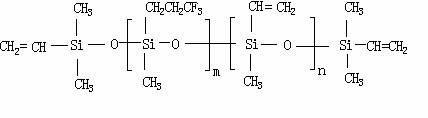

Fluorine silicon mixed making rubber and preparation method thereof

A technology of mixing rubber and fluorosilicone raw rubber, which is applied in the field of fluorosilicone mixing rubber and its preparation, and achieves the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Put 100 parts by weight of fluorosilicone raw rubber into the open mill, adjust the roller distance until there is a small amount of glue between the two rollers, and then add 4 parts by weight of methyl vinyl silicone rubber, and the specific surface area of 45 parts by weight is 200m 2 / g of fumed silica treated with hexamethyldisilazane, 8 parts by weight of hydroxyfluorosilicone oil, 5 parts by weight of heat stabilizer iron oxide red, mixing for 20 to 30 minutes, and then adjusting the roll distance to 0.4 After ~0.6 mm thin pass 10 times, 1 part by weight of 2.5-dimethyl-2.5 bis(tert-butylperoxy)hexane was added. The roller temperature is controlled at 50±5°C, the mixing time is 20-30 minutes, and the thickness is adjusted to be suitable for sheet production. Carry out one-stage vulcanization at 170°C×10min in the flat vulcanizer, and two-stage vulcanization at 200°C×4h, and test the samples.

Embodiment 2

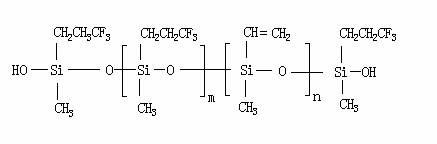

[0052] ① Take 2000g of raw rubber A and raw rubber B in a ratio of 4:6, 40g of methyl vinyl silicone rubber, and an appropriate amount of release agent;

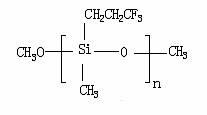

[0053] ②White carbon black 900g, "structural" control agent hydroxyfluorosilicone oil 60g, dimethoxy polytrifluoropropyl methylsiloxane 30g, "concentrated crosslinking agent" vinyl fluorosilicone oil (1) 60g, once or Add to the kneader in batches, and knead evenly at a temperature of 60°C to form a dough;

[0054] ③Raise the temperature to 130°C, knead heat treatment at -0.08~-0.09Mpa for 1 hour under vacuum, the glue will come out below 100°C, and store for 24 hours; no glue will be glued during kneading heat treatment;

[0055] ④After 7 times of re-refining and thinning, extrude and filter with 150 mesh;

[0056] There is no "structural" phenomenon after the rubber is stored for 12 months;

[0057] ⑤Add 1 part by weight of vulcanizing agent [2.5-dimethyl-2.5 bis(tert-butylperoxy)hexane] and iron oxide red to the prepared...

Embodiment 3

[0059] Repeat the steps described in Example 2, changing the raw rubber to raw rubber A and raw rubber B at a ratio of 2:8 to take a total of 2000 g. Knead into a dough at a temperature of 30°C, raise the temperature to 140°C, vacuumize and knead and heat-treat for 0.5 hours, and keep the rubber for 36 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com