Micro electromechanical device and manufacturing method thereof

A technology of a microelectromechanical device and a manufacturing method, which are applied in the directions of microstructure devices, processing microstructure devices, measuring devices, etc., can solve the problems of low integration, inability to meet portability, and large size of microelectromechanical devices, and meet the requirements of portability. performance, reduce volume, and improve integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

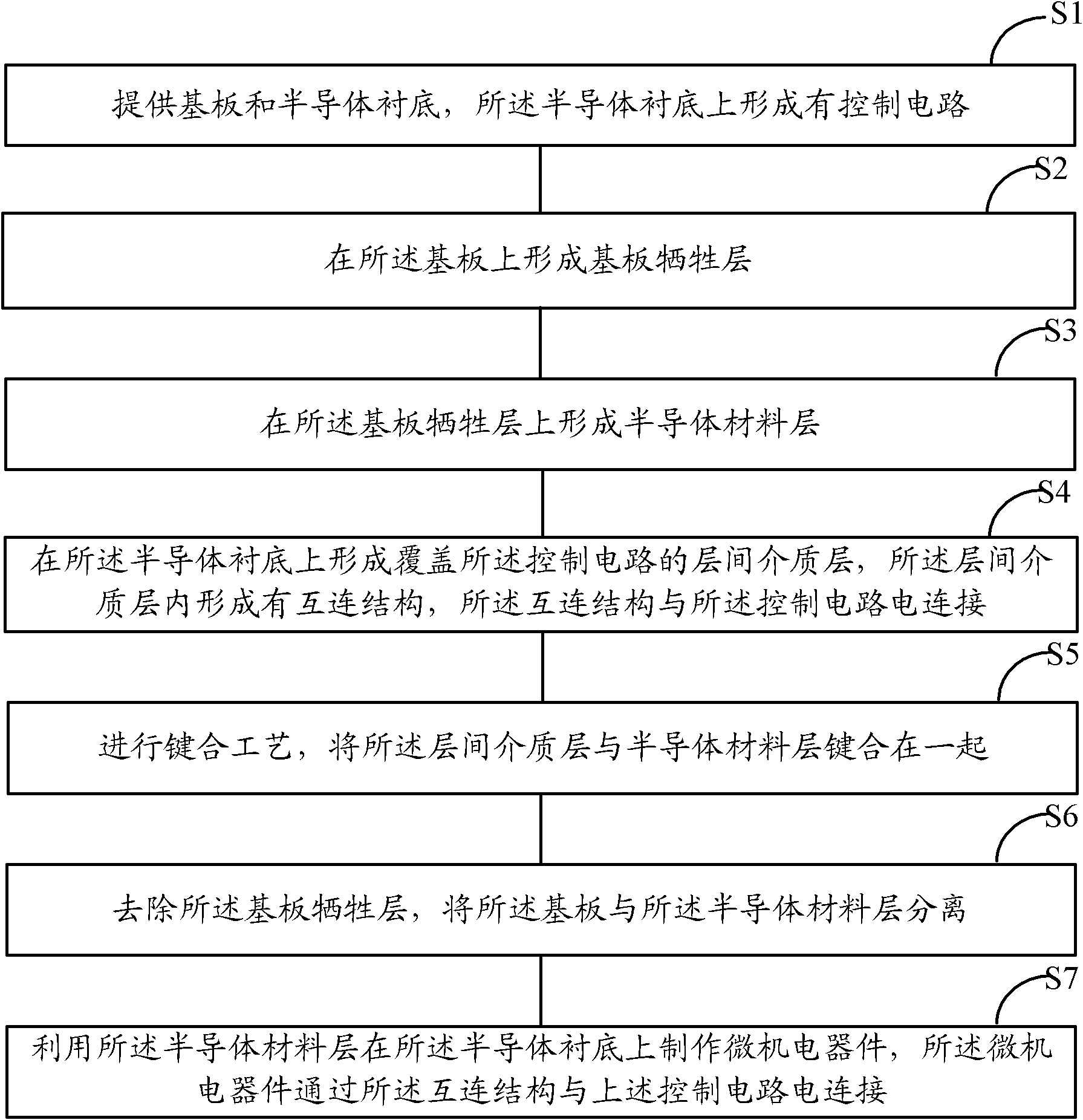

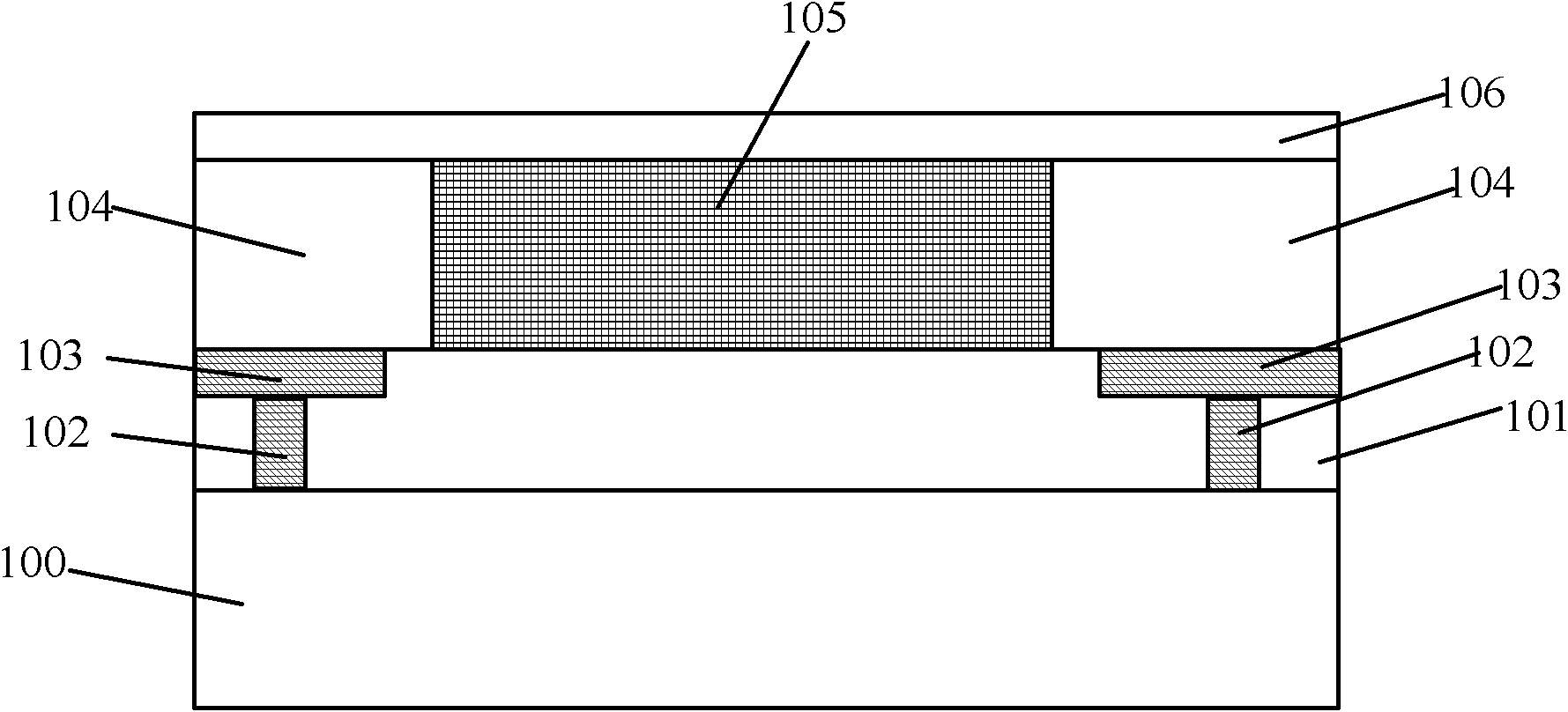

[0051] The micro-electro-mechanical device of the prior art is made by two semiconductor substrates, one of which is used to make a control circuit, and the other semiconductor substrate is used to make a micro-electro-mechanical device, and then the two semiconductor substrates are arranged side by side on the lead Therefore, the existing micro-electro-mechanical devices are large in size, so the integration degree of the micro-electro-mechanical devices is not high, and cannot meet the requirements of portability in applications. Moreover, in the prior art, two semiconductor substrates are used to fabricate one MEMS device, and the cost is relatively high.

