Polytetrafluoroethylene film longitudinal stretching unit

A technology of polytetrafluoroethylene and longitudinal stretching, which is applied in the direction of thin material processing, winding strips, flat products, etc., can solve the problems of low production efficiency and yield, uneven film thickness, poor quality, etc. Uniform, high air permeability, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

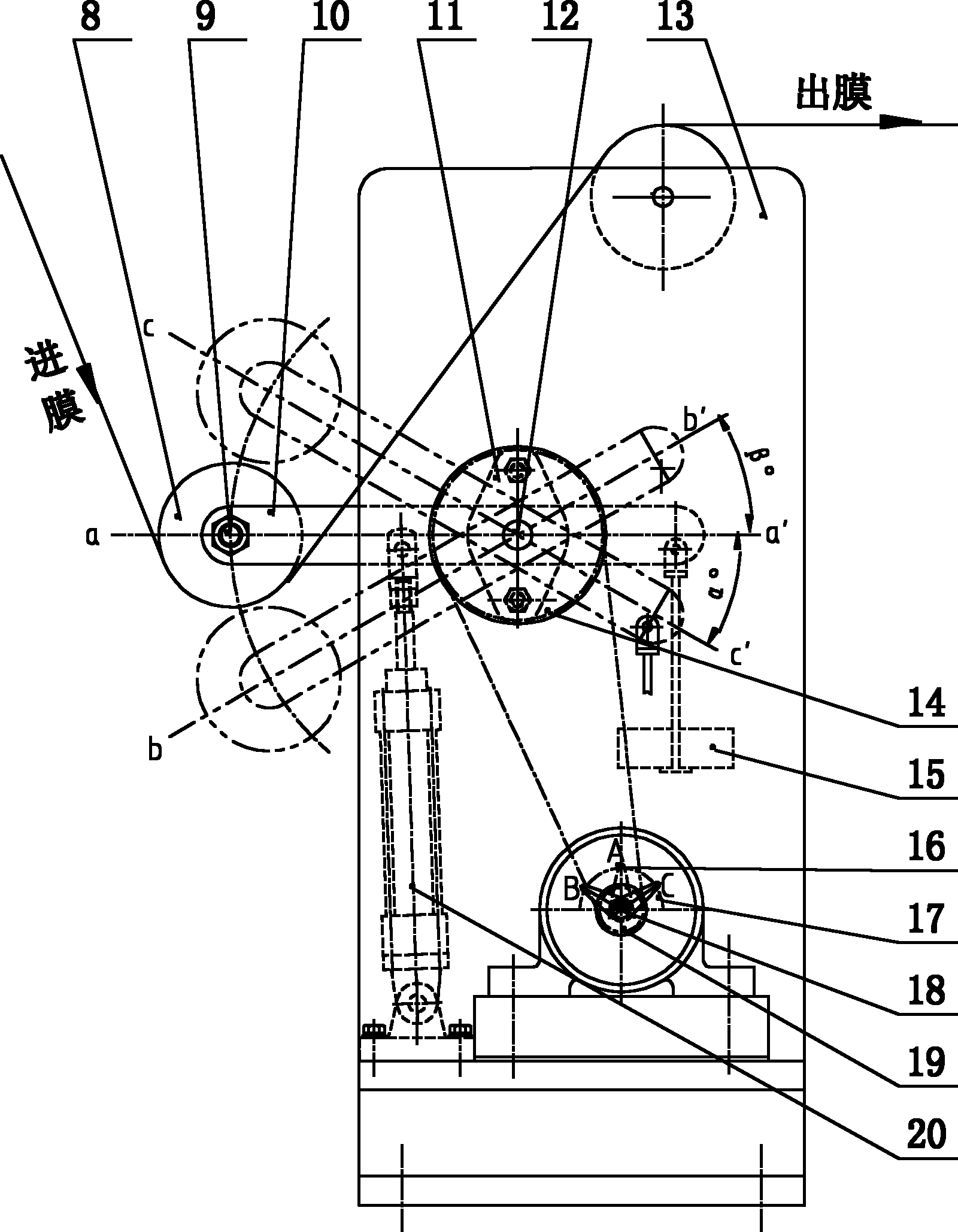

[0020] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings, but it is not intended to limit the content of the present invention.

