Control system for tunnel stratum loss and grouting simulation in centrifugal field

A technology of formation loss and simulation control, applied in tunnels, mining equipment, earthwork drilling, etc., can solve problems such as unrealistic, poor timeliness, and difficulty in obtaining soil parameters, reducing disturbance, facilitating production, and shortening research time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

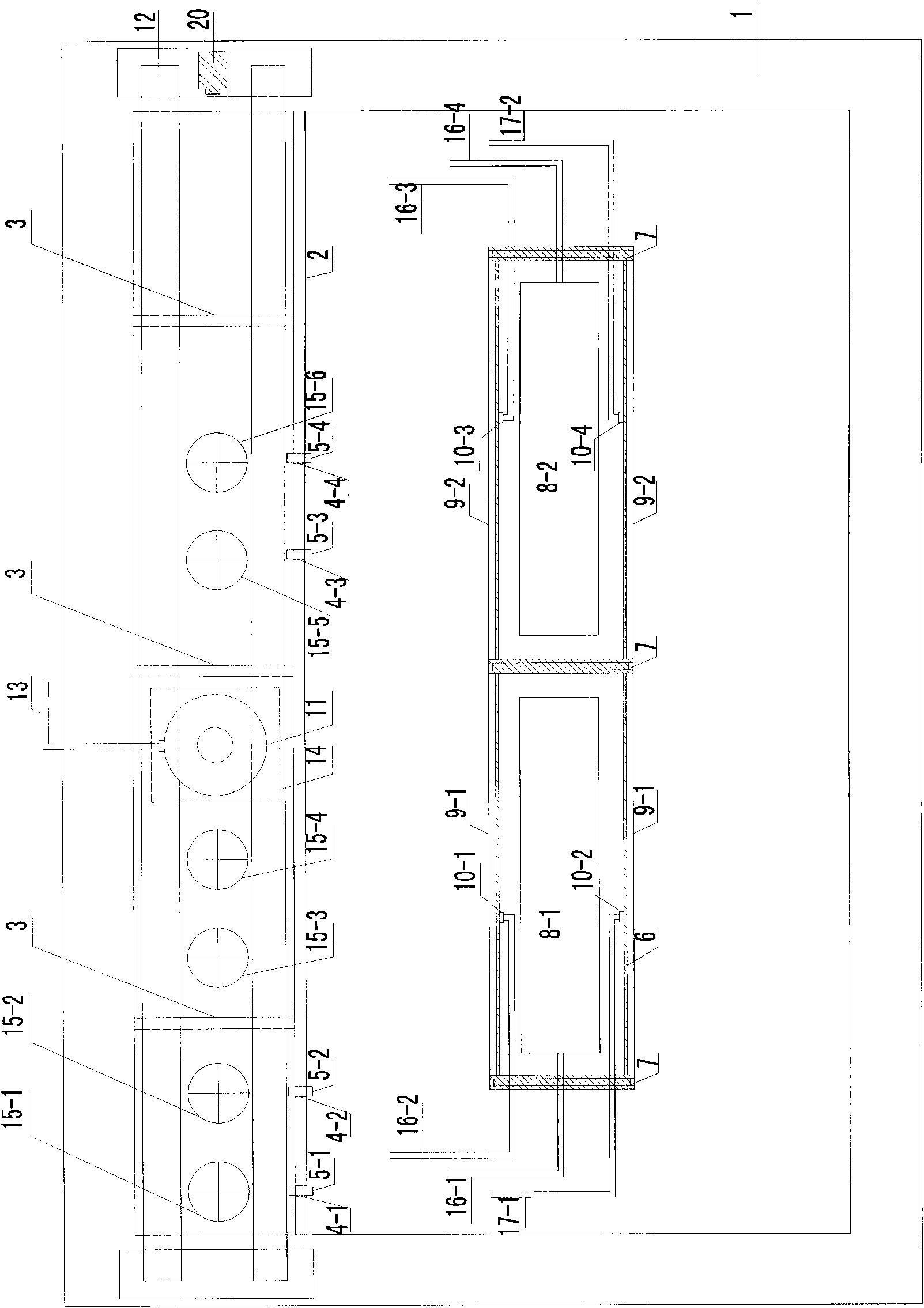

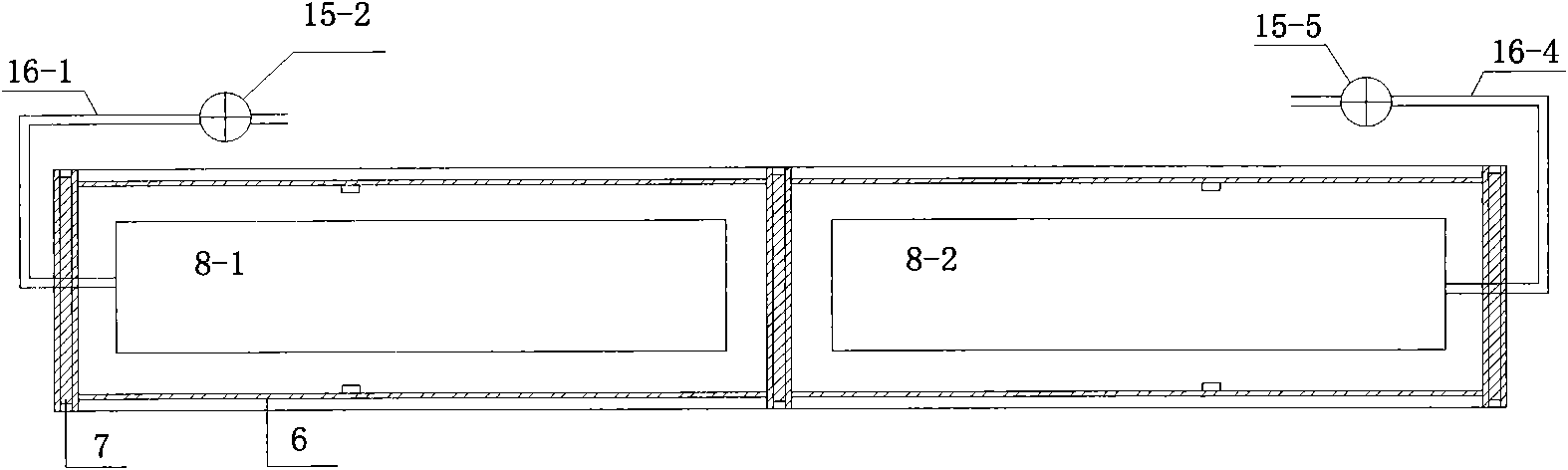

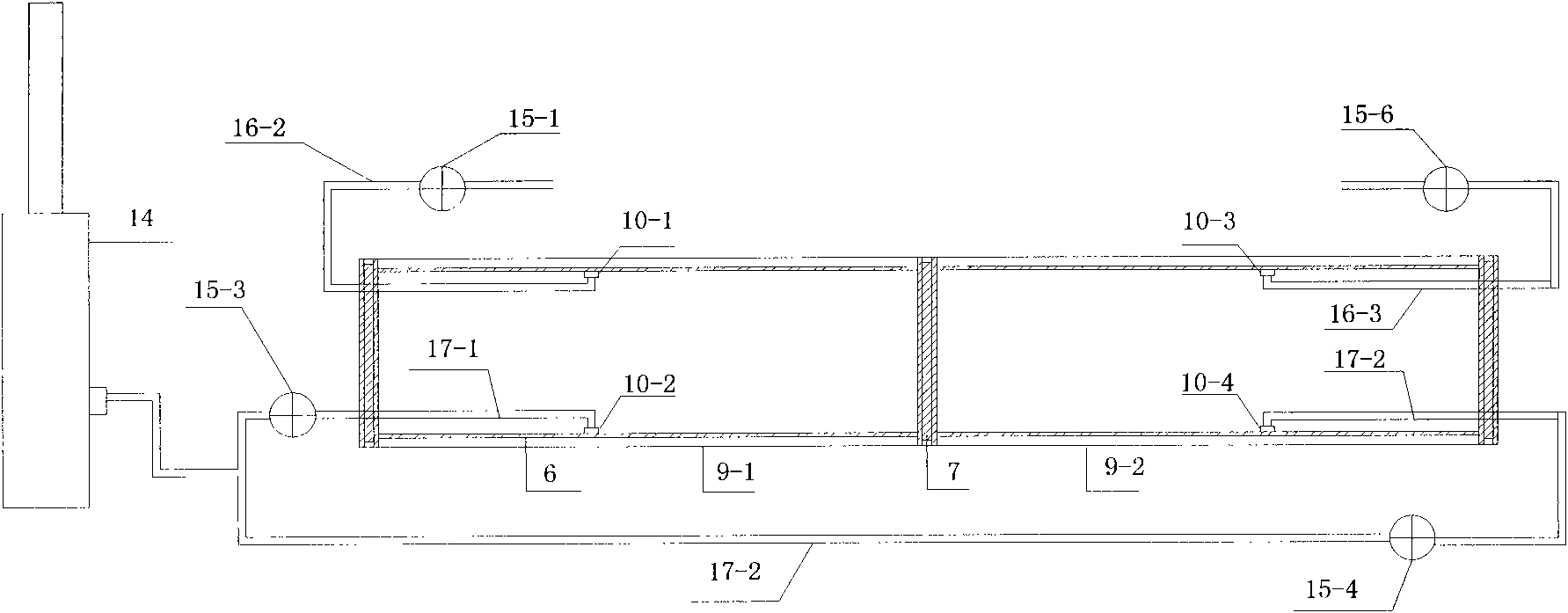

[0030] Such as figure 1 As shown, a tunnel formation loss and grouting simulation control system in a centrifugal field, the system includes a model box 1, a partition 2, a model assembly, an accessory assembly, an operating subsystem, and a centrifuge, and the partition 2 is located at In the model box 1, the model box 1 is divided into two parts, which are the model side and the accessory side. The model component is arranged in the model side, the accessory component is arranged in the accessory side, and the accessory side of the partition plate Three stiffening plates 3 are welded to divide the accessory side into three spaces, the operation subsystem is connected with the accessory assembly, and the model box 1 is installed on the centrifuge.

[0031] Such as Figure 5 , Figure 6 As shown, the partition plate 2 is provided with four threaded holes from left to right, namely the first hole 4-1, the second hole 4-2, and the third hole 4-3. , the fourth hole 4-4, each h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com