Microlithographic projection exposure apparatus

A technology of microlithography and equipment, applied in the field of lighting systems and projection objective lenses, which can solve the problems of inability to guarantee heat dissipation and damage to components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

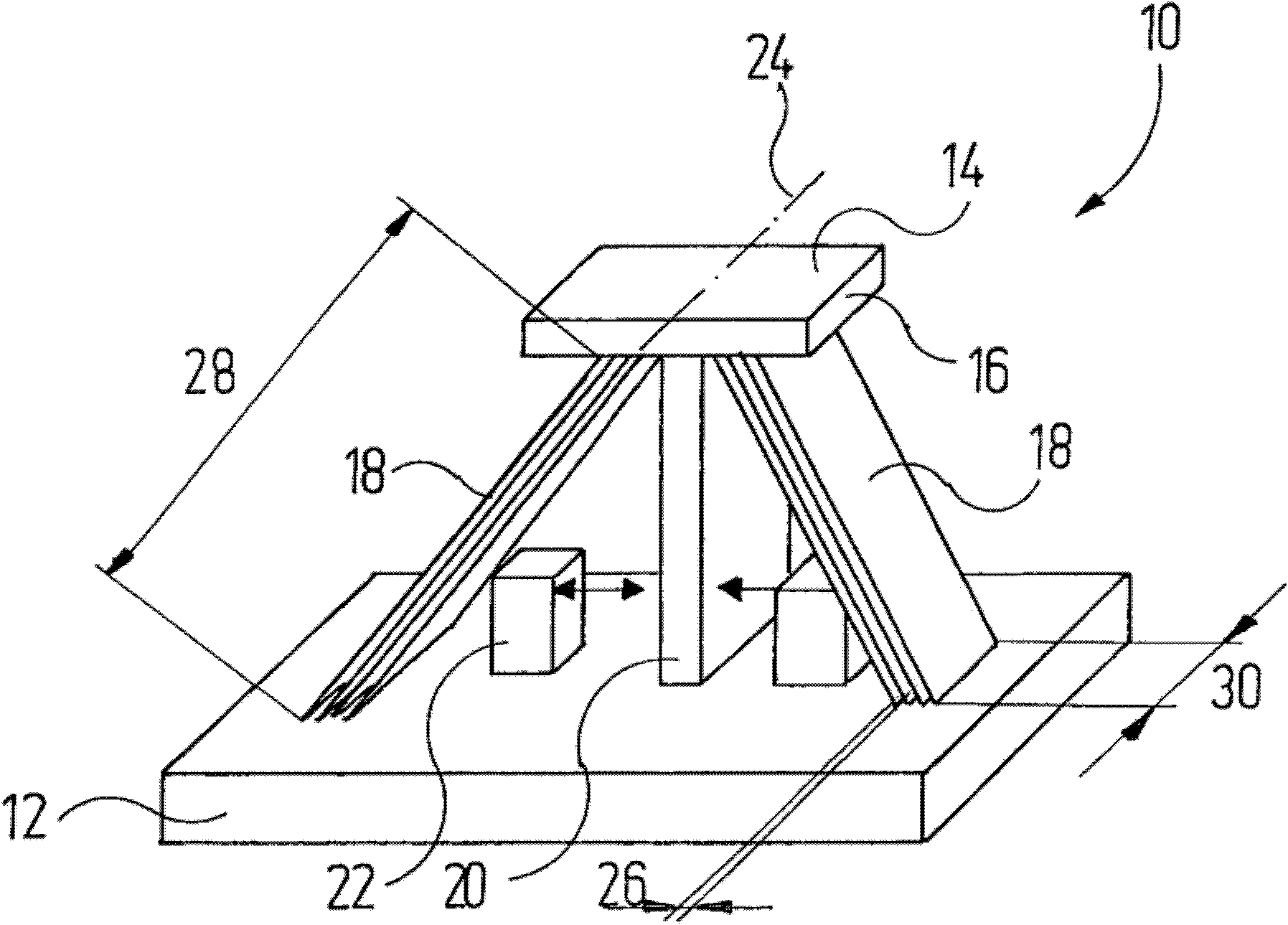

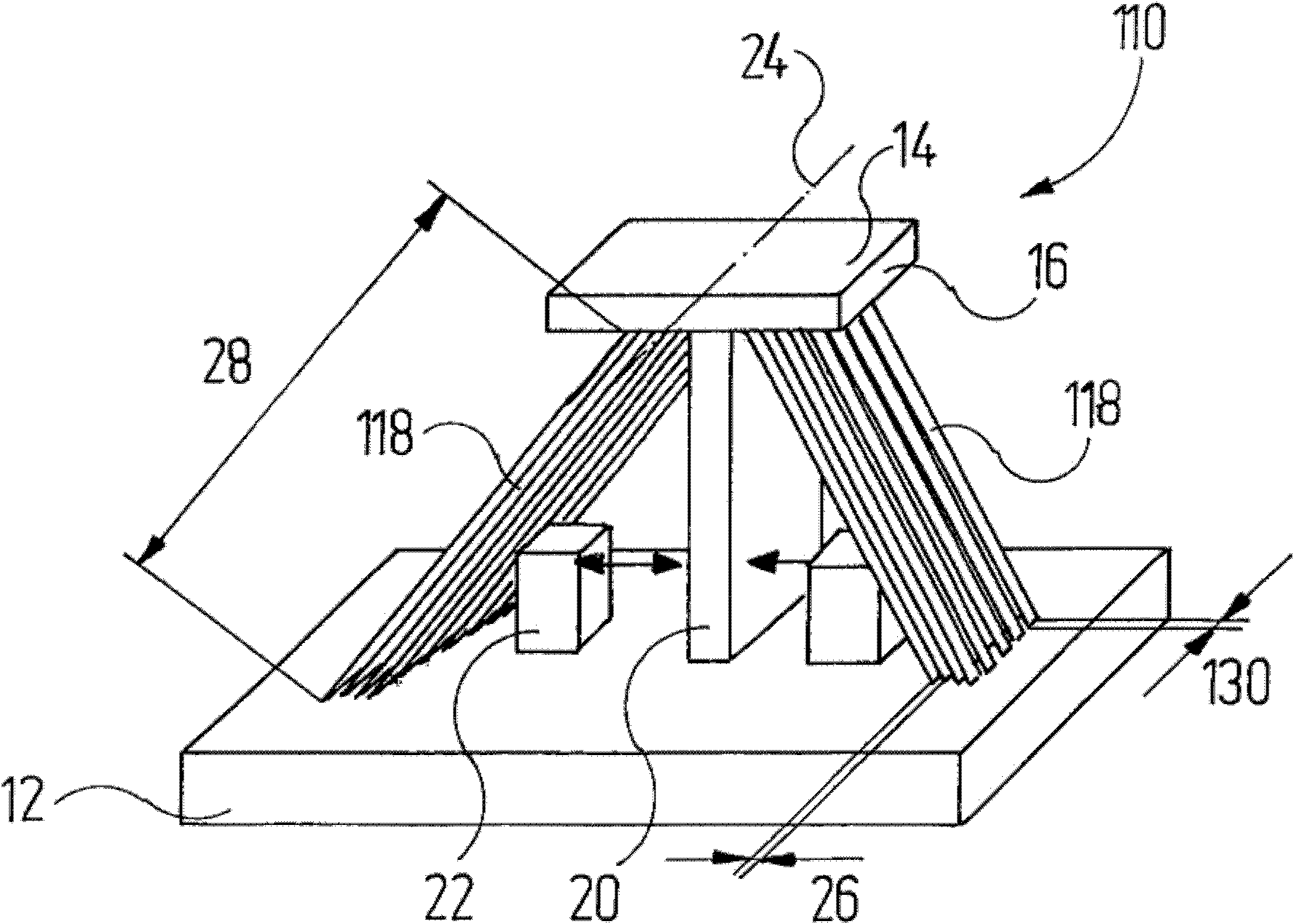

[0085] figure 1 A perspective view showing a detail of a mirror unit 10 included in an illumination system of a projection exposure apparatus for microlithography. The details shown reveal a base plate 12, a mirror unit with a mirror 14, and two sets of leaf springs 18, the mirror 14 being held on a T-shaped support 16, and two sets of leaf springs 18 connected to the support 16 and the base plate 12 and is constructed of a material with high thermal conductivity such as steel, silicon, silicon carbide, copper, silver or gold. The leaf spring 18 together with the support body 16 forms a solid joint for the mirror 14 .

[0086] The mirror unit also has two magnetic coils 22 arranged between the leaf spring 18 and the longer branch of the support body 16 . Of course, other drives can also be used instead of magnetic coils. The mirror unit includes figure 1 A plurality of mirror units are shown, for example hundreds or even thousands, arranged on a common base plate 12 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com