Method for separating shells and kernels in leftovers of manually-peeled pecans

A technology of leftovers and hickory nuts, which is applied in the field of separation of hand-peeled hickory nuts, can solve the problems of undiscovered hickory kernels leftovers, hickory kernels cannot be reused, and the price of hickory products is high, achieving separation Safe and reliable process, simple method and short separation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

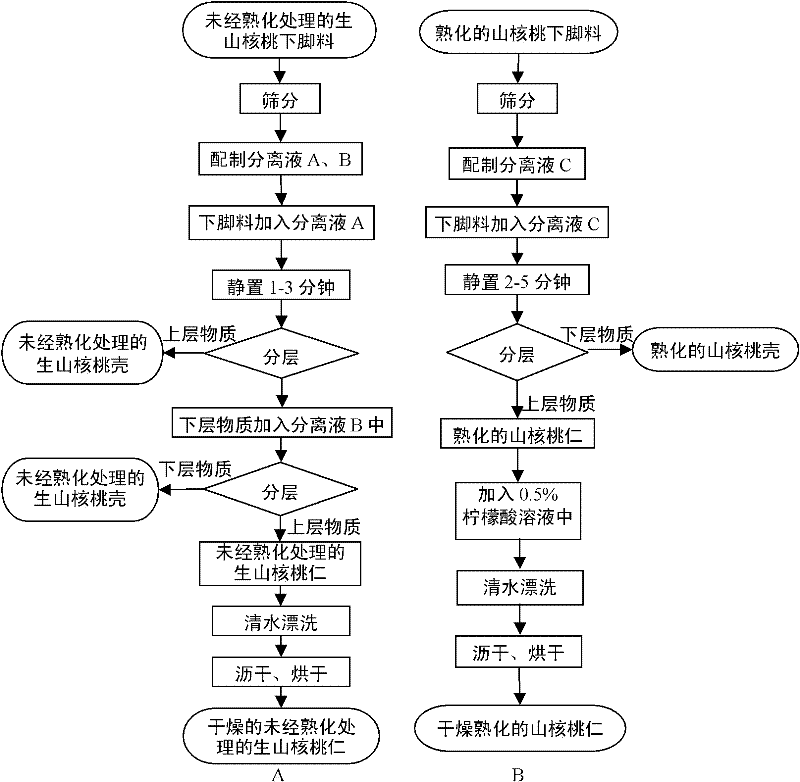

Method used

Image

Examples

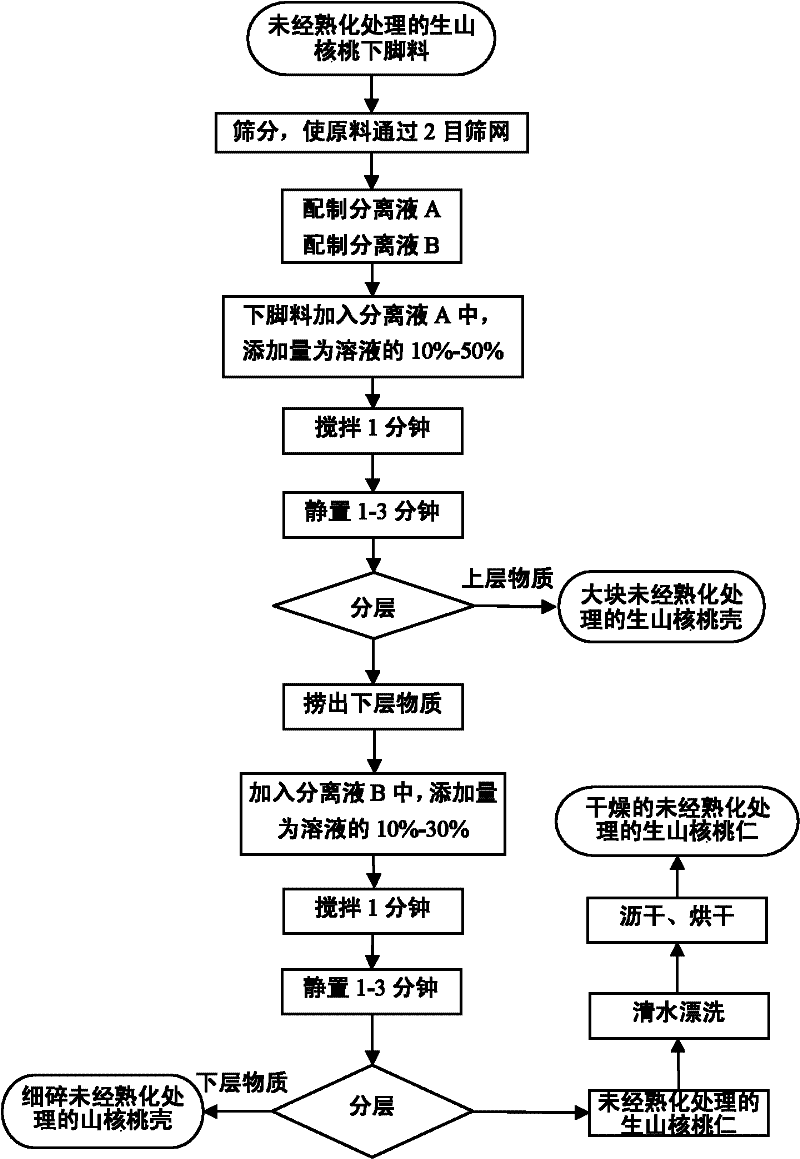

Embodiment 1

[0055] Embodiment 1: The process of isolating hickory kernels from unripe hickory leftovers produced by hand in Ningxia.

