Modified cotton fiber felt and application thereof

A technology for modifying cotton and fiber mats, applied in the field of modified cotton fiber mats, can solve problems such as inability to bond with other materials, inability to form, and achieve the effects of reducing material costs, odors, and costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

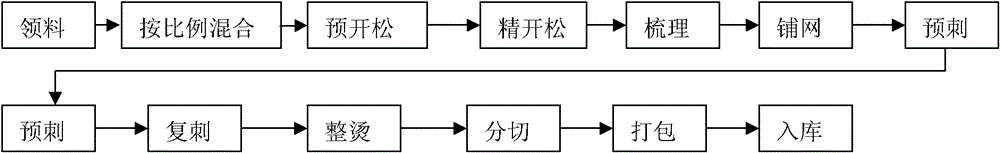

[0057] Mix 20% cotton fiber, 40% low-melting point PET fiber, and 40% polypropylene fiber in proportion, and then go through pre-opening, fine opening, carding, web laying, pre-punching, double-punching, ironing, and then cut and pack That is, the modified cotton fiber felt is obtained.

[0058] It is used to prepare sound-insulating and heat-insulating pads. The modified cotton fiber felt is sent to a far-infrared heating furnace, and the far-infrared hot air is circulated and heated. The heating temperature is 250°C, and the heating time is 30 seconds. Then it is sent into the mold, and the cotton fiber is modified by heating It is molded under the action of a press, and at the same time cooled by the mold (cooling water is passed through the mold) and formed to obtain a sound-insulating and heat-insulating pad. The product is pollution-free and has good fastness. Use an acoustic tester (8-channel standing wave tube) to test its sound-absorbing performance, as attached Im...

Embodiment 2

[0060] Mix 90% cotton fiber, 5% low-melting point PET fiber, and 5% polypropylene fiber in proportion, and then go through opening, fine opening, carding, web laying, pre-punching, re-punching, ironing, and then slitting and packing. The modified cotton fiber mat is obtained.

[0061] It is used to prepare sound-insulating pad parts, and the modified cotton fiber felt is sent to a far-infrared heating furnace, heated by far-infrared hot air circulation, the heating temperature is 200 ° C, and the heating time is 60 seconds. Rubber and Plastic Co., Ltd.) is also moved into the far-infrared heating furnace, and the far-infrared hot air is circulated for heating. The heating temperature is 200 ° C, and the heating time is 20 seconds. The heated EVA soft board is sent into the mold and spread on the lower mold. The modified cotton fiber felt is sent between the upper mold and the lower mold of the mold, and spread on the heated EVA soft board, the press is started, molded under th...

Embodiment 3

[0063] Mix 50% cotton fiber, 30% low-melting point PET fiber, and 20% polypropylene fiber in proportion, and then go through pre-opening, fine opening, carding, web laying, pre-punching, double-punching, ironing, and then cut and pack That is, the modified cotton fiber felt is obtained.

[0064] It is used to prepare sound-insulating and heat-insulating pads, and the modified cotton fiber mat is sent to a far-infrared heating furnace, heated by far-infrared hot air circulation, the heating temperature is 250 ° C, and the heating time is 30 seconds. At the same time, PP wood powder board (Jiangsu Zhong Hong Machinery Co., Ltd.) is also moved into the far-infrared heating furnace, and the far-infrared hot air is circulated for heating. The heating temperature is 250°C and the heating time is 30 seconds. The final modified cotton fiber felt is sent between the upper mold and the lower mold of the mould, and spread on the heated PP wood powder board, the press is started, molded u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com