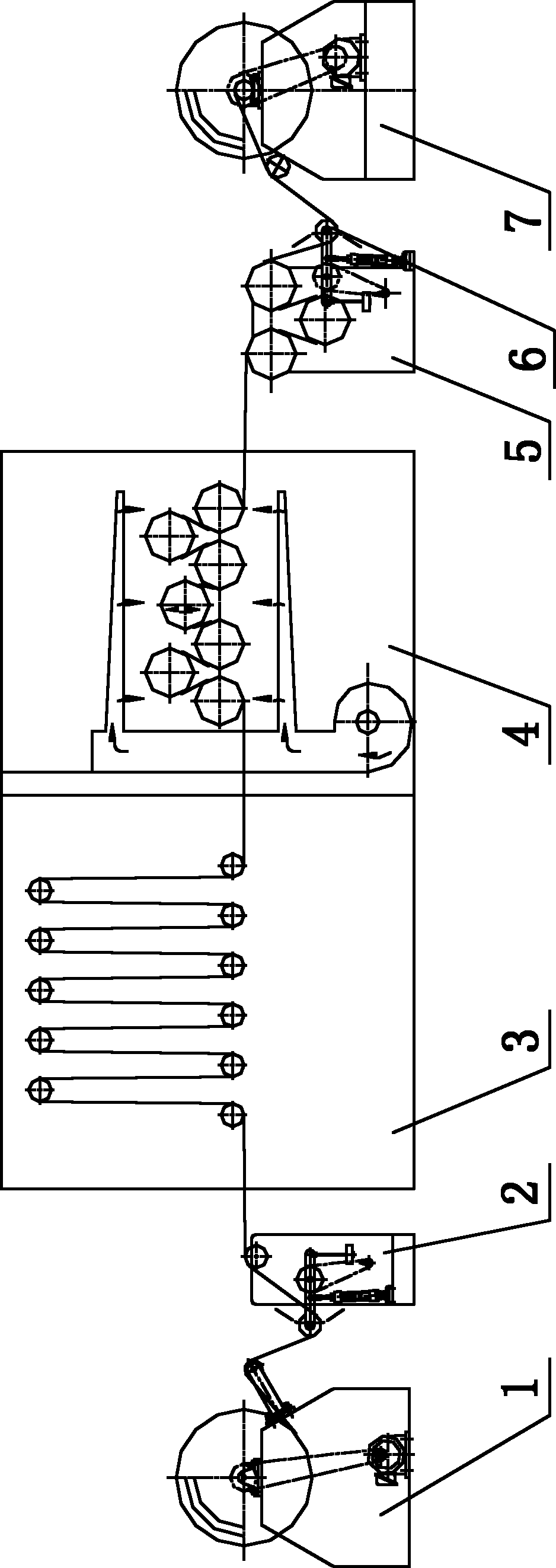

[0021] Such as figure 2 As shown, the polytetrafluoroethylene film longitudinal stretching unit of the present invention includes an unwinder 1, a front tension frame (unwinding tension monitoring device) 2, a multi-roll deoiling furnace 3, a multi-point stretching furnace 4, and a tractor 5 , Rear tension frame (winding tension monitoring device) 6, winding machine 7 and control cabinet.

[0022] The unwinding machine 1 adopts the central active unwinding mode, the unwinding shaft is driven by the unwinding motor after deceleration, and the unwinding motor is controlled by the unwinding frequency converter.

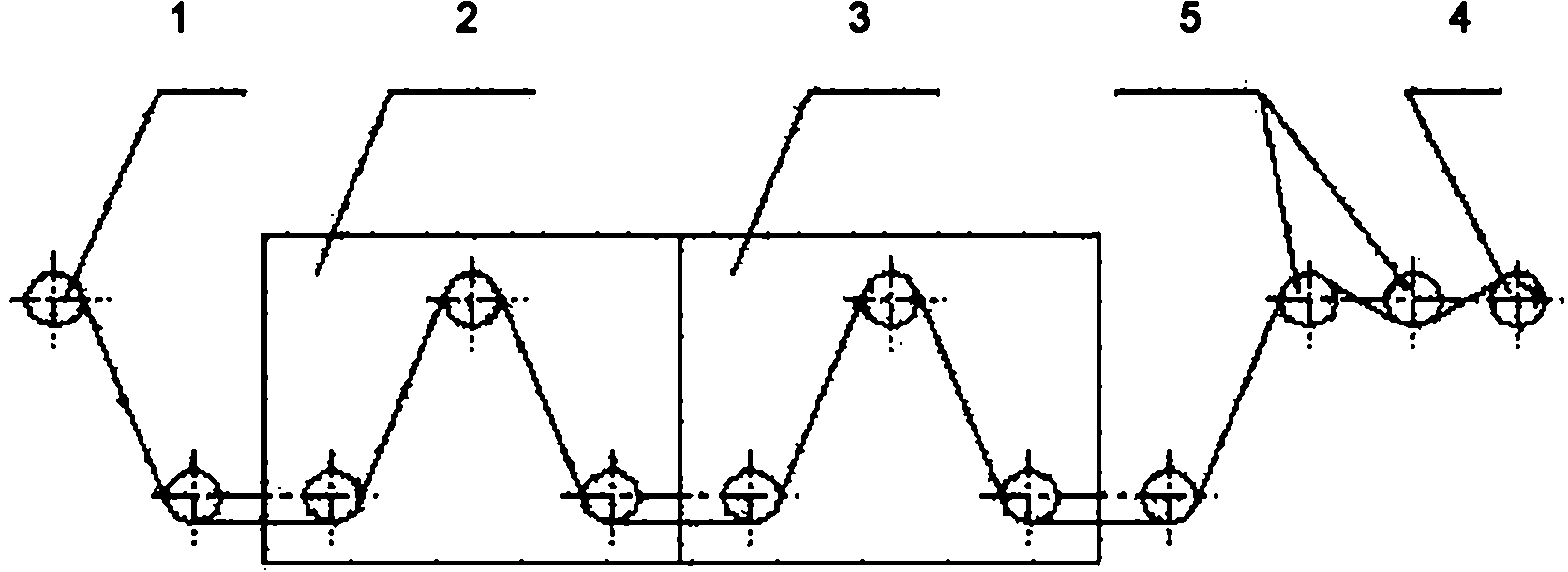

[0023] Described front tension frame (unwinding tension monitoring device) 2 such as image 3 As shown, it is composed of a fulcrum shaft, a swing arm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com