[0056] The reagents needed to prepare the solution are: salt NaCl, 95% edible alcohol C 2 h 5 Oh.

[0057] Instruments and equipment: sieving machine or sieve, pool or stainless steel bucket or plastic bucket, dense stainless steel wire mesh colander.

[0058] Operating procedure:

[0059] The first step: pretreatment of scraps

[0060] Sieve Ningguo raw hickory leftovers that have not been ripened, pass through a 2-mesh sieve, and take the thing under the sieve, so that the particle size of the unripe raw hickory is below 2 mesh.

[0061] The second step: separation solution preparation

[0062] When the temperature is 20°C, prepare alcohol C with a concentration of 15%-20% 2 h 5 OH solution, if preparing 100L solution, take 15.8-21L 95% alcohol C 2 h 5 OH, add water to 100L to complete the preparation of separation solution A;

[0063] Prepare ...

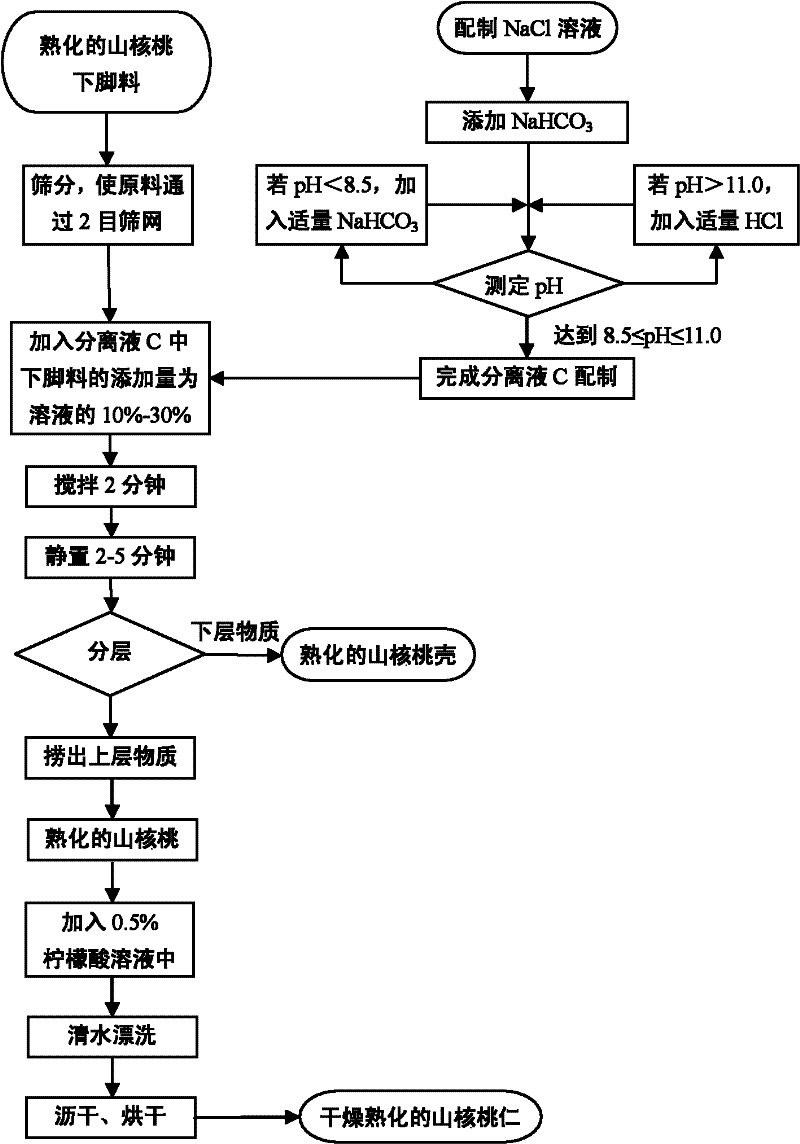

Embodiment 2

[0070] Embodiment 2: The process of separating hickory kernels from the leftovers of hickory nuts made by hand peeling and frying in Ningxia.

[0071] The reagents needed to prepare the solution are: salt NaCl, edible alkali NaHCO 3 , hydrochloric acid HCl, citric acid C 6 h 8 o 7 .

[0072] Instruments and equipment: screening machine or sieve, pool or stainless steel bucket or plastic bucket, dense stainless steel wire mesh colander

[0073] Operating procedure:

[0074] Step 1: Pretreatment of fried Ningguo hickory leftovers

[0075] Sieve the fried Ningguo hickory leftovers, pass through a 2-mesh sieve, and take the sieve for subsequent use, so that the particle size of the fried Ningguo hickory is below 2 mesh.

[0076] The second step: the preparation of separation solution C

[0077] When the temperature is 20°C, prepare a salt NaCl solution with a mass fraction of 8.75%. If a 100L solution is prepared, take 8750g of salt NaCl and set the volume to 100L; then add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com