Crankcase structure

A crankcase and crankshaft technology, applied in the direction of engine cooling, engine lubrication, gear lubrication/cooling, etc., can solve the problems of oil return lag, friction increase, weight increase, etc., to suppress weight increase and oil pressure Change, apply the appropriate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

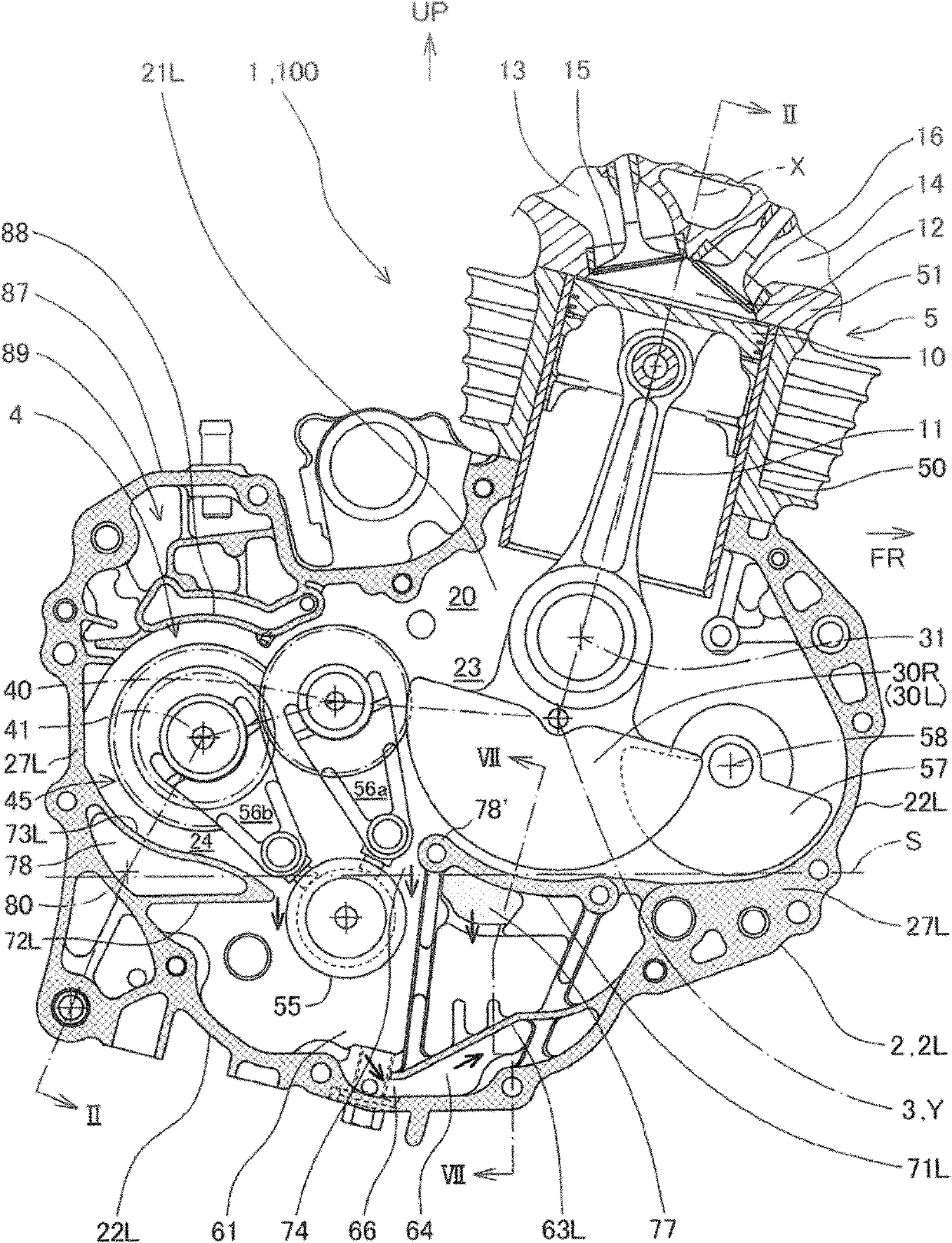

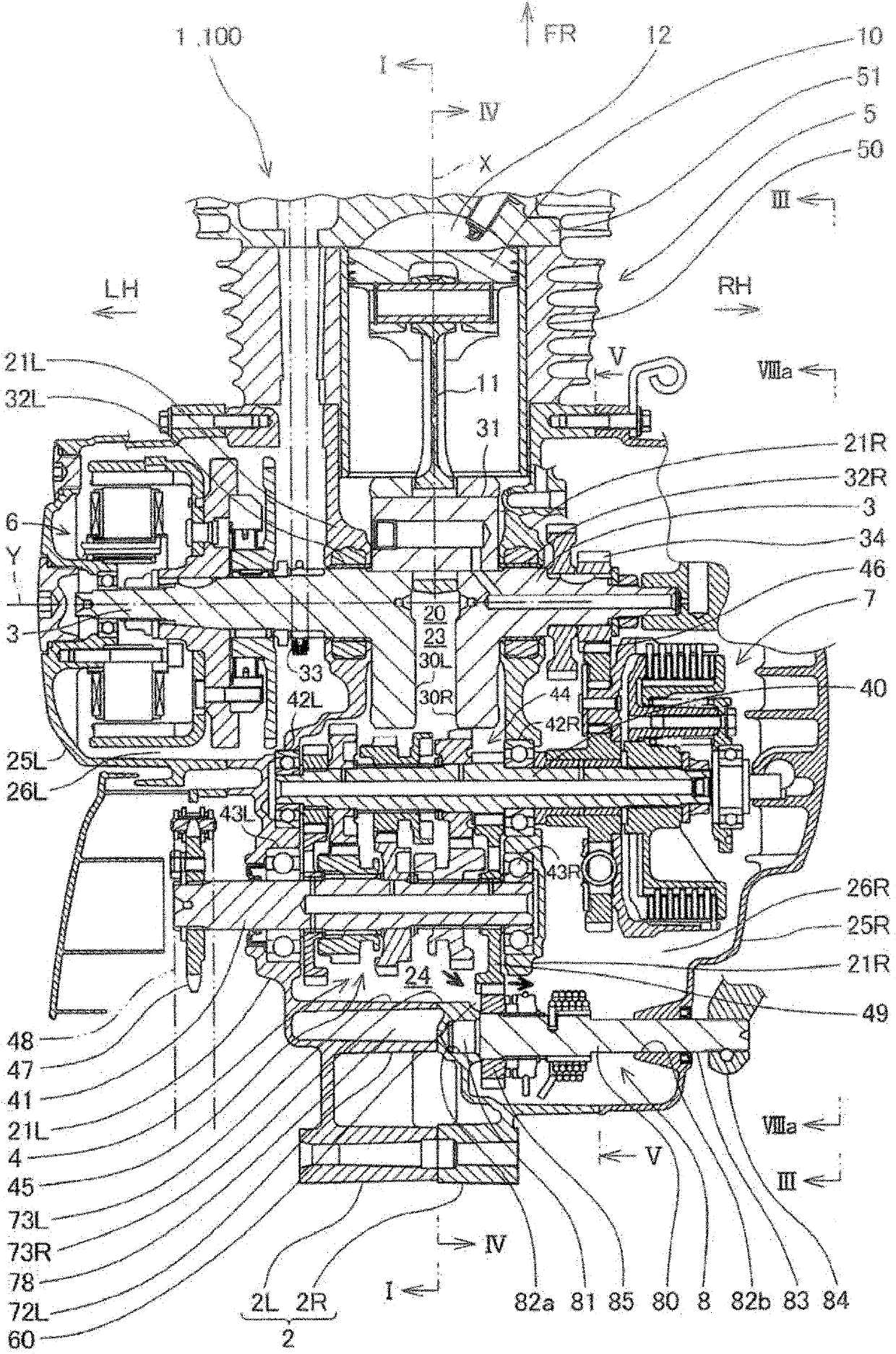

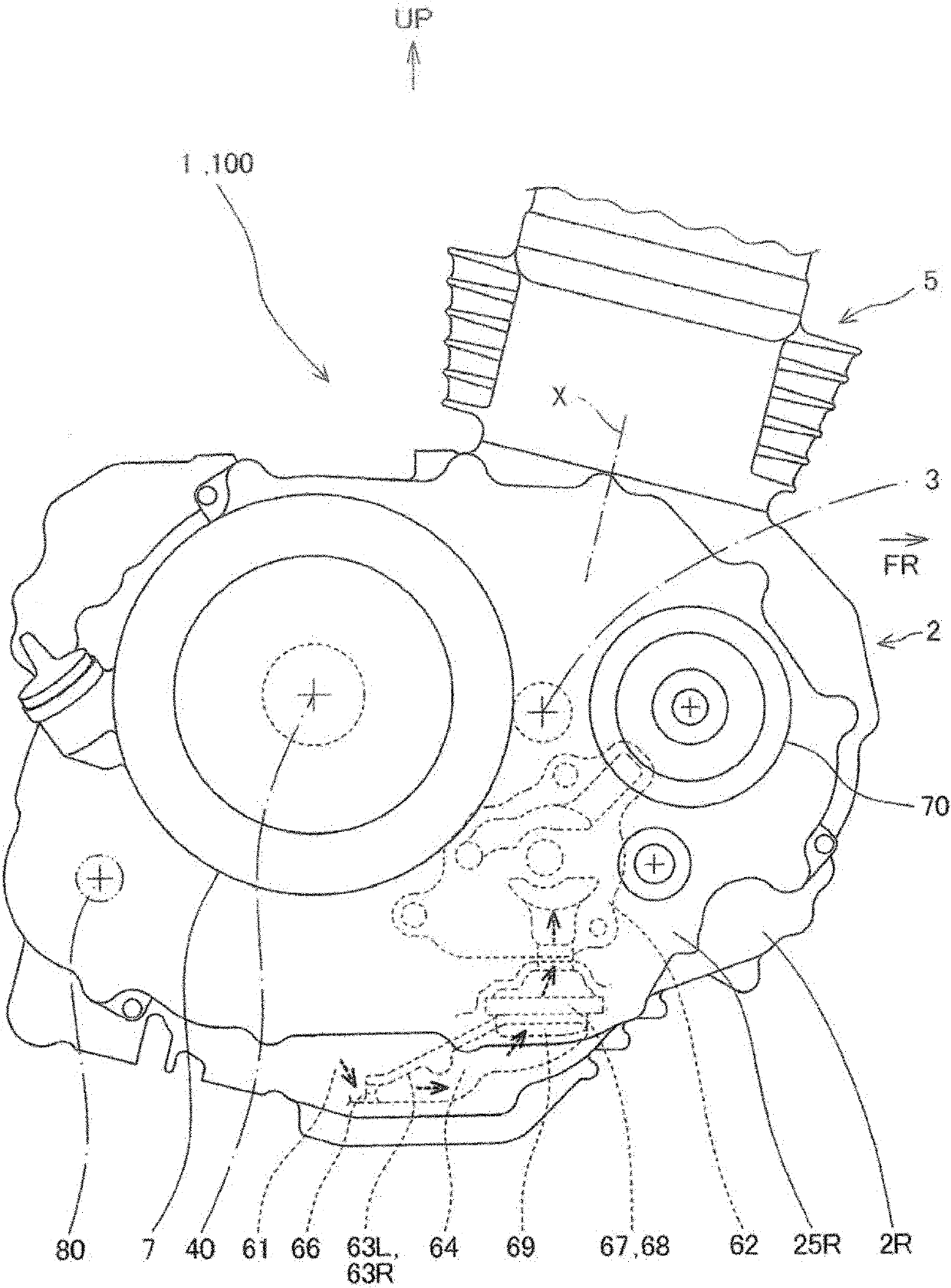

[0050] Below, based on Figure 1 to Figure 11 The crankcase structure of the first embodiment of the present invention will be described.

[0051] In the present specification and claims, directions such as front, rear, left, right, up and down correspond to the direction of the vehicle when the internal combustion engine of the present embodiment is mounted on a vehicle such as a motorcycle. In the figure, arrow FR indicates the front of the vehicle, LH indicates the left side of the vehicle, RH indicates the right side of the vehicle, and UP indicates the upper side of the vehicle.

[0052] In addition, the small arrows attached to the devices and structural parts in each figure schematically indicate the flow direction of lubricating oil.

[0053] The internal combustion engine 1 of the present embodiment is a single-cylinder four-stroke internal combustion engine. In a vehicle not shown, such as a motorcycle, the internal combustion engine 1 is arranged such that the cran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com