Ammonia spraying grate and adjusting method thereof

A technology of ammonia injection grid and adjustment method, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of large adjustment dead zone, slow flow rate change, and high adjustment requirements, and achieve the adjustment range without dead ends. area, to achieve the effect of flow size and flow change continuous

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

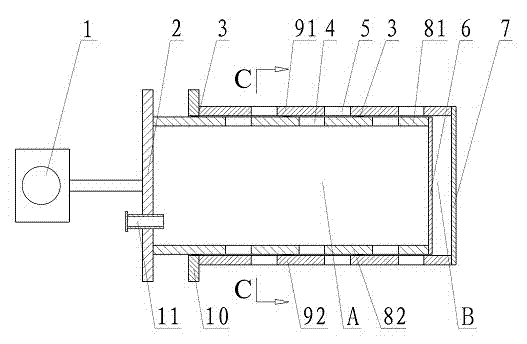

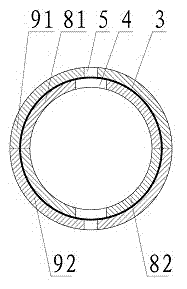

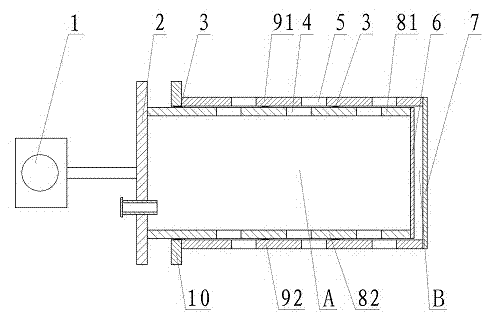

[0018] see Figure 1~3 As shown, the ammonia spray grid includes an upper outer sleeve 91, a lower outer sleeve 92 opposite to the upper outer sleeve 91, an upper inner sleeve 81 nested in the upper outer sleeve 91, and an upper inner sleeve 81 nested in the lower outer sleeve 92. Inside the lower inner casing 81.

[0019] One end of the upper outer casing 91 and the lower outer casing 92 is connected through the outer casing cover plate 7, and the other end of the upper outer casing 91 and the lower outer casing 92 is provided with an outer casing flange 10; the upper inner casing 81 and the lower inner casing One end of 82 is connected by inner casing cover plate 6, and the other end of upper inner casing 81 and lower inner casing 82 is provided with inner casing flange 2, upper inner casing 81, lower inner casing 82, inner casing The cover plate 6 and the inner sleeve flange 2 form a cavity A; there is a gap B between the inner sleeve cover plate 6 and the outer sleeve cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com