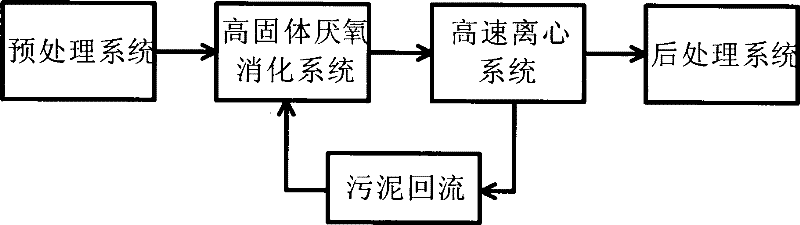

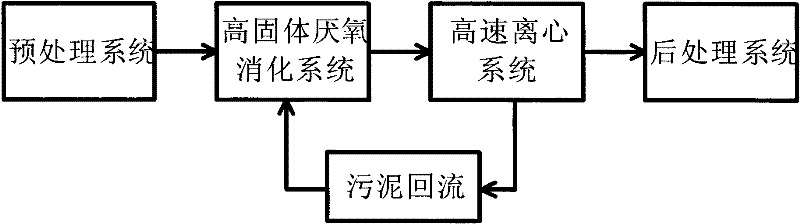

Biomass high solid anaerobic digestion process for separation and backflow of active sludge

An anaerobic digestion and activated sludge technology, applied in sludge treatment, biological sludge treatment, etc., can solve the problems of long hydraulic retention time, low load, and inability to separate sludge retention time and microorganism retention time, so as to improve utilization Efficiency, increased density, reduced hydraulic retention time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A biomass high-solids anaerobic digestion process for separating and returning activated sludge, comprising the following steps,

[0030] In the first step, add 250ml of kitchen waste into the CSTR anaerobic reactor with a volume of 5L, the feeding time is 30 minutes, the reaction time is 23 hours, and the material is discharged. The material discharge time is 30 minutes, and the total amount of material is 250ml;

[0031] In the second step, the discharge of the anaerobic reactor is centrifuged at a speed of 15000rpm for 15 minutes by a centrifuge, and after centrifugation, it is the supernatant liquid layer, the middle sludge layer and the remaining residue layer at the bottom;

[0032] The third step is to extract the supernatant of the upper layer, filter the remaining residue at the bottom layer, return the sludge layer in the middle to the CSTR anaerobic reactor, and add 250ml of kitchen waste to the anaerobic reactor again;

[0033] The fourth step, react for 23 ...

Embodiment 2

[0036] A biomass high-solids anaerobic digestion process for separating and returning activated sludge, comprising the following steps,

[0037] In the first step, 170ml of fruit and vegetable waste is added to the CSTR anaerobic reactor with a volume of 5L. The feeding time is 29 minutes, the reaction time is 22.5 hours, and the material is discharged. The material discharge time is 32 minutes, and the total material output is 170ml;

[0038] In the second step, the discharge of the anaerobic reactor is centrifuged at a speed of 12000 rpm for 10 minutes by a centrifuge, and after centrifugation, it is the supernatant liquid layer, the middle sludge layer and the remaining residue layer at the bottom;

[0039] The third step is to extract the supernatant of the upper layer, filter the remaining residue at the bottom layer, return the sludge layer in the middle to the CSTR anaerobic reactor, and add 170ml of fruit and vegetable waste to the anaerobic reactor again;

[0040] The...

Embodiment 3

[0043] A biomass high-solids anaerobic digestion process for separating and returning activated sludge, comprising the following steps,

[0044] In the first step, 200ml of straw is added to the CSTR anaerobic reactor with a volume of 5L. The feeding time is 33 minutes, the reaction time is 24 hours, and the material is discharged. The material discharge time is 35 minutes, and the total amount of material is 200ml;

[0045] In the second step, the discharge of the anaerobic reactor is centrifuged at a speed of 14000rpm for 10 minutes by a centrifuge, and after centrifugation, it is the supernatant liquid layer, the middle sludge layer and the remaining residue layer at the bottom;

[0046] The third step is to extract the supernatant of the upper layer, filter the remaining residue at the bottom layer, return the sludge layer in the middle to the CSTR anaerobic reactor, and add 200ml of fruit and vegetable waste to the anaerobic reactor;

[0047] The fourth step, react for 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com