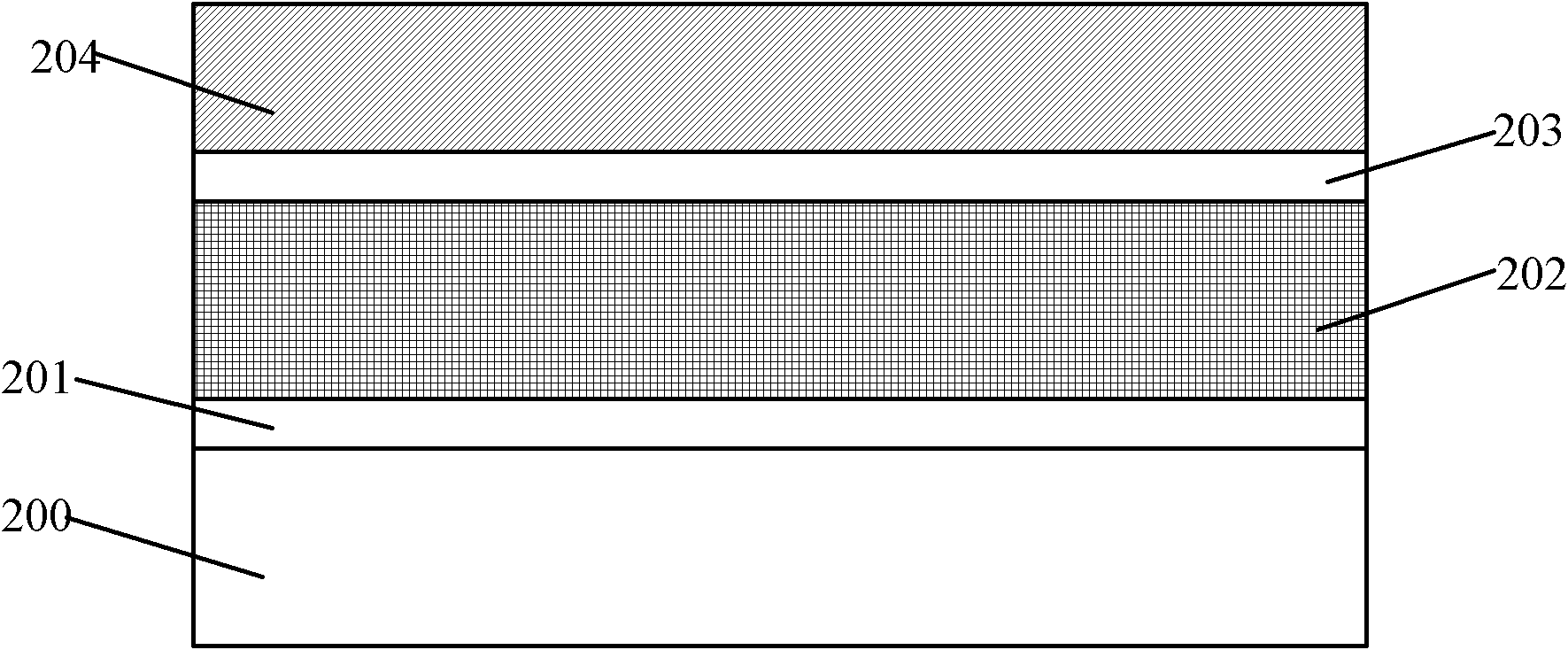

[0052] Since the material of the movable electrode of the MEMS device is generally a semiconductor material layer, the semiconductor material layer may be a polysilicon layer, and the polysilicon layer is usually produced by a chemical vapor deposition process, and the temperature of the chemical vapor deposition process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com