Electrochromic device with single substrate structure

A technology of electrochromic devices and electrochromic layers, applied in the direction of color-changing fluorescent materials, instruments, chemical instruments and methods, can solve the problems of pollution, leakage, high cost, etc., and achieve simple production process, high color-changing efficiency, and fast response time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

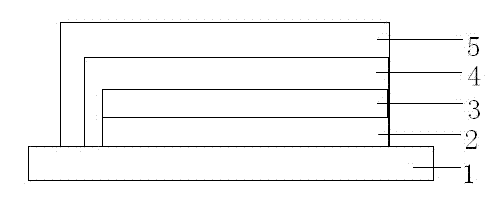

Image

Examples

Embodiment 1

[0015] The device uses conductive glass as the conductive substrate, and sequentially prepares nano-titanium dioxide layer, insulating reflection layer, and counter electrode layer by screen printing from bottom to top, and absorbs organic electrochromic materials on the nano-titanium dioxide layer as the electrochromic layer. The filling method fills the electrolyte as an ion-conducting layer. The nanometer titanium dioxide particle is 20nm, and the thickness of the titanium dioxide layer is about 5 μm. The insulating reflective layer is a nano-zirconia film with a thickness of about 5 μm. The electrolyte is a methoxypropionitrile solution of lithium perchlorate, and the counter electrode layer is a conductive film made of graphite and carbon black. In order to prevent the liquid electrolyte from leaking and volatilizing, the device is packaged with hot melt adhesive and a piece of ordinary glass. The test result of applying 1V voltage shows that the coloring time is 2.1s a...

Embodiment 2

[0017] The device uses conductive glass as the conductive substrate, and sequentially prepares nano-titanium dioxide layer, insulating reflection layer, and counter electrode layer by screen printing from bottom to top, and absorbs organic electrochromic materials on the nano-titanium dioxide layer as the electrochromic layer. The filling method fills the electrolyte as an ion-conducting layer. The nanometer titanium dioxide particle is 20nm, and the thickness of the titanium dioxide layer is about 8 μm. The insulating reflective layer is a nano-titanium dioxide film with a thickness of about 5 μm. The electrolyte is a solution of lithium trifluoromethanesulfonate in methoxypropionitrile. The counter electrode layer is a conductive film made of graphite and carbon black. In order to prevent the liquid electrolyte from leaking and volatilizing, the device is packaged with hot melt adhesive and a piece of ordinary glass. The test result of applying 1V voltage shows that the c...

Embodiment 3

[0019] The device uses conductive glass as the conductive substrate, and sequentially prepares a nano-titanium dioxide layer, an insulating reflection layer, and a counter electrode layer by screen printing from bottom to top, and adsorbs organic electrochromic materials on the nano-titanium dioxide layer as the electrochromic layer. The coating method fills the electrolyte as an ion-conducting layer. The nano titanium dioxide particles are 25nm, and the thickness of the titanium dioxide layer is about 8 μm. The insulating reflective layer is a zirconia film with a thickness of about 8 μm. The electrolyte is lithium perchlorate in acetonitrile. The counter electrode layer is a conductive film made of graphite and carbon black. In order to prevent the liquid electrolyte from leaking and volatilizing, the device is packaged with hot melt adhesive and a piece of ordinary glass. The test result of applying 1V voltage shows that the coloring time is 2.7s and the fading time is 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com