Valve stroke testing system

A testing system and valve stroke technology, applied in valve devices, measuring devices, instruments, etc., can solve the problems of expensive valves, wear of sealing surfaces, internal leakage of valves, etc., to achieve accurate and reliable test results, avoid adverse effects, and avoid valve damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

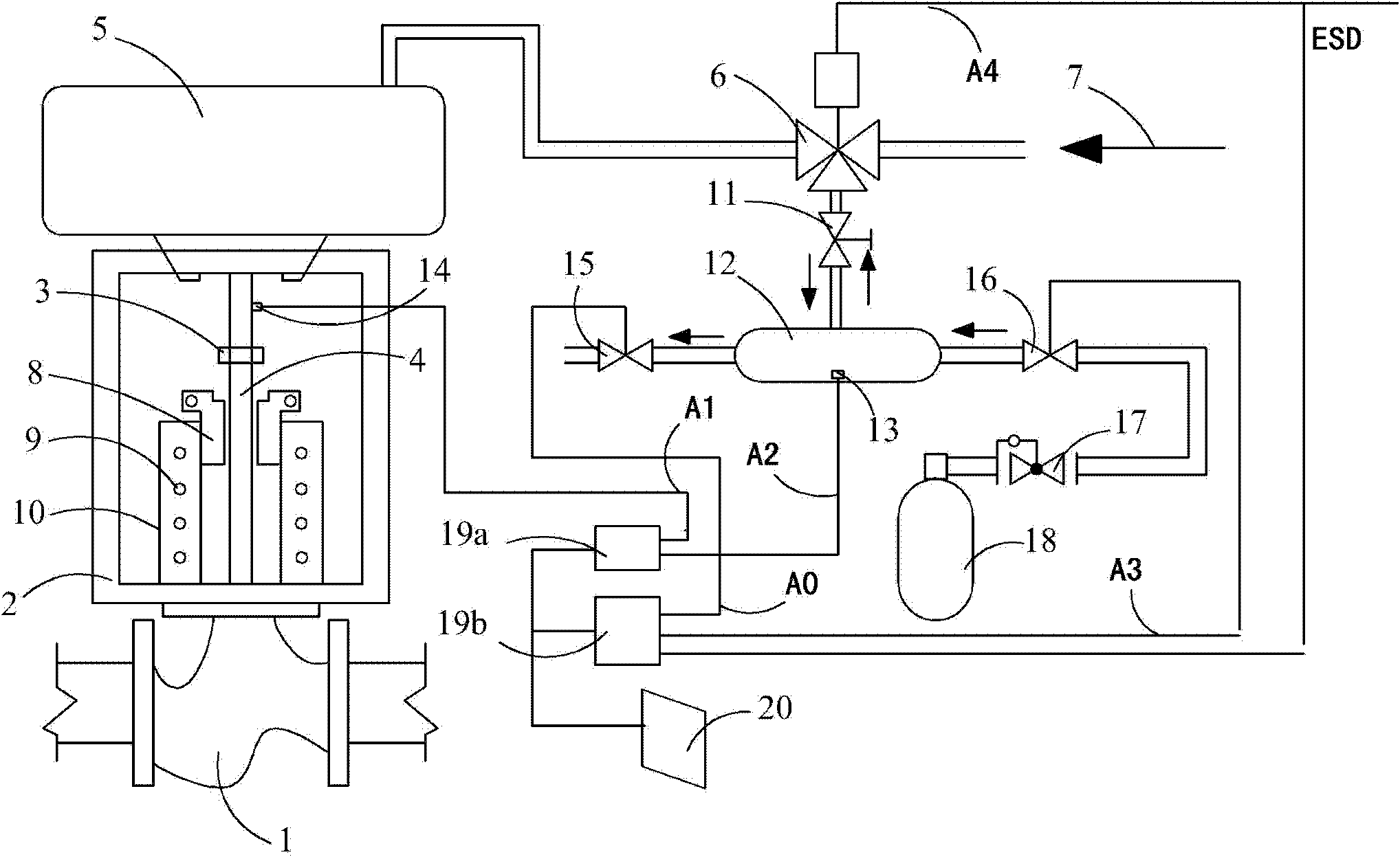

[0051] see figure 1 , the system configuration in this embodiment includes a measured valve, an intake and exhaust device, and a detection unit;

[0052] The structural setting of the tested valve includes: controlling the instrument air 7 to enter the air intake into the pneumatic actuator 5 through the two-position three-way solenoid valve 6, or controlling the exhaust of the pneumatic actuator 5 to drive the pneumatic actuator 5; A sensing unit 14 for relevant information of the valve stem 4, the sensing unit 14 includes a speed sensor for detecting the movement speed of the valve stem, an acceleration sensor for detecting the movement acceleration of the valve stem, and a displacement sensor for detecting the displacement of the valve stem;

[0053] The structural setting of the intake and exhaust device includes: one way of the buffer tank 12 is connected with the external instrument air tank 18 through the intake solenoid valve 16 and the pressure reducing valve 17 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com