Straight shaft plunger pump with limiting arc-shaped slide rail balance

A plunger pump and slide rail technology, which is applied in the field of limit arc slide rail swing plate straight axis plunger pump, can solve the problem of reducing the noise of the whole pump and the service life of the whole pump, increasing the overturning moment of the rotor and the swing plate, and affecting the operation of the rotor Stability and other issues to achieve the effect of reducing vibration and noise, overcoming lateral movement, unique structural features and functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

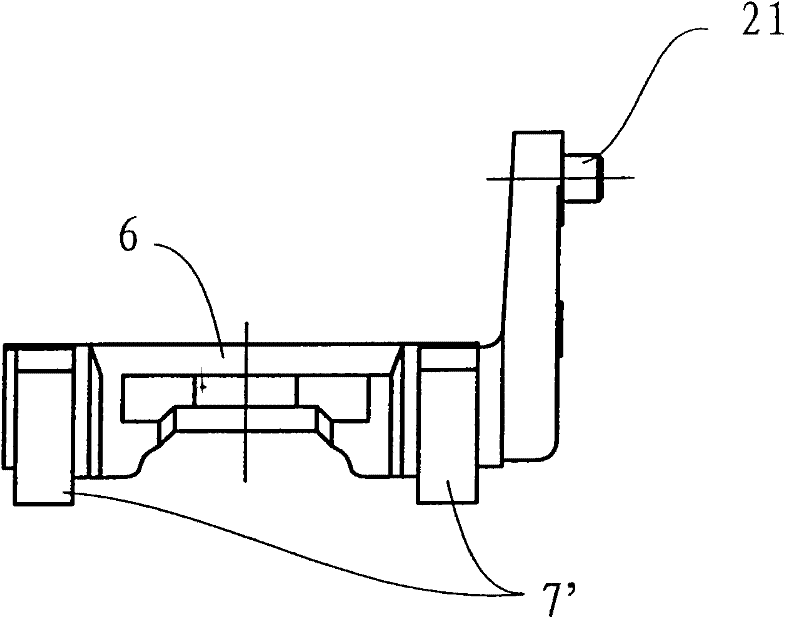

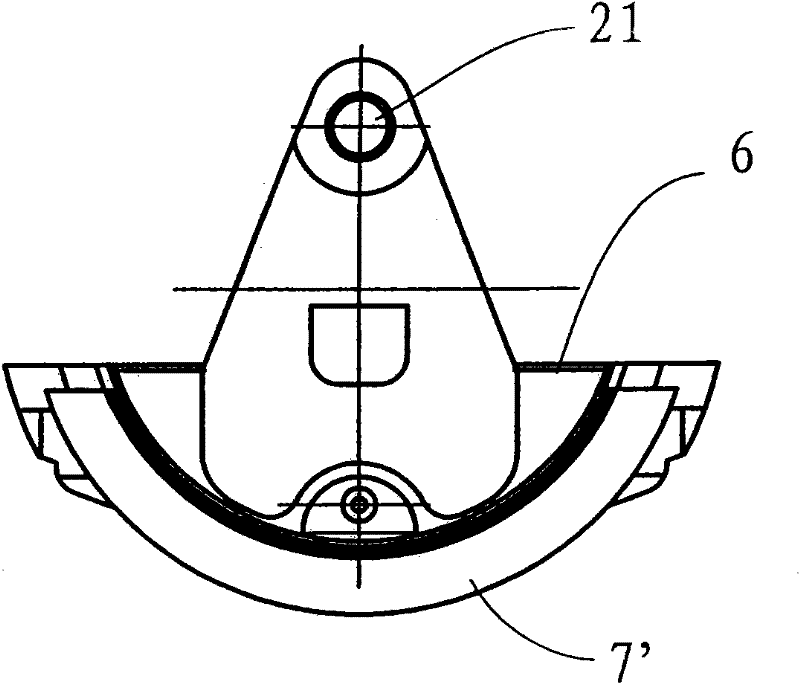

[0031] Figure 4Shown is the best embodiment of the present invention. In this embodiment, the upper surface of the lateral limit arc slide rail 170 is provided with an arc groove 171 along the arc direction, and the lateral limit slide rail 140 The upper surface is provided with a circular arc convex rib 141 that is slidingly matched with it; or the upper surface of the horizontal limiting arc slide rail is provided with an arc convex rib along the arc direction, and the horizontal limiting slideway is provided with a corresponding Slip fit arc groove.

[0032] The arc convex edge along the arc direction contains three meanings, one is a convex edge; second, the arc along the arc line refers to the arc line along the length direction of the arc slide rail, that is, the convex edge The length direction of the arc-shaped slide rail is consistent with the length direction of the arc-shaped slide rail, and the two do not intersect, and the angle is zero; thirdly, the top of the ...

Embodiment 2

[0037] Figure 5 Shown is a structural schematic view of another preferred embodiment of the limiting arc-shaped slide rail and the slideway on the wobble plate of the present invention. In this embodiment, the upper surface of the transverse limiting arc slide rail 170' is provided with a V-shaped groove 171' along the arc direction, and the transverse limiting slideway 140' is provided with a The V-shaped rib 141'; or the upper surface of the transverse limit arc slide rail is provided with a V-shaped rib along the arc direction, and the transverse limit slide is provided with a V-shaped concave groove.

[0038] This embodiment also has the various functional characteristics of Embodiment 1, and has better machining performance compared with Embodiment 1, because the circular arc groove or circular arc convex edge needs to be processed with a numerical control machine tool, and the circular V Grooves or V-shaped ribs can be completed with ordinary machine tools. It has an...

Embodiment 3

[0040] Figure 6 Shown is another embodiment of the limiting arc-shaped sliding rail and limiting arc-shaped chute of the present invention. In this embodiment, the upper surface of the transverse limiting arc-shaped sliding rail 170" is provided with The T-shaped groove 171" in the linear direction, and the T-shaped rib 141" that slides with it is provided on the lateral limit slideway 140"; or the upper surface of the transverse limit arc slide rail is provided with a T-shaped ribs in the arc direction, and T-shaped grooves slidingly matched with the transverse limiting slideway.

[0041] The advantage of this embodiment is that the lateral limit is strict, but there is no automatic centering feature, and the difficulty of processing is between the first and second embodiments.

[0042] In each of the above embodiments, the slide rail is a copper alloy slide rail, or a powder metallurgy oil-impregnated slide rail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com