Method and device for diagnosing and calibrating faults in high-pressure common rail system

A high-pressure common rail system and fault technology, applied in the direction of measurement device, charging system, fuel injection device, etc., can solve the problems of rough compensation and neglect, and achieve the effect of configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

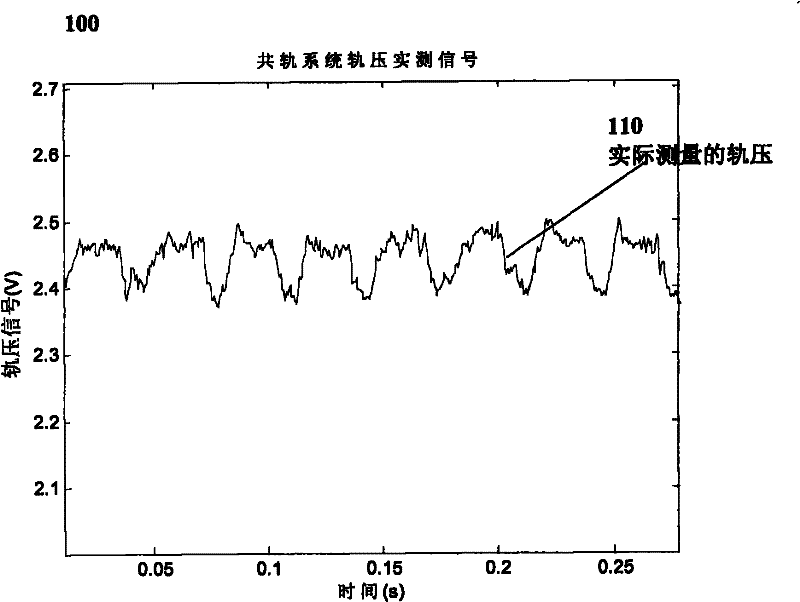

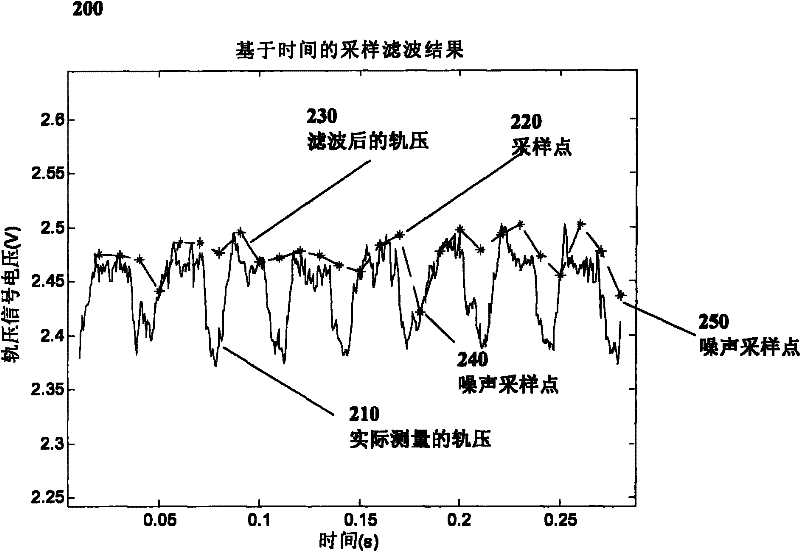

Image

Examples

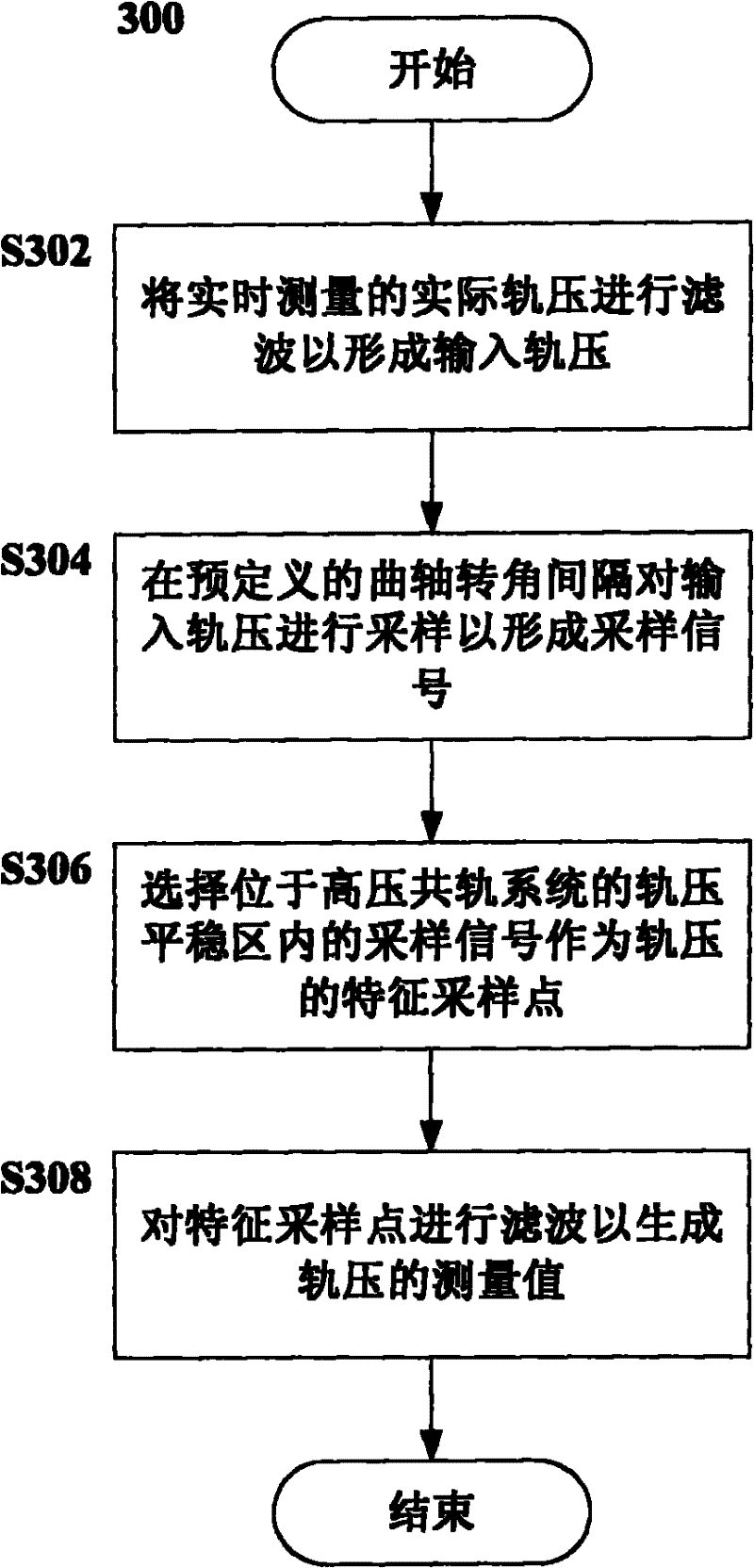

Embodiment Construction

[0033] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The flowchart and block diagrams in the Figures illustrate the architecture, functionality, and operation of possible implementations of systems, methods and computer program products according to various embodiments of the present invention. In this regard, each block in a flowchart or block diagram may represent a module, program segment, or portion of code that contains one or more logic devices for implementing the specified Executable instructions for a function. It should also be noted that, in some alternative implementations, the functions noted in the block may occur out of the order noted in the figures. For example, two blocks shown in succession may, in fact, be executed substantially concurrently, or they may sometimes be executed in the reverse order, depending upon the functionality involved. It should also be noted that each block of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com