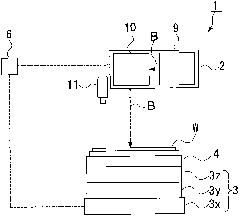

Laser processing device and laser processing method

A laser processing method and laser processing technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve problems such as cracks and divisions, and achieve stable processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

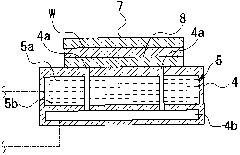

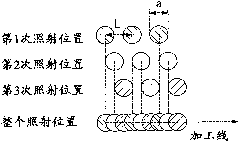

[0053] Next, examples at the time of actual processing will be specifically described based on the laser processing apparatus and the laser processing method according to the present invention.

[0054] In this example, a ceramic sintered body (thickness: 250 μm) was processed as an object to be processed with laser light having a wavelength of 355 nm using the laser processing apparatus of this embodiment. At this time, a polyimide resin film (thickness 0.1 mm) was bonded to the surface of the ceramic sintered body as a resin film with an acrylic adhesive, and an aluminum film (thickness 0.05 mm) was used as a metal film with a silicone adhesive. The film is glued to the back. The object to be processed in this state is attracted to the mounting jig.

[0055] The output of the laser is set to 1.3W, the repetition frequency H is set to 125kHz, and the beam point is measured. The result is that the beam diameter is 20μm, so the scanning speed S is set to 3750mm / sec, and the sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com