Non-destructive evaluation method for nonlinear characteristic parameters of hydro-pneumatic suspension

A technology of oil-pneumatic suspension and characteristic parameters, which is applied in the direction of elastic testing, machine/structural component testing, vehicle suspension/shock-absorbing mechanism testing, etc. It can solve problems such as cumbersome testing methods, inconsistent use conditions, and difficult implementation of testing. Achieve fast and effective characteristic parameters and performance, strong practicability, and rapid evaluation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] The present invention is based on the existing oil-gas suspension bench test and test, based on the reverse calculation technology, only one dynamic test is carried out, and through continuous iterative calculations, the displacement-elastic force, speed-damping of the oil-gas suspension can be calculated A one-time overall evaluation of the two nonlinear characteristics of force.

[0031] Such as Figure 4 Shown, concrete steps of the present invention are as follows:

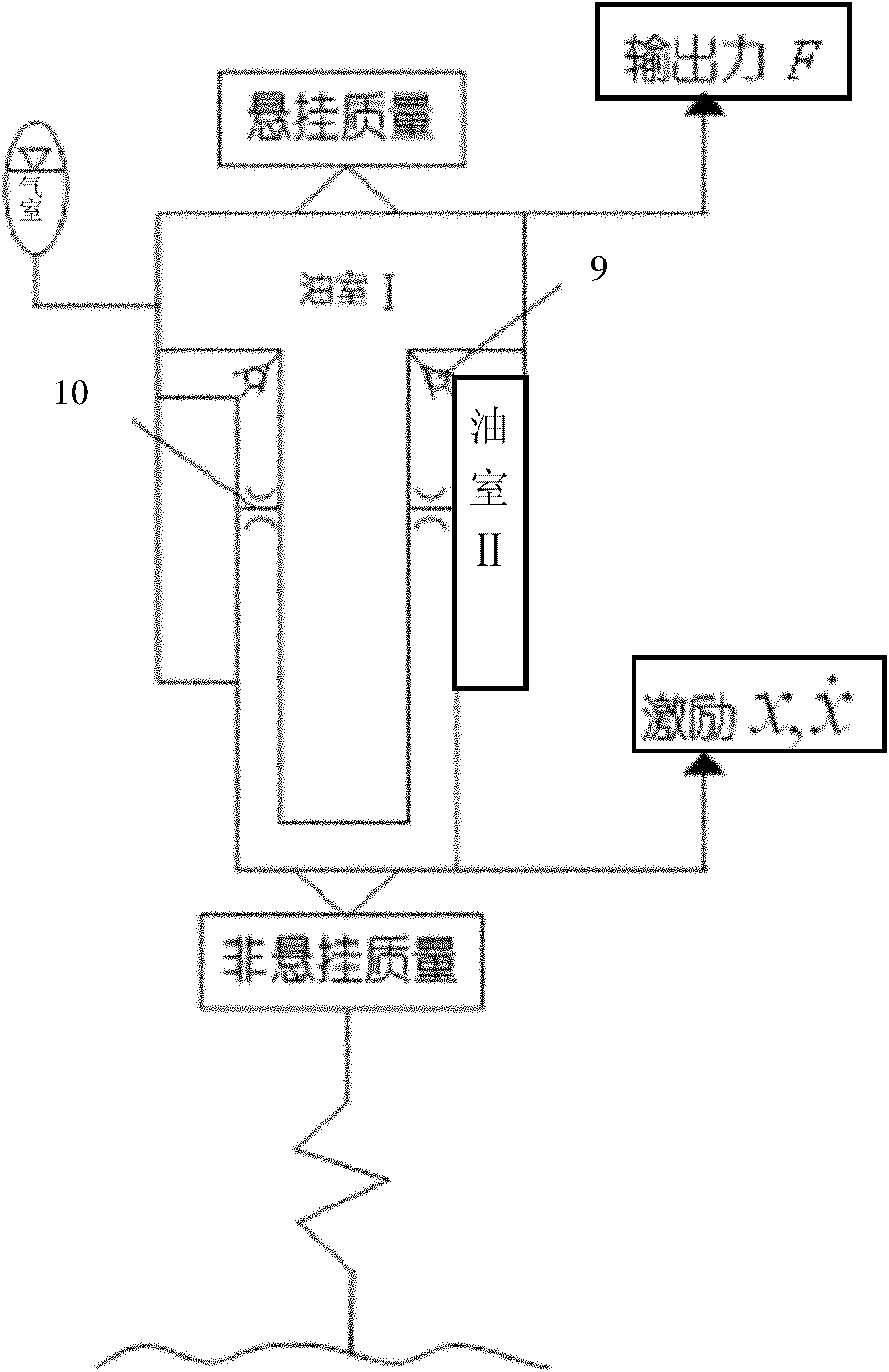

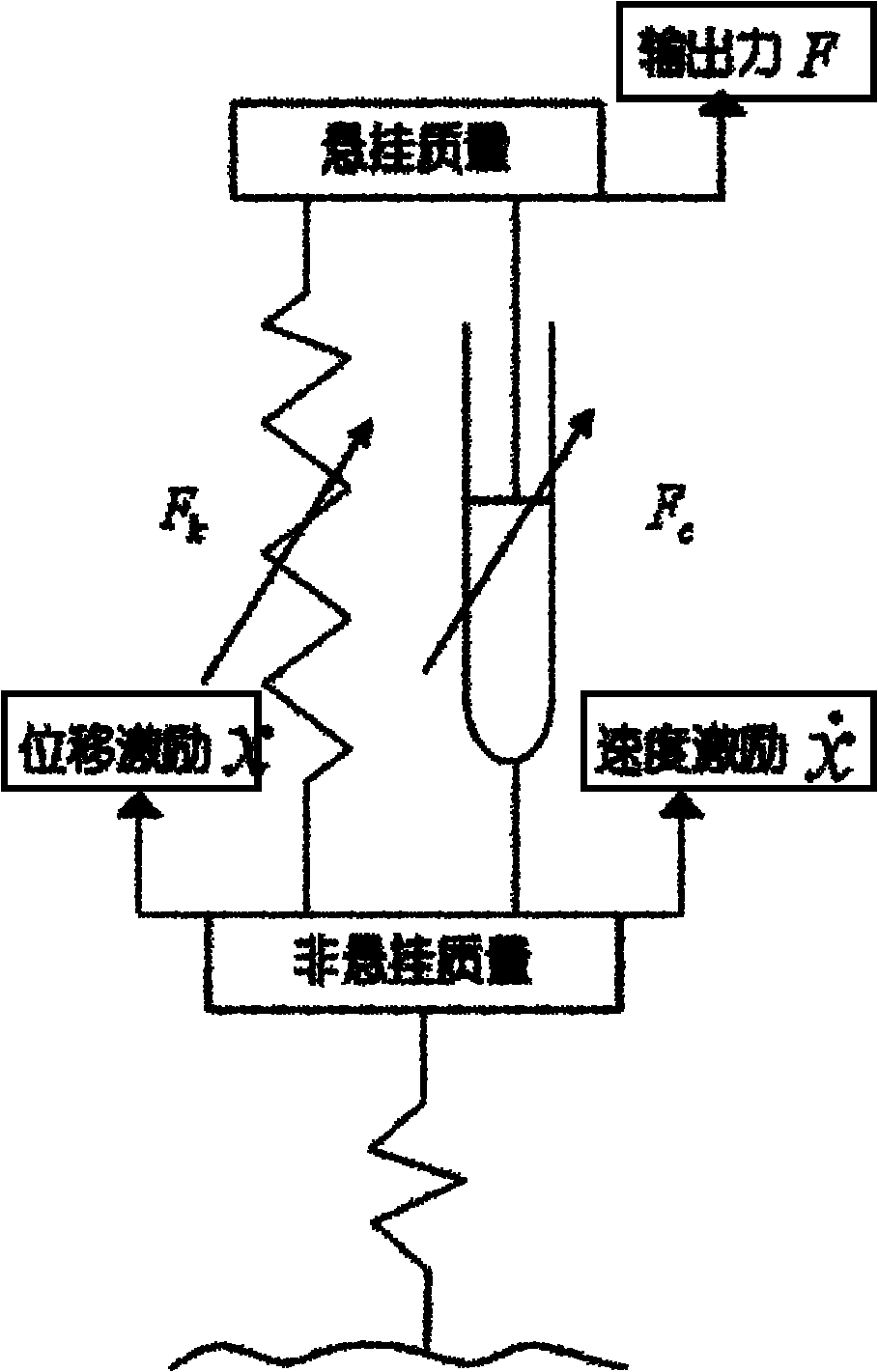

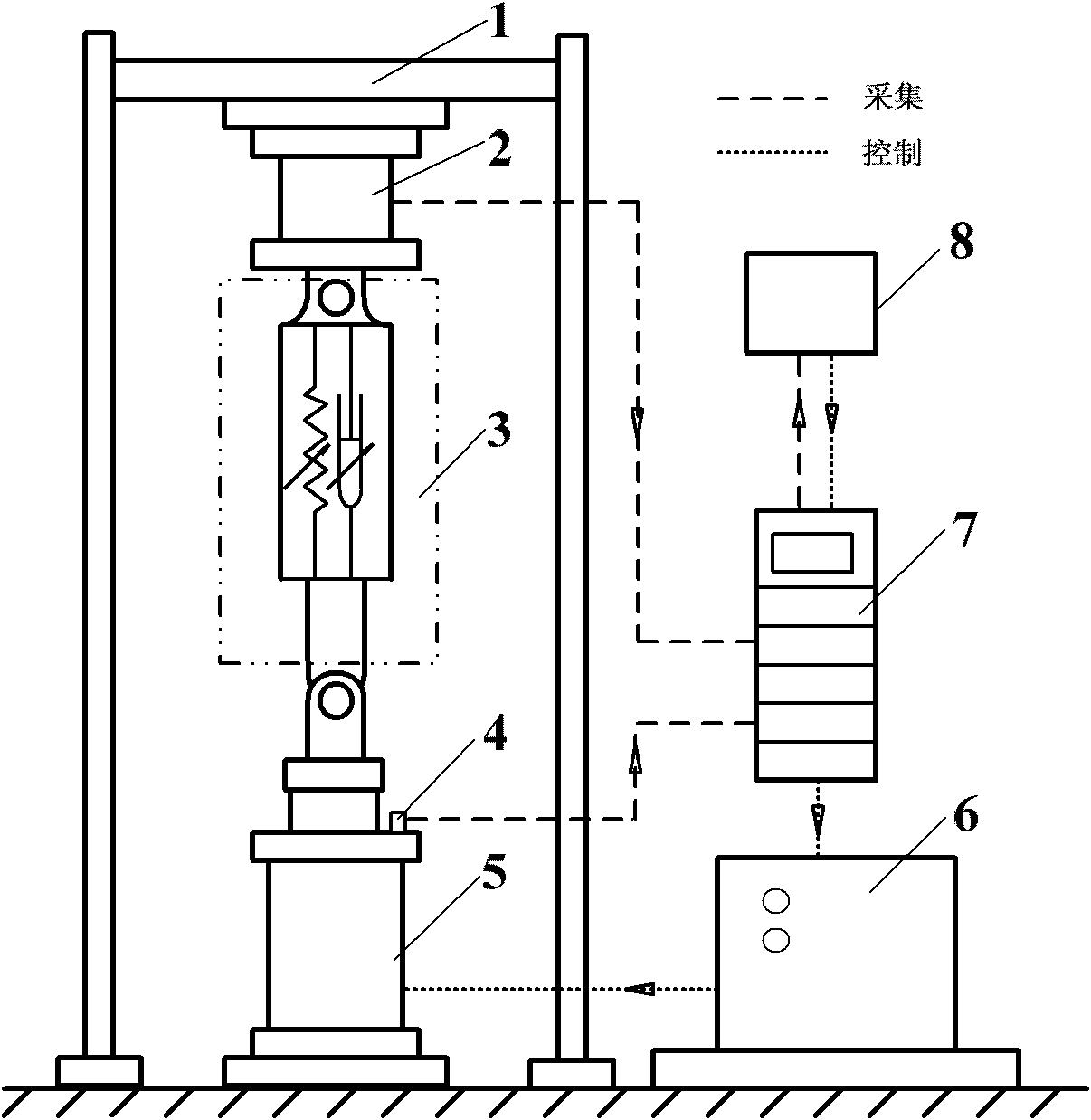

[0032] Step 1: Build image 3 The bench test test system of the traditional oil-pneumatic suspension is shown, and a dynamic test is carried out, and each time t is obtained by measuring the displacement, velocity and force sensors i The displacement excitation x(t i ), speed incentive and output force F m (t i ).

[0033] Step 2: The present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com