Wind-power complementary pneumatic seawater desalting device

A wind power complementary, electric water pump technology, applied in wind power generation, seawater treatment, wind turbines, etc., to achieve the effect of high efficiency, alleviation of energy crisis, and reduction of energy conversion losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

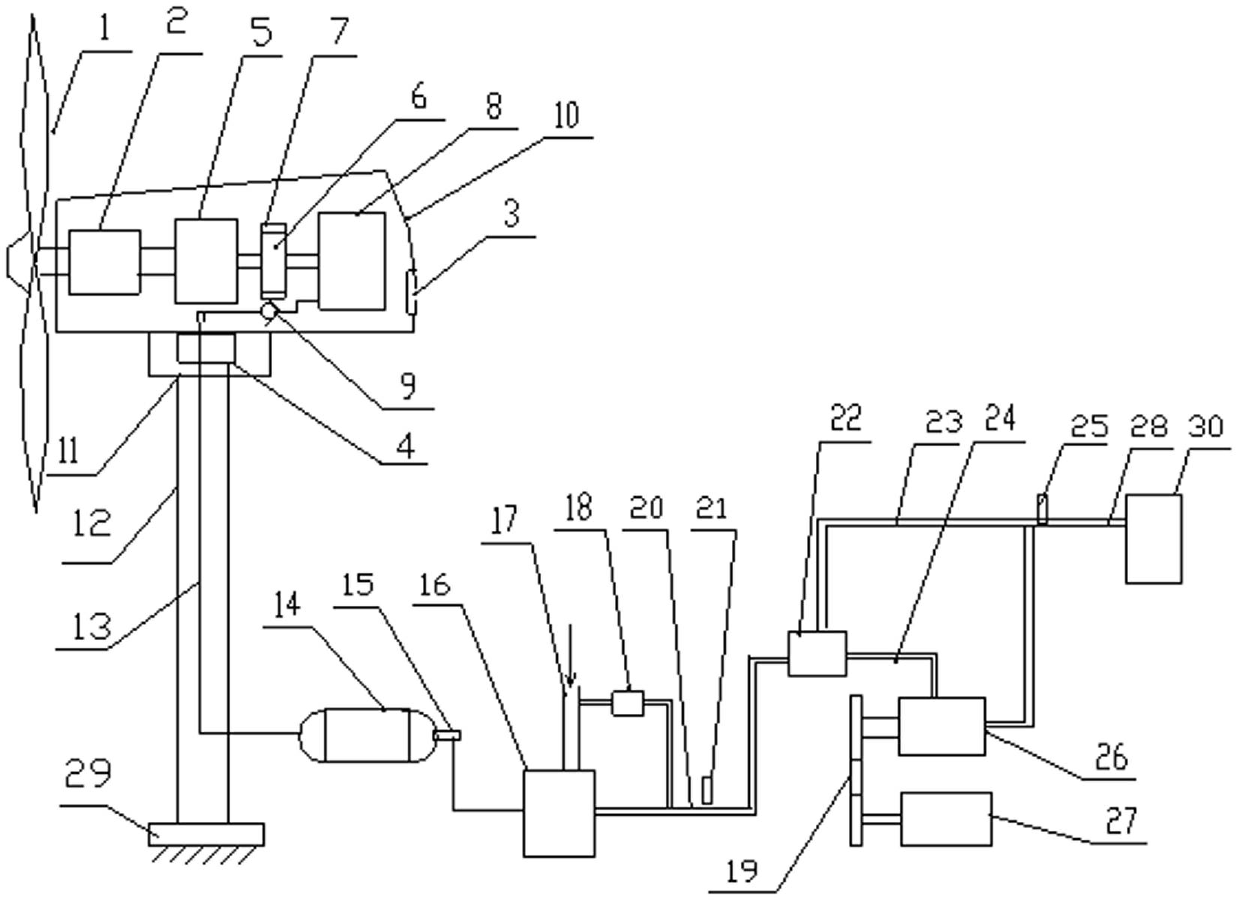

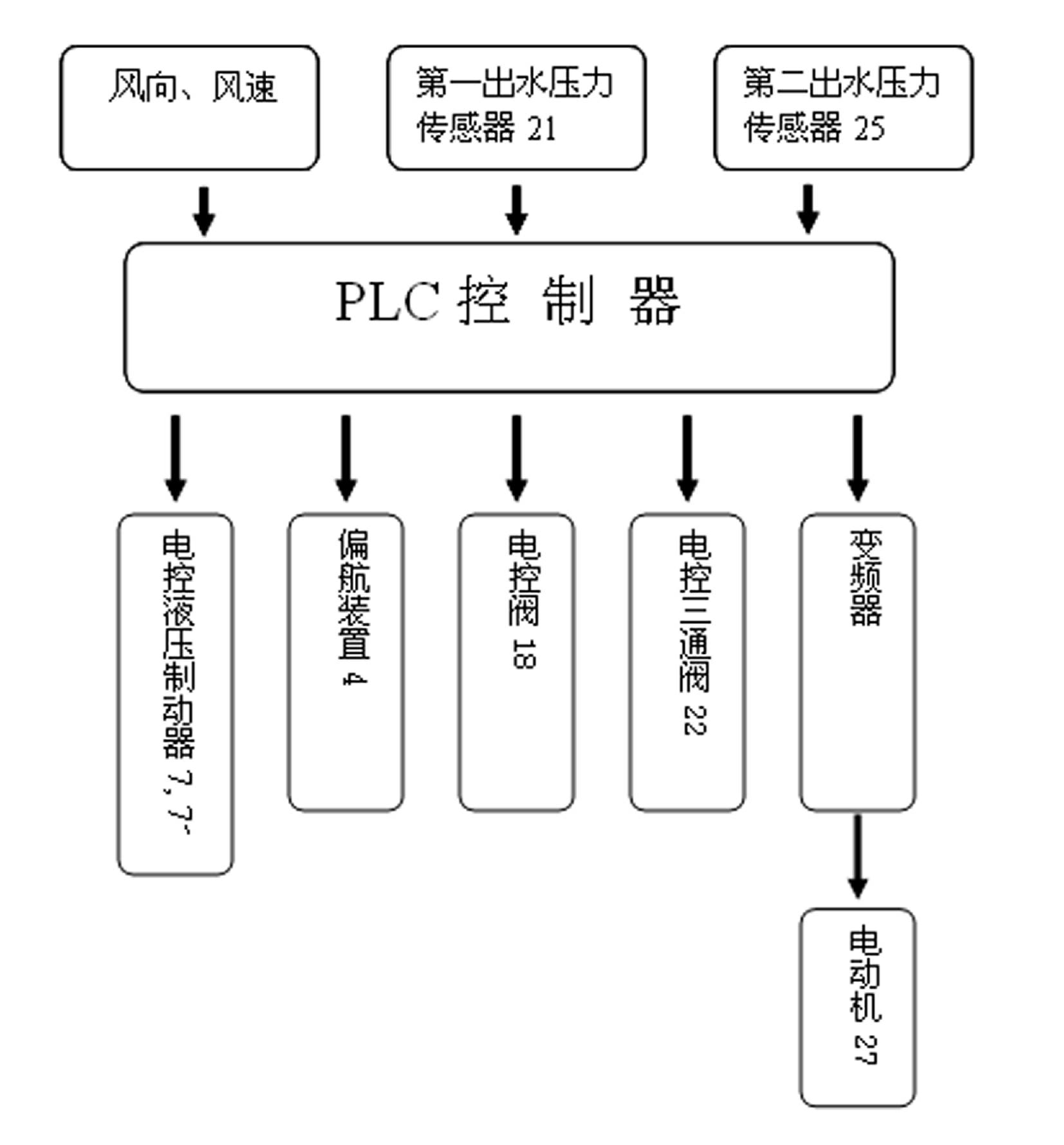

[0027] Such as figure 1 and image 3 As shown, it is a wind power complementary pneumatic seawater desalination device using a horizontal axis wind turbine impeller, including a pneumatic water pressure booster pump 16, an electric water pump 26, an air pipeline 13, and a wind-driven air compressor unit. The compressor unit includes a nacelle 10, an impeller 1 installed at the front of the nacelle 10, an impeller main shaft installed inside the nacelle 10, a supporting bearing 2 of the impeller main shaft, an acceleration gearbox 5, a coupling 6 and an air compressor 8, and the nacelle 10 The power transmission shafts inside are all connected by horizontal shafts.

[0028] The impeller main shaft is fixedly connected with the input shaft of the acceleration gearbox 5, and the output shaft of the acceleration gearbox 5 is fixedly connected with the main shaft of the air compressor 8 through a coupling 6, and the shaft coupling 6 An electronically controlled hydraulic brake 7 ...

