Method for improving winter resistance of turf by adopting household garbage compost offscourings

A technology for composting dregs and municipal solid waste is applied in the field of urban lawn plants that are resistant to severe cold, and municipal solid waste composting dregs to improve the cold resistance and overwintering properties of turf, and can solve the problems of inability to produce, idle time, and resource occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] (1) The compost comes from Tianjin Xiaodian Garbage Compost Treatment Plant, and it is dried to constant weight after coarse screening. Weigh 400g of the dried compost after coarse sieve, put it into a large funnel, measure 400ml tap water and filter, and collect the filtrate. Repeatedly measure twice 400ml of tap water to continue to filter the compost, and collect the filtrate of each time. Mix the filtrate collected three times and store in the refrigerator. Put the compost dregs after three filtrations into an oven at 105°C and bake to constant weight.

[0084] (2) Take ryegrass seeds with full and uniform grains, and sown them in a petri dish with two layers of filter paper and 50g of compost slag after treatment, 1g per dish, and place the seeded petri dish in the laboratory For germination, water once a day in the morning and evening. Change the position of each petri dish frequently to ensure consistent light. During the cultivation period, the average temperat...

Embodiment 2

[0088] The compost comes from Tianjin Xiaodian Garbage Compost Treatment Plant, which is dried to constant weight after coarse screening. Weigh 400g of the dried compost after coarse sieve, put it into a large funnel, measure 400ml tap water and filter, and collect the filtrate. Repeatedly measure twice 400ml of tap water to continue to filter the compost, and collect the filtrate of each time. Mix the filtrate collected three times and store in the refrigerator. Put the compost dregs after three filtrations into an oven at 105°C and bake to constant weight. The planting time is November 18, 2008.

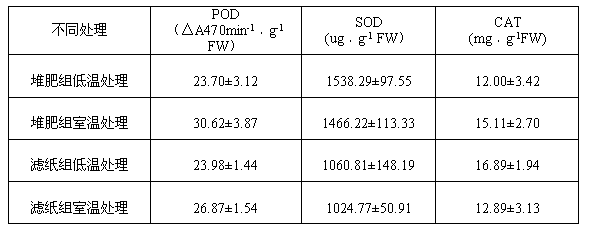

[0089] The seed germination time was November 22, 2008. Starting from the tenth day after the seed germination, 5ml of compost leaching solution was poured into each filter paper culture dish of ryegrass seedlings every day. 40 days after germination, the seeds are moved to a light incubator, the initial set temperature is 12℃, and the temperature is lowered sequentially every day....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com