Continuous sedimentation full-range urea dewaxing method of wax-bearing oil

A urea dewaxing and full fraction technology, which is applied in the petroleum industry, petroleum wax recovery, mineral wax recovery/refining, etc., to achieve good dewaxing effect, strong equipment coordination, and easy operation and control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

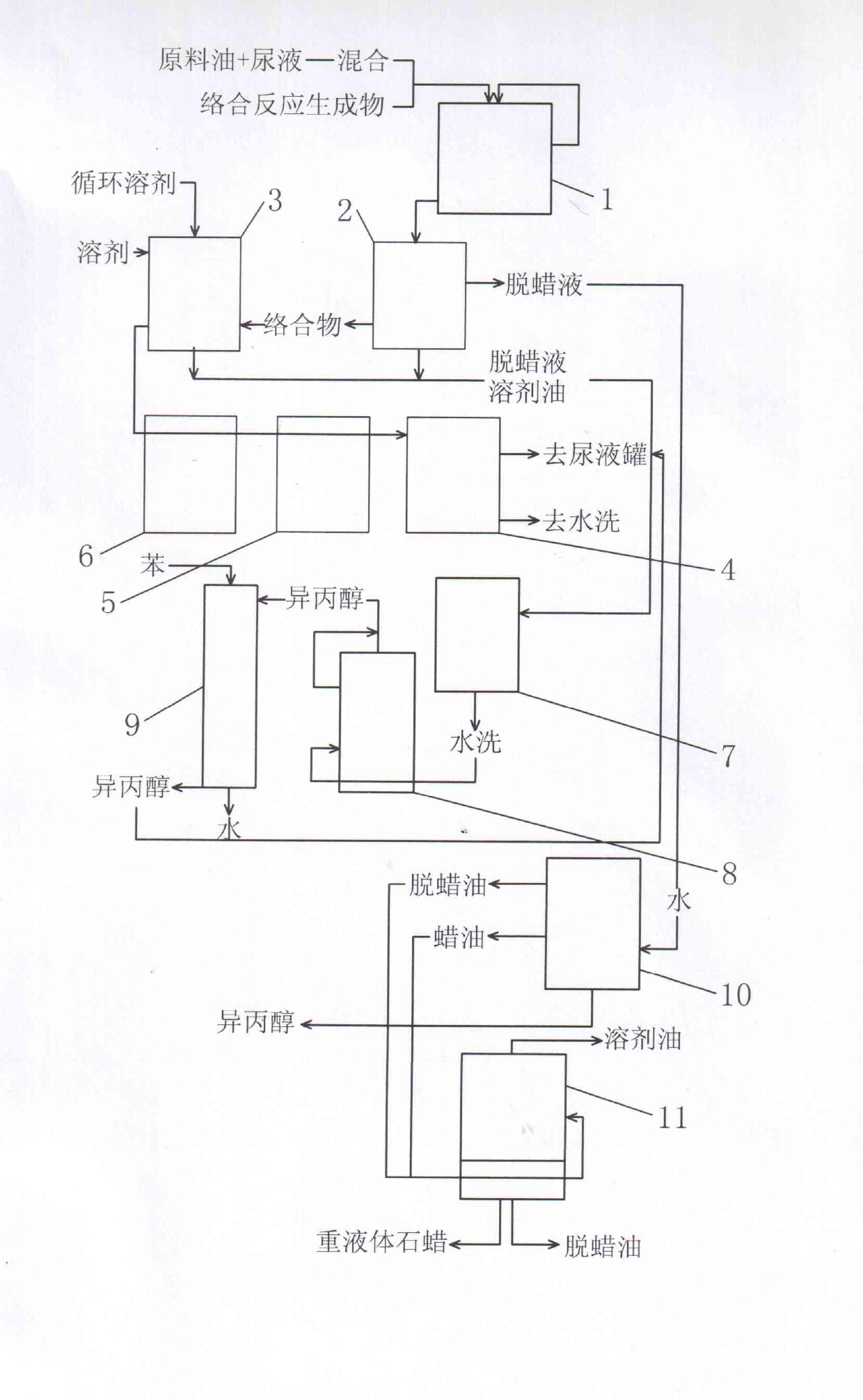

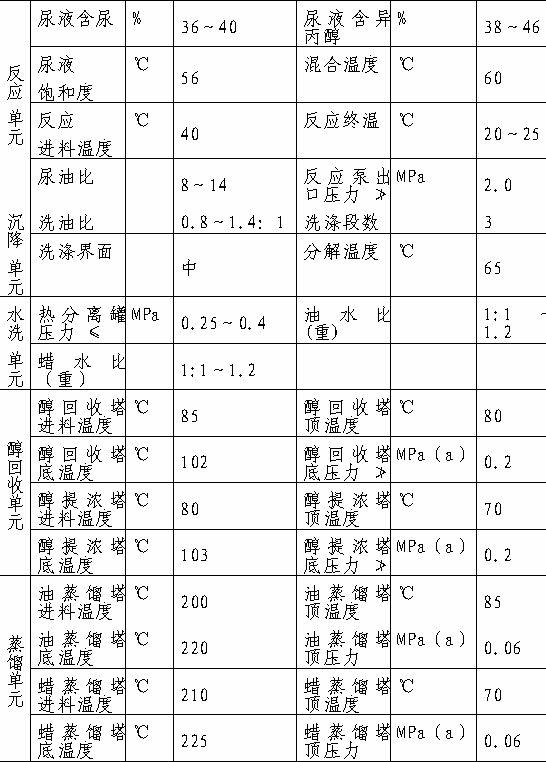

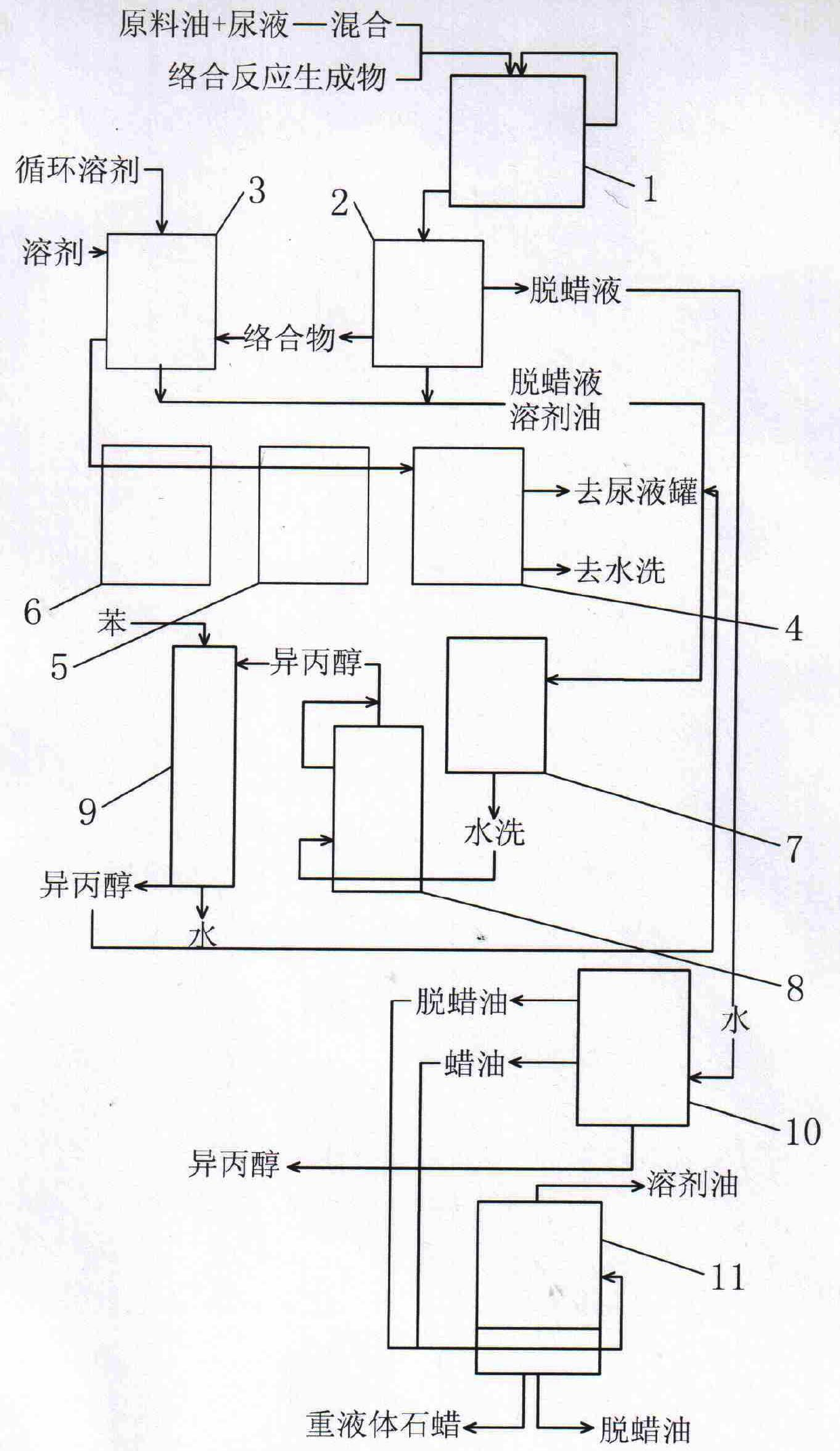

[0043] The dewaxing process includes complexation reaction, complex sedimentation washing, complex decomposition, solvent separation and recovery and distillation unit composition.

[0044] The rotary scraper type pipeline complexation reactor is adopted to solve the problem of the complex compound blocking the pipeline and hindering the export of reaction heat, and realizes the slow stirring gravity sedimentation separation process of the complex compound and the multi-stage countercurrent washing refining process of solvent oil.

[0045] The actual operation test shows that compared with the isopropanol dewaxing process, the process flow is continuously simplified by using the continuous dewaxing method of full-fraction urea dewaxing by sedimentation method, from the initial 17 units to 12 units; the energy consumption of the device is continuously reduced, by The initial 374KgEo / t feedstock oil is reduced to 120KgEo / t feedstock oil; material consumption is continuously reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com