Production process of lignin ammonium sulphonate as plant root growth regulator

A technology of ammonium lignosulfonate and growth conditioner, applied in fertilizer mixture, fertilization device, application and other directions, can solve problems such as unfavorable plant root growth, low fertilizer utilization rate, arable land formation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

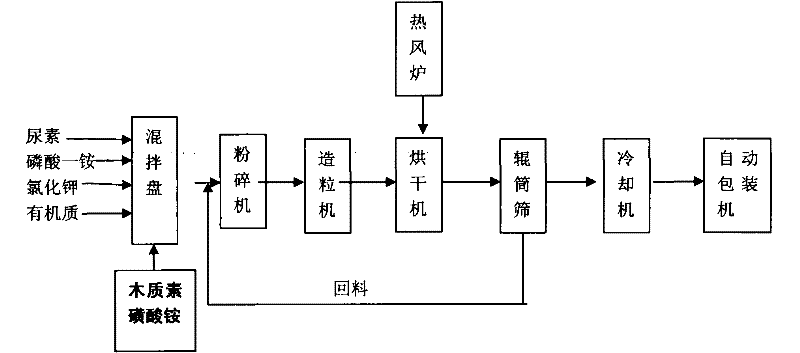

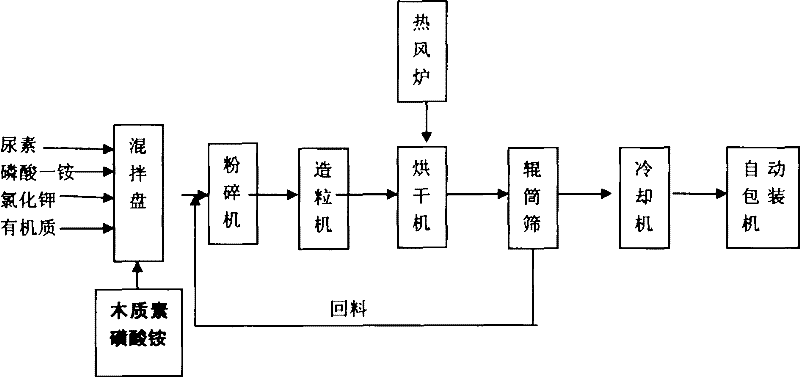

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

[0018] Ammonium lignosulfonate as plant root growth conditioner production technology formula is:

[0019] Organic fertilizer formula: add 50% of organic raw materials with organic matter ≥ 60%, 35% of straw ash for power generation, 10% of attapulgite, and 5% of ammonium lignosulfonate. The product implements the national agricultural NY525-2002 standard, N+P 2 o 5 +K 2 O≥5%, organic matter≥30%.

[0020] Inorganic compound fertilizer formula: urea 30%, monoammonium phosphate 25%, potassium chloride 20% with potassium oxide content 60%, ammonium sulfate 5%, medium and trace elements 5%, attapulgite 10%, ammonium lignosulfonate 5%. The product implements GB15063-2009 standard, N+P 2 o 5 +K 2 O≥40%.

[0021] Organic-inorganic compound fertilizer formula: 10% urea, 15% monoammonium phosphate, 25% ammonium chloride, 11% potassium chloride, 5% ammonium sulfate, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com