Thermoplastic resin composition for cleaning molding machine

A technology of thermoplastic resin and molding processing, which is applied in the field of thermoplastic resin composition for cleaning molding processing machines, can solve problems such as insufficient cleaning performance, and achieve the effects of excellent cleaning performance, excellent removal performance, and excellent replacement performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4、 comparative example 1~4

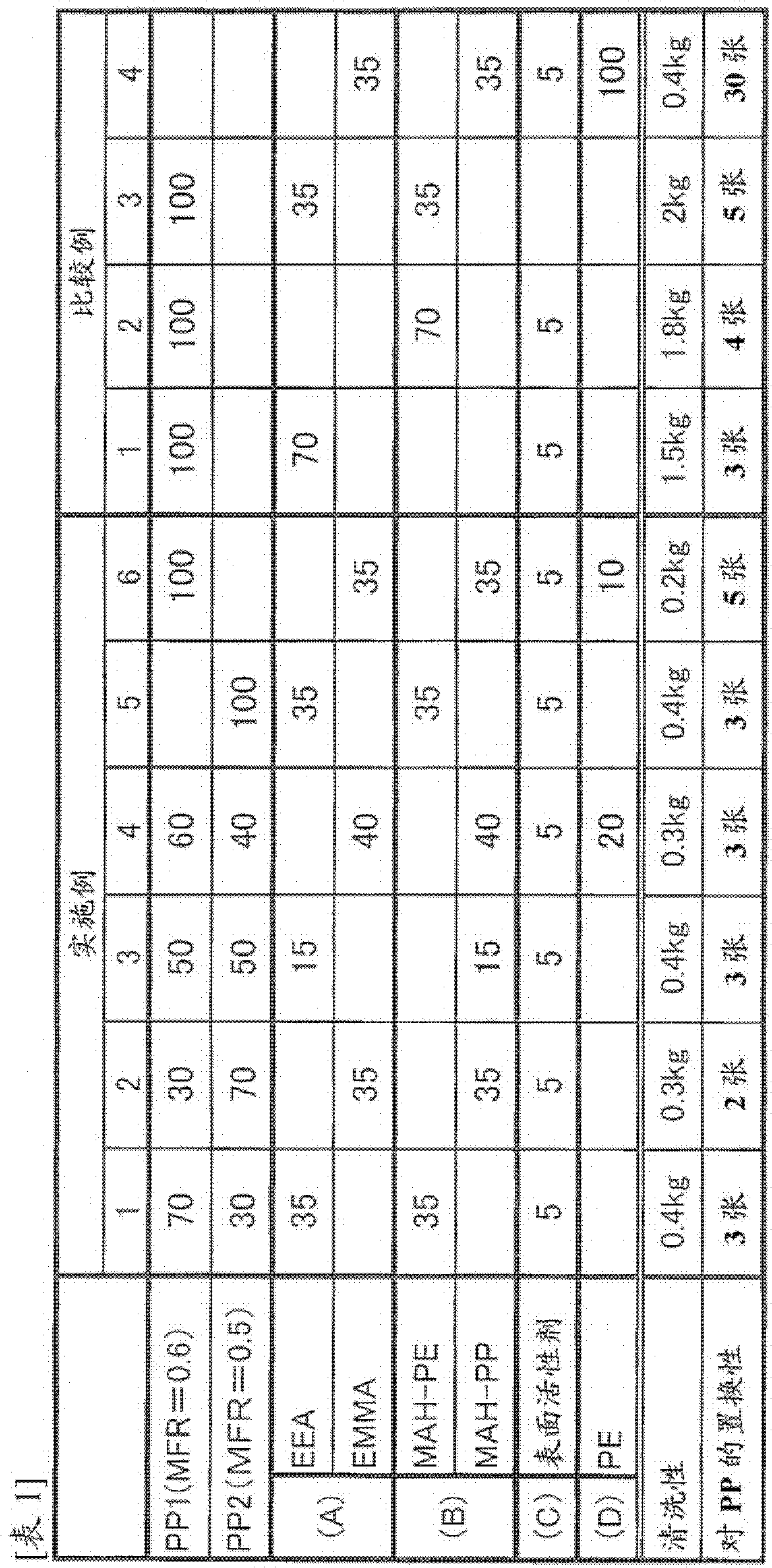

[0037] The components of the composition shown in Table 1 were mixed using a drum mixer, and then melt-kneaded by an extruder to obtain a granular cleaning resin composition. Using the above-mentioned composition, a cleaning test was carried out according to the following method. The results are shown in Table 1.

[0038] (cleaning)

[0039] 1 kg of a blackened product (dry colorant; carbon black concentration 2%) of polypropylene resin (Prime Polypro J-2000GP manufactured by Prime Polymer Co., MFR21), which was previously used as a resin, was poured into an injection molding machine (" Mitsubishi injection molding machine 265 / 100MSII"; barrel temperature 250°C). Then, each cleaning resin composition having the composition in Table 1 was poured, and evaluated by the amount of the composition used until the black color disappeared (confirmed by visual inspection).

[0040] (Substitution for polypropylene resin)

[0041] After cleaning, 1 kg of polypropylene resin (Prime Pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com