Quenching method and quenching machine tool for single ring of ring chain

A quenching machine tool, circular chain technology, applied in quenching device, furnace type, furnace and other directions, can solve the problems of out of tolerance, substandard products, waste of energy, etc., to save energy, ensure quality and work reliability, avoid Out-of-size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

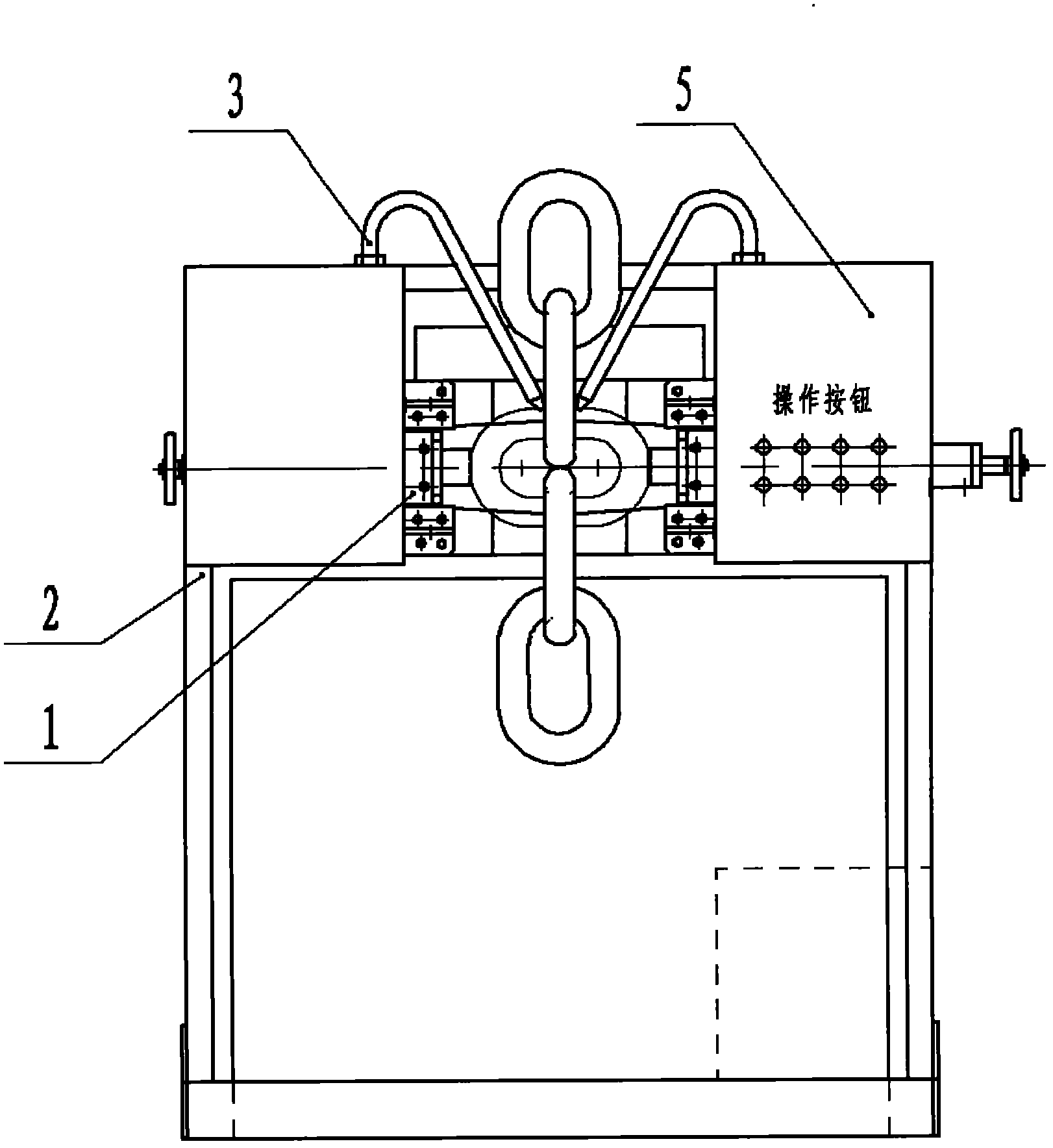

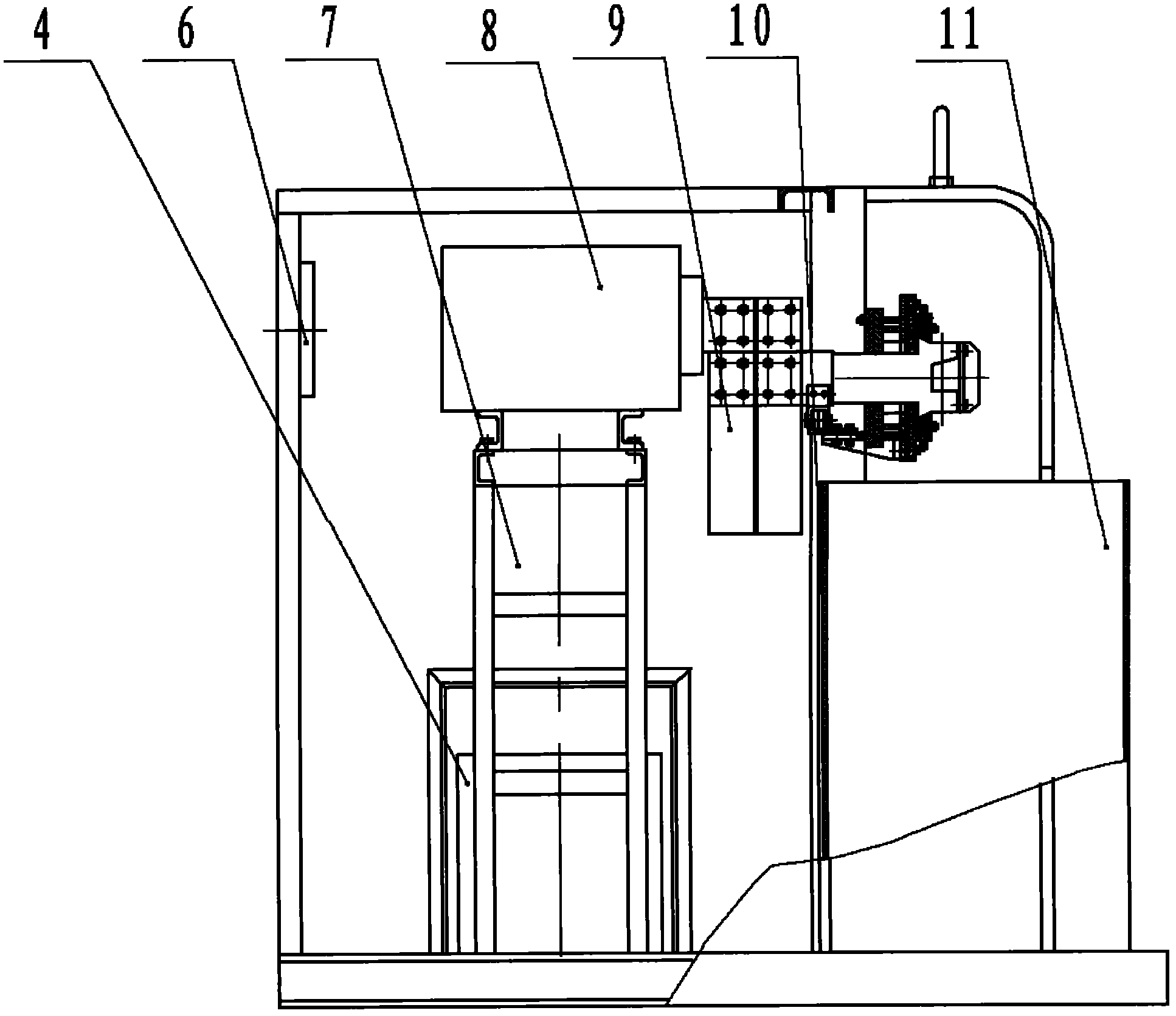

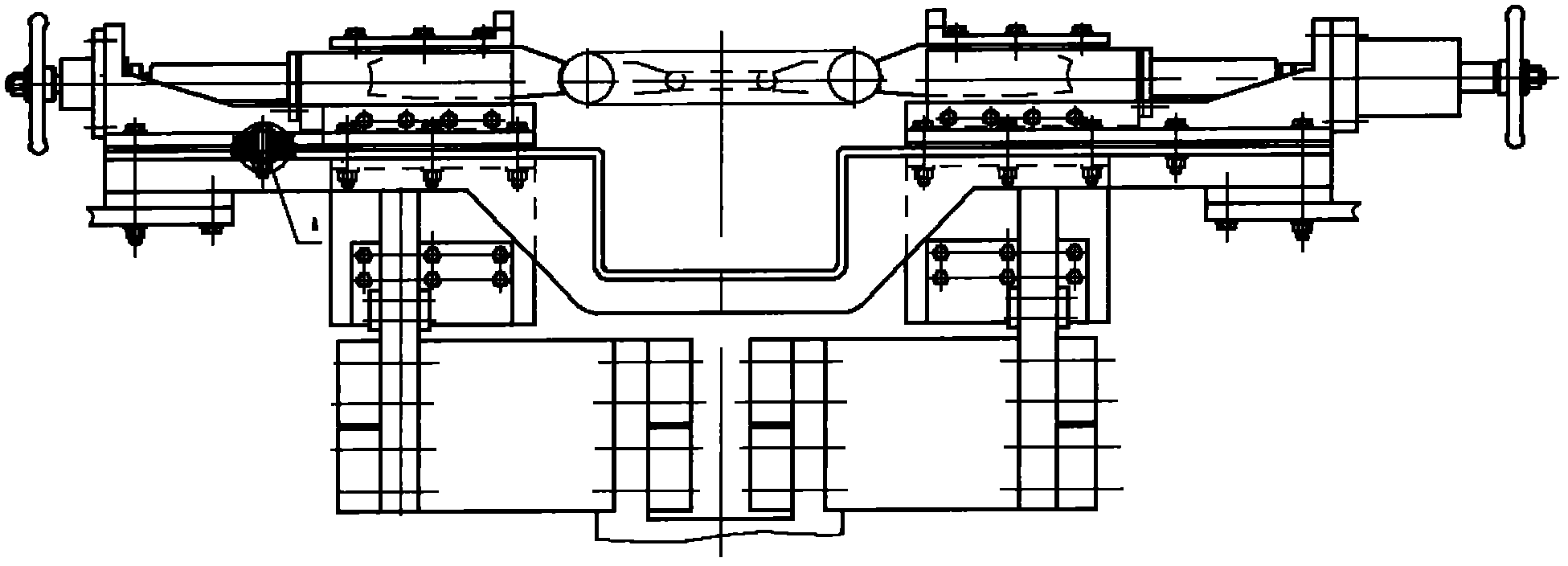

Embodiment Construction

[0014] The 34×126 mine is quenched with a single ring joined by a high-strength C-grade circular link. The top of the chain link is clamped by the electrode, and the single ring is clamped by the single ring quenching machine tool, and then energized for preheating, the heating voltage is 160V, the current is 60A, heated to 400-450°C, the secondary heating voltage is 175V, and the current is 80A; The thermometer measures the temperature. When the single ring is heated to the quenching temperature of 900°C±10°C, there is no need for heat preservation, the power is turned off and the water is cooled, and the quenching is completed.

[0015] Spot check the hardness of the single ring after quenching: the hardness of the two points on the top of the single ring is HRC47, HRC48; the hardness of the three points on the shoulder is HRC47.5, HRC47, HRC47, which is basically the same as that of the adjacent links on the chain. After single-ring tempering, the static tensile sample is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com