Embodiment 2

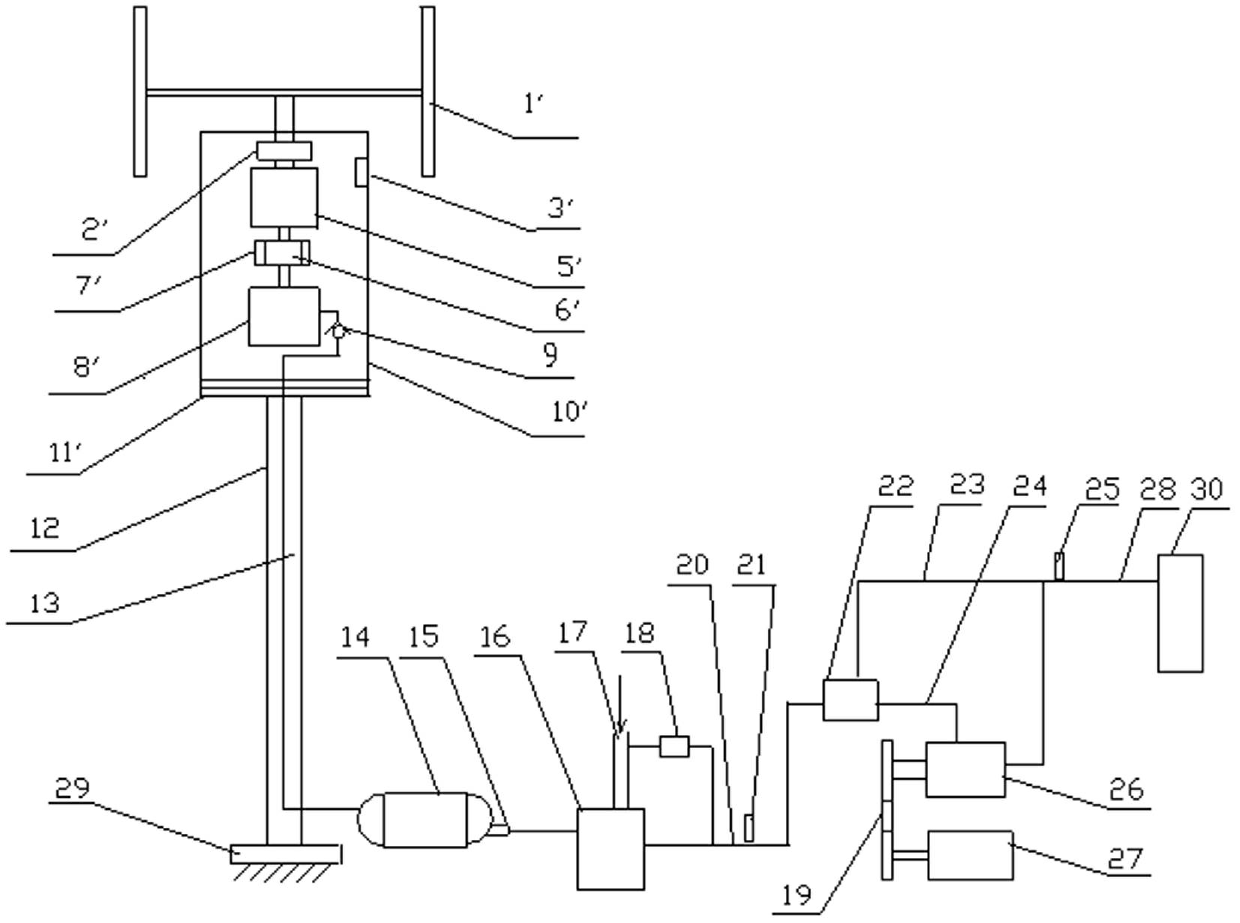

[0041] Such as figure 2 and image 3 As shown, it is a wind power complementary pneumatic seawater desalination device using a vertical axis wind turbine impeller, including a pneumatic water pressure booster pump 16, an electric water pump 26, an air pipeline 13, and a wind-driven air compressor unit. The compressor unit includes a nacelle 10', a wind turbine impeller 1' installed on the top of the nacelle 10', an impeller main shaft installed inside the nacelle 10', a support bearing 2' of the impeller main shaft, an acceleration gearbox 5', a coupling 6' and Air compressor 8 ', the power transmission shaft in its cabin all adopts vertical shaft connection. An air compressor inlet filter port 3' is provided on the nacelle 10'.

[0042] The main shaft of the impeller is fixedly connected with the input shaft of the acceleration gearbox 5', and the output shaft of the acceleration gearbox 5' is fixedly connected with the main shaft of the air compressor 8' through a couplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com