Testing device and method for hydrogen constant-volume compression ignition

A test device, hydrogen technology, applied in the direction of internal combustion engine testing, etc., can solve the problems of constant volume incendiary bomb heating, diaphragm fire resistance, etc., achieve high heating efficiency, rapid heating, and improve fire resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

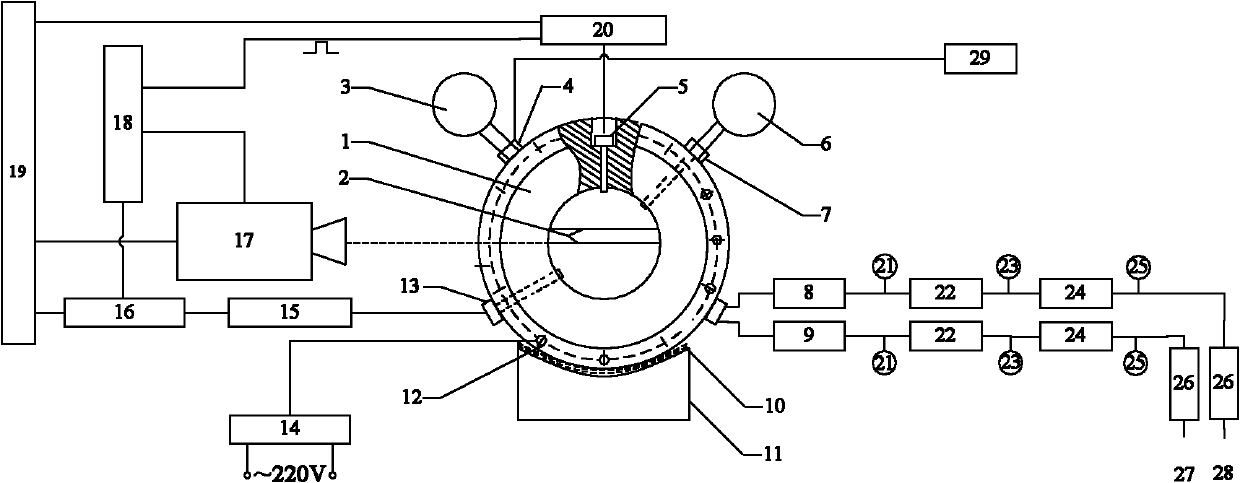

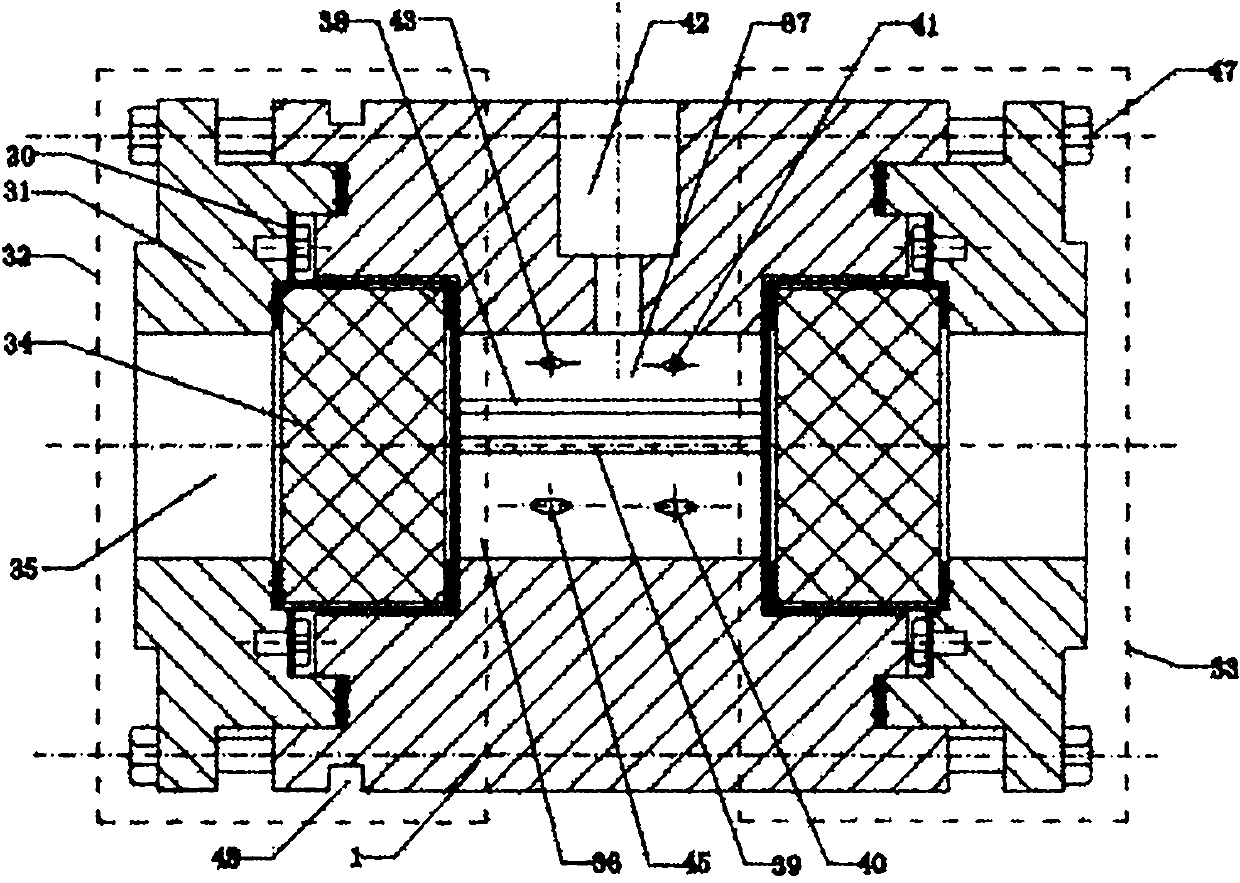

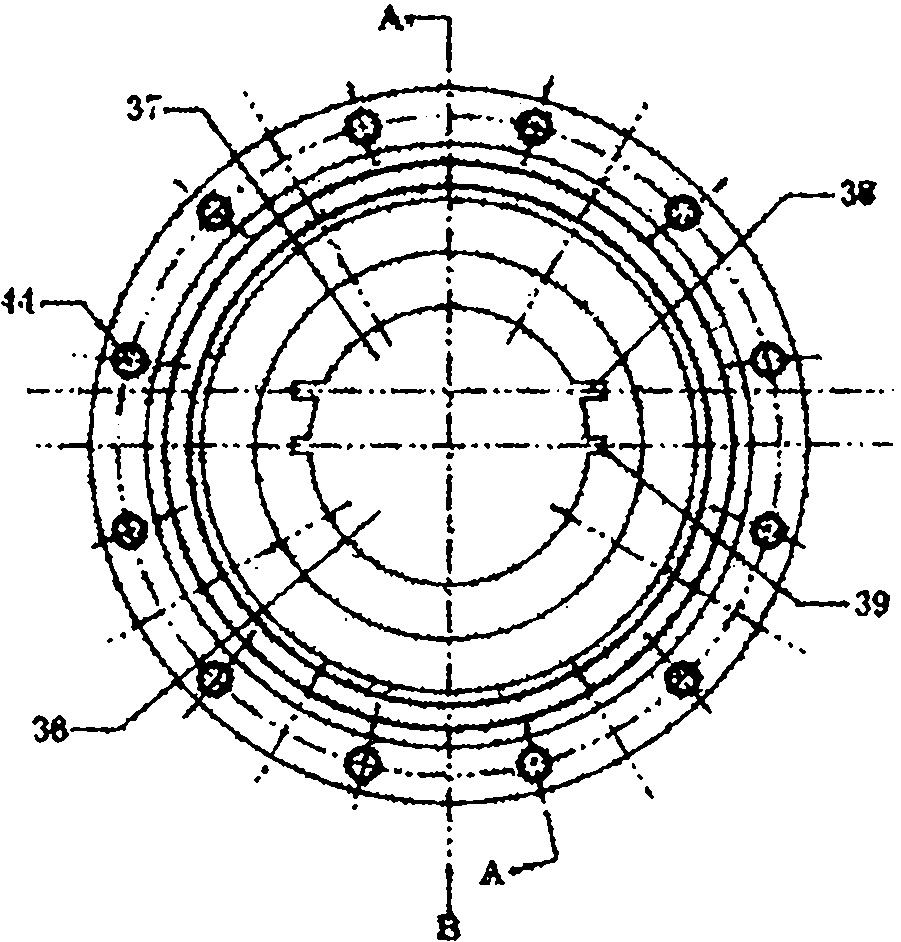

[0074] In order to better illustrate the purpose and advantages of the present invention, the content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0075] Based on the characteristics of the device of the present invention, there are mainly two implementation modes. First, when adding a grooved plug, use this device to study the hydrogen-oxygen flame propagation process near the wall; second, when adding a diaphragm, use this device to study the compression ignition characteristics of hydrogen, wherein, according to the test It is necessary to select different diaphragms (different numbers of through holes, different diameters of through holes, different fire retardant methods, etc.). Based on the structural characteristics of this device, the device can easily realize the ignition of the center electrode through simple modification (perforating a through hole at the bottom of the container bomb), so a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com