A method and a device for testing an HDMI

A technology of HDMI interface and testing equipment, which is applied in the field of interface testing, can solve problems such as inability to accurately test HDMI socket connection welding or virtual welding, and achieve the effect of simple structure and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

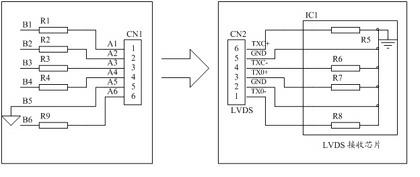

[0022] Such as image 3 The LVDS interface pin open-short test principle is shown, and the LVDS interface test equipment tests whether each pin of the LVDS interface CN2 in the circuit to be tested is soldered or adjacent pins are short-circuited. The LVDS interface testing equipment is connected to the LVDS interface CN2 through the interface CN1, and the LVDS interface CN2 is connected to the LVDS receiving chip IC1 in the circuit to be tested. Among them, TXC+ and TXC- form a pair of differential pairs, TX0+ and TX0- form a pair of differential pairs, resistance R5, resistance R6, resistance R7 and resistance R8 are the internal equivalent resistance of LVDS receiving chip IC1; the interface CN1 in the LVDS interface test equipment A resistor R1, a resistor R2, a resistor R3, a resistor R4 and a resistor R9 are respectively connected in series on pins 1, 2, 3, 4, and 6.

[0023] After the LVDS interface test equipment is connected to the LVDS interface CN2 in the circuit t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com