Adhesive tape

An adhesive tape and adhesive layer technology, applied in the direction of adhesives, film/sheet adhesives, non-polymer adhesive additives, etc. , adhesive composition exposure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

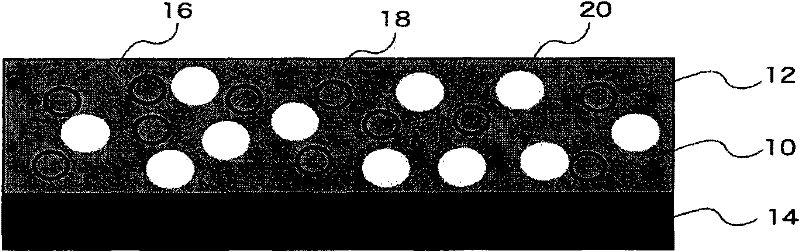

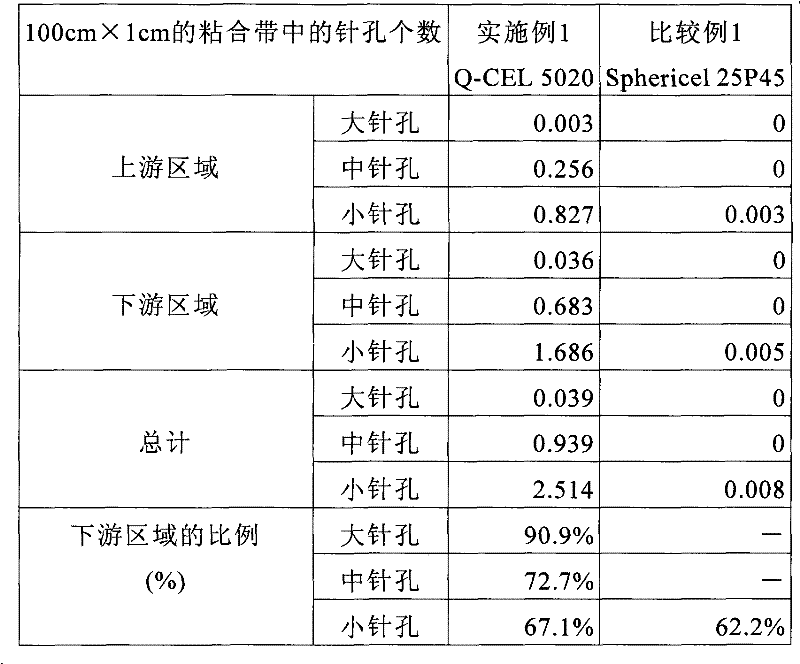

[0136] Into a mixture of 90 parts by weight of 2-ethylhexyl acrylate and 10 parts by weight of acrylic acid as monomer components, 0.05 parts by weight of the trade name "Irgacure 651" (manufactured by Ciba Specialty Chemicals) and the trade name " Irgacure 184 " (manufactured by Ciba Specialty Chemicals Co., Ltd.) 0.05 parts by weight as a photopolymerization initiator, then irradiated with ultraviolet rays until the viscosity (using a BH type viscometer, No. 5 rotor, measured at 10 rpm and a measurement temperature of 30° C.) was about 15 Pa·s, thereby making a partially polymerized composition (prepolymer). 0.08 parts by weight of 1,6-hexanediol diacrylate was added to 100 parts by weight of the prepolymer. Further, 5.5 parts by weight of a product name "Q-CEL 5020" (manufactured by Pottazu Baroteini Co., Ltd.) was added to the prepolymer as hollow glass microspheres. In addition, 1 part by weight of the trade name "Surflon S-393" (manufactured by Sei Chemical Co., Ltd.; a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com