Electrodes for high pressure in situ resistivity survey and manufacturing method of electrodes

An in-situ resistance and electrode technology, applied in the field of high-voltage devices, can solve problems such as measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

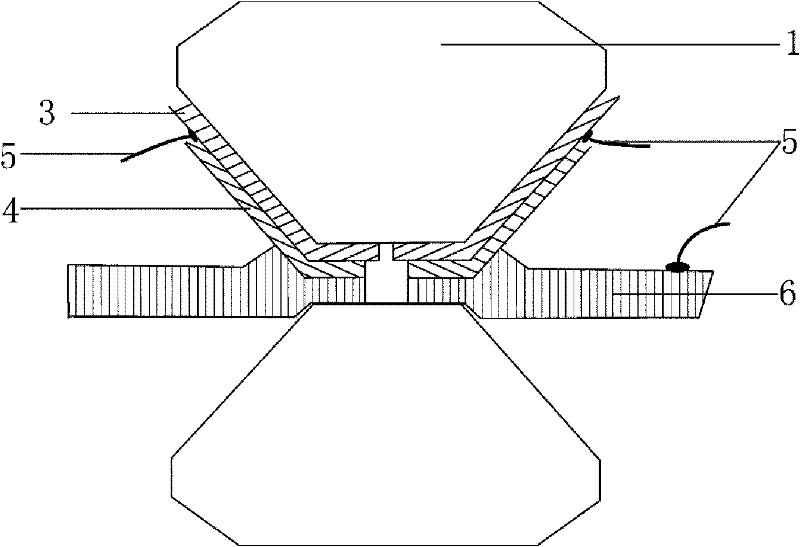

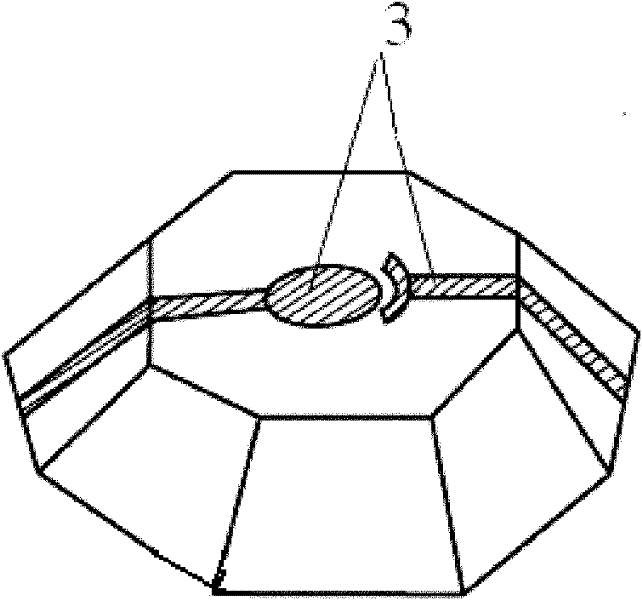

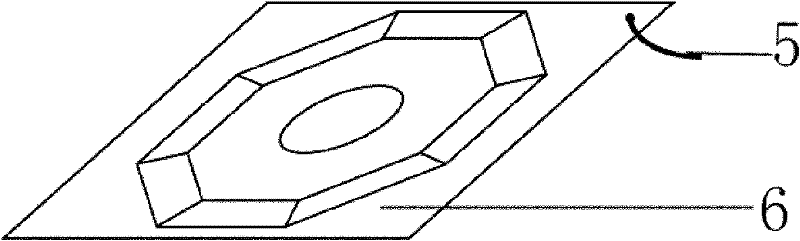

[0022] Embodiment 1 illustrates the electrode structure of the present invention in conjunction with the accompanying drawings

[0023] exist figure 1 , 2 , 3, 1 is a diamond anvil, 3 is an electrode, 4 is an insulating protective layer, 5 is a metal lead, and 6 is a metal gasket.

[0024] See figure 2 , the two electrodes 3 extend from the anvil surface of the diamond anvil 1 to the side respectively; the ends of the two electrodes 3 on the anvil surface of the diamond anvil 1 are respectively circular and arcuate, and the arcuate ends surround two sides of the circular end The ends of the strip electrode 3 on the anvil surface of the diamond anvil 1 are circular and arcuate respectively, and the arcuate end surrounds the outside of the circular end. The molybdenum electrode formed by the inventor on the anvil surface of diamond anvil 1 with a radius of about 150 μm is divided into two parts, one is the round electrode at the end, and the radius of the round electrode is ...

Embodiment 2

[0027] Embodiment 2 illustrates the fabrication process of the electrode of the present invention in conjunction with the accompanying drawings

[0028] The present invention utilizes thin film deposition technology and photolithography to integrate metal microcircuits on the anvil surface of diamond, and the whole process of making electrode 3 can be found in Figure 4 , completed by the following technological means:

[0029] (1) First put the diamond anvil 1 into the acid solution (the ratio of sulfuric acid to nitric acid is 1:1) and cook for 20 to 30 minutes to remove the stains attached to the diamond surface, and then rinse off the remaining stains on the surface of the anvil with deionized water. acid. Figure 4 The cleaned diamond counter-anvil is shown in the upper left part of the center.

[0030] (2) After the diamond anvil 1 is dried, it is put into the vacuum chamber of the magnetron sputtering device, and metal molybdenum is deposited on the diamond surface by...

Embodiment 3

[0037] The selection of embodiment 3 electrode shape:

[0038] According to the Laplace equation of the electrostatic field:

[0039] Laplace's equation for cylindrical coordinates: and is U 1 , U 2 , U 3 , function of r, θ, z, R, d. which is where U 1 , U 2 , U 3 , R, d are boundary conditions.

[0040] let r=r 0 =(RE 2+R) / 2, where RF2 is a constant, and r can be represented by R.

[0041] According to electromagnetic theory:

[0042]

[0043] That is, σ=Ψ(U 1 , U 2 , U 3 , I, R, d)

[0044] If U 1 , U 2 , U 3 , I takes a fixed value, then

[0045] σ a =Ψ a (R,d)

[0046] σ b =Ψ b (R,d)

[0047] σ c =Ψ c (R,d)

[0048] According to the above mathematical derivation, in the cylindrical coordinate system, it can be seen that the resistivity is related to the radius of the electrode. Therefore, the electrodes are designed in circular and arcuate shapes. Using the Vb programming tool, the calculation program is written, and the measured da...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com