Heteroatom-doped hard carbon material and preparation method thereof

A heteroatom and hard carbon technology, which is applied in the field of heteroatom-doped hard carbon materials and preparation, can solve the problems of high preparation cost of heteroatom-doped hard carbon materials, expensive titanium raw materials, poor rate performance, etc. Diffusion ability, low manufacturing cost, and the effect of improving conduction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A heteroatom doped hard carbon material comprising the following raw materials: a gram of urea, 2.5A-3.5A gram of bacterial cellulose, 1.1A-1.6A gram of amphidinol, 0.1-0.2A ml mass fraction It is 60-80% ethylenediamine solution.

Embodiment 2

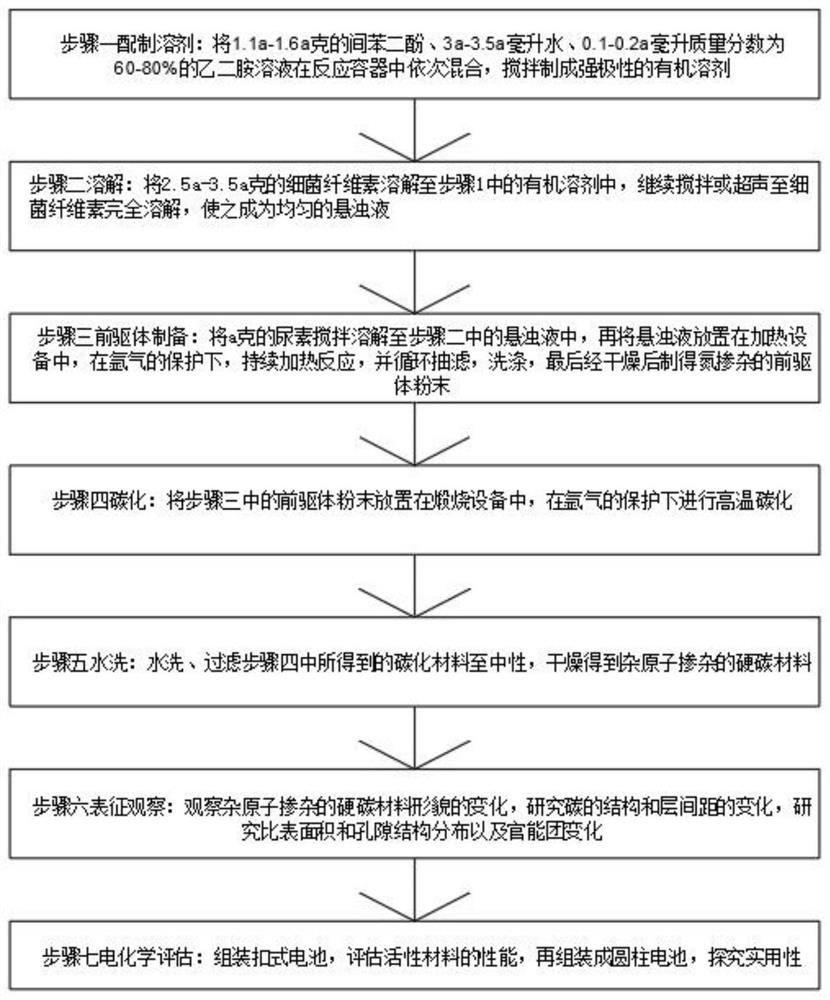

[0034] Refer figure 1 , A method for preparing a heteroatom doped hard carbon material, including the following steps:

[0035] Step, a solvent: 1.1A-1.6A grams of the amphotyldiphenol, 3a-3.5a millis water, 0.1-0.2a milliliters of mass fraction of 60-80% is mixed in the reaction vessel, stir Made of a strong organic solvent;

[0036] Step Dissolution: Dissolve 2.5A-3.5A grams of bacterial cellulose to the organic solvent in the step 1, continued to stir or ultrasonically to the bacterial cellulose completely dissolve, so that it is a uniform suspension, and the stirring time is 0.5 H-0.7H.

[0037] Step three precursor: A gram of urea is stirred into the suspension in step II, and then place the suspension in the heating apparatus, under the protection of argon, continue to heat the reaction, and circulate filtration, Washing, finally prepared a precursor powder after drying;

[0038] Among them, an organic precursor was used to infiltrate the organic precursor with a phosphoric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com