Sulfur hexafluoride gas separation and purification device and purification method thereof

A technology for sulfur hexafluoride gas and purification devices, applied in separation methods, chemical instruments and methods, perfluorocarbon/hydrofluorocarbon capture, etc., can solve the problem of low purity of sulfur hexafluoride gas and poor gas separation Thoroughness and other issues to achieve the effect of improving recovery rate, reducing impurity content, and improving separation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

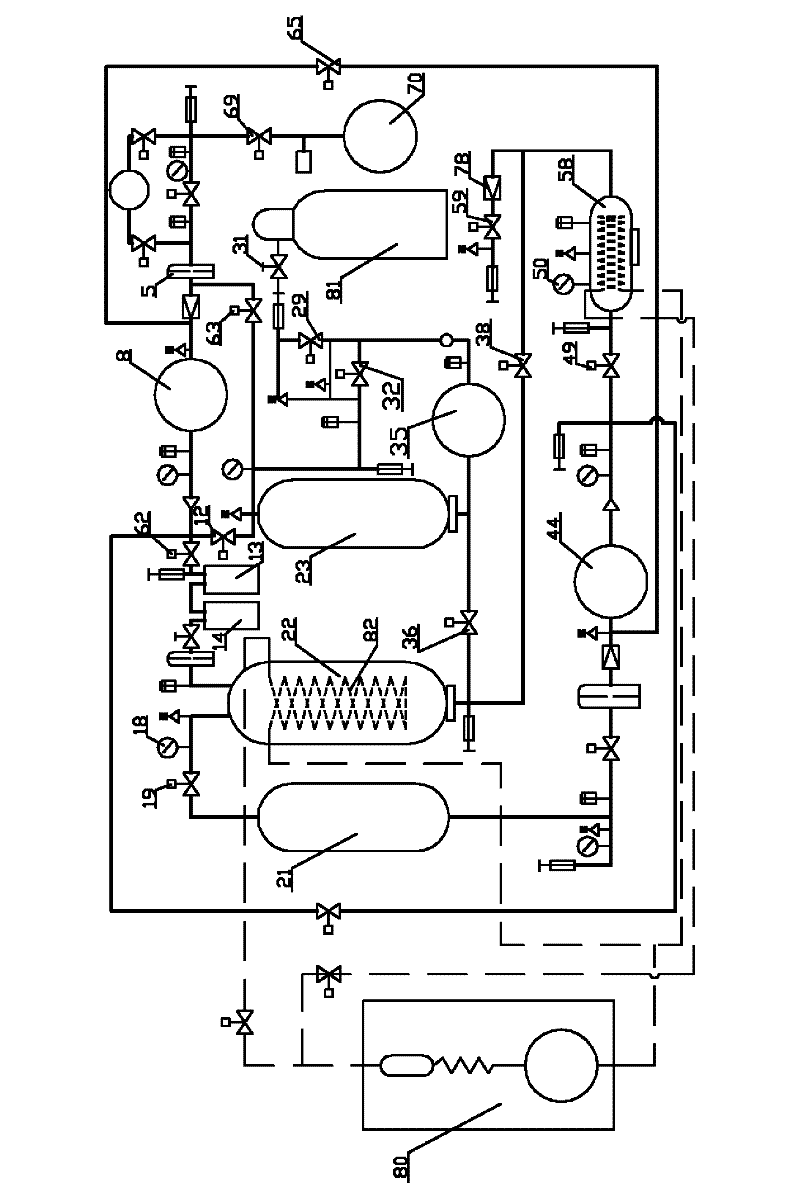

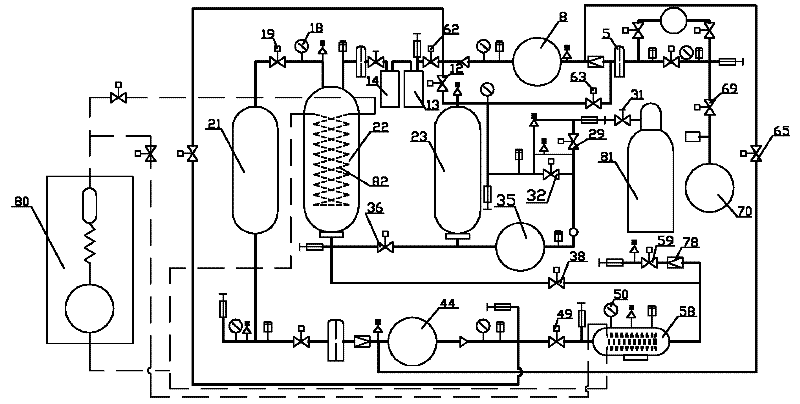

[0020] An embodiment of a sulfur hexafluoride gas separation and purification device, in figure 1Among them, the device includes a first separation container 22, a cooling medium channel 82 is arranged in the inner cavity of the first separation container 22, and the two ports of the cooling medium channel 82 of the first separation container 22 are respectively connected with the cooling medium outlet of the refrigeration unit 80 It communicates with the cooling medium inlet, and a first cut-off valve is provided between the cooling medium channel port of the first separation container 22 and the cooling medium outlet of the refrigeration unit 80 . The air inlet of the first separating container 22 is communicated with the air outlet of the first compressor 8, and the air inlet of the first compressor 8 is used for sulfur hexafluoride gas source to communicate, and the sulfur hexafluoride gas source here can be installed For the gas in the liquid storage cylinder, a low-fluor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com