Method for recovering hexavalent chromium resources from chromium slag

A technology of hexavalent chromium and chromium slag, which is applied in the field of recycling hexavalent chromium resources, can solve the problems of wasting chromium resources, surrounding environmental pollution, etc., and achieve the effect of reducing the total residual chromium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

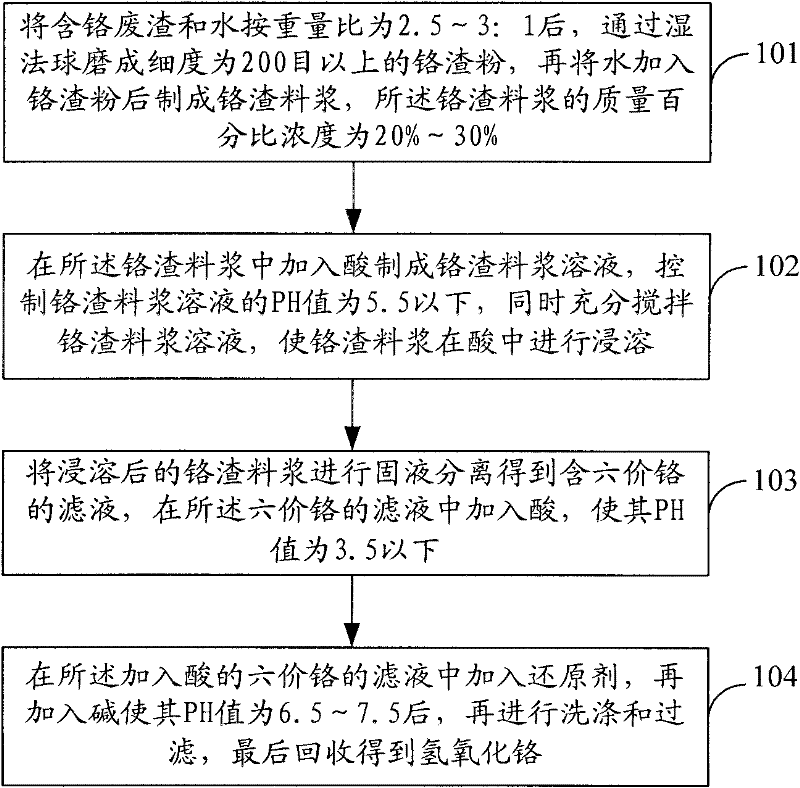

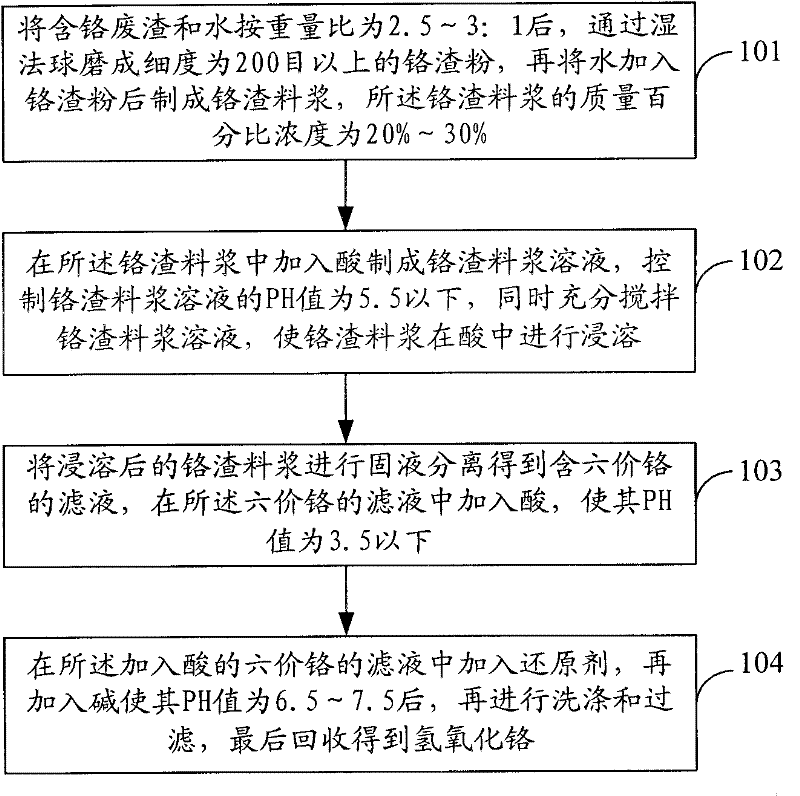

Method used

Image

Examples

Embodiment 1

[0033] The chromium-containing waste slag and water are wet-milled into chromium slag powder with a fineness of more than 200 mesh at a weight ratio of 2.5, and water is added to the chromium slag powder to make chromium slag slurry. The weight of the chromium slag slurry is Percentage concentration is 20%; Add hydrochloric acid in described chromium slag slurry and make chromium slag slurry solution, control the pH value of chromium slag slurry solution to be 4.5, fully stir chromium slag slurry solution simultaneously, make chromium slag slurry Dip in hydrochloric acid for 2 hours; carry out solid-liquid separation of the chromium slag slurry after leaching to obtain a filtrate containing hexavalent chromium, add hydrochloric acid to the filtrate of hexavalent chromium to make its pH value 3.5; A reducing agent is added to the filtrate of the hexavalent chromium added with acid, and then sodium carbonate or sodium hydroxide is added to make the pH value 6.5, followed by washi...

Embodiment 2

[0035] After the waste slag containing chromium and water are milled into chromium slag powder with a fineness of more than 200 mesh by wet ball milling at a weight ratio of 2.7:1, water is added to the chromium slag powder to make chromium slag slurry, and the chromium slag slurry is The weight percentage concentration is 25%; Add sulfuric acid in described chromium slag slurry and make chromium slag slurry solution, control the pH value of chromium slag slurry solution to be 5, fully stir chromium slag slurry solution simultaneously, make chromium slag The slurry is soaked in sulfuric acid for 3 hours; the solid-liquid separation of the chromium slag slurry after soaking is carried out to obtain a filtrate containing hexavalent chromium, and sulfuric acid is added to the filtrate of hexavalent chromium to make its pH value 3 Add a reducing agent to the filtrate of the hexavalent chromium added with acid, then add sodium carbonate or sodium hydroxide to make the pH value 7, th...

Embodiment 3

[0037] After the waste slag containing chromium and water are milled into chromium slag powder with a fineness of more than 200 mesh by wet ball milling at a weight ratio of 3:1, water is added to the chromium slag powder to make chromium slag slurry, and the chromium slag slurry is The weight percentage concentration is 30%; Add hydrochloric acid in described chromium slag slurry and make chromium slag slurry solution, control the pH value of chromium slag slurry solution to be 4, fully stir chromium slag slurry solution simultaneously, make chromium slag The slurry was soaked in hydrochloric acid for 5 hours; the chromium slag slurry after soaking was subjected to solid-liquid separation to obtain a filtrate containing hexavalent chromium, and hydrochloric acid was added to the filtrate of hexavalent chromium to make its pH value 3 Add a reducing agent to the filtrate of the hexavalent chromium added with acid, then add sodium carbonate or potassium hydroxide to make the pH v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com