Device and method for in situ measurement of energy distribution of focused laser faculae

A technology of laser spot and energy distribution, which can be applied to measurement devices, optical devices, and electrical radiation detectors for photometry. It can solve problems such as inability to measure and large errors, and achieve the effect of overcoming weaknesses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

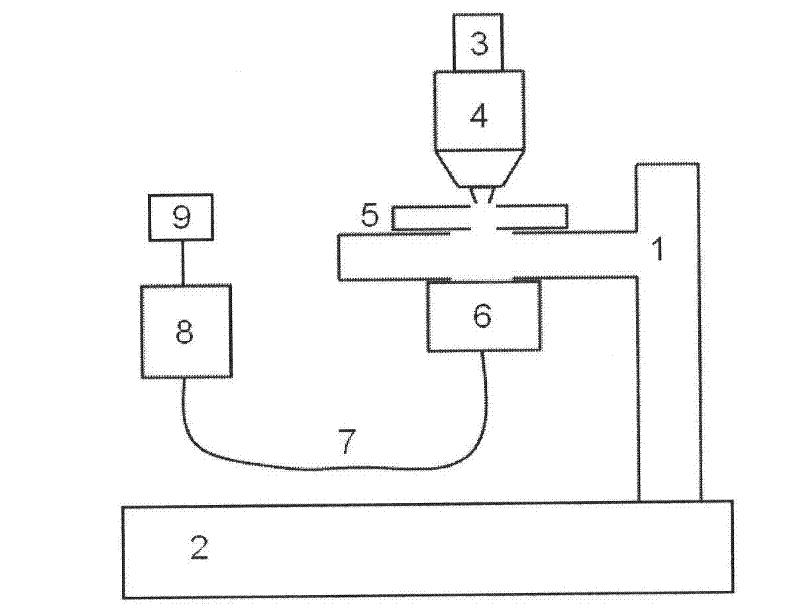

[0033] See attached figure 1 , make a laser spot energy distribution measuring device.

[0034] The small hole part of the present embodiment is made by the following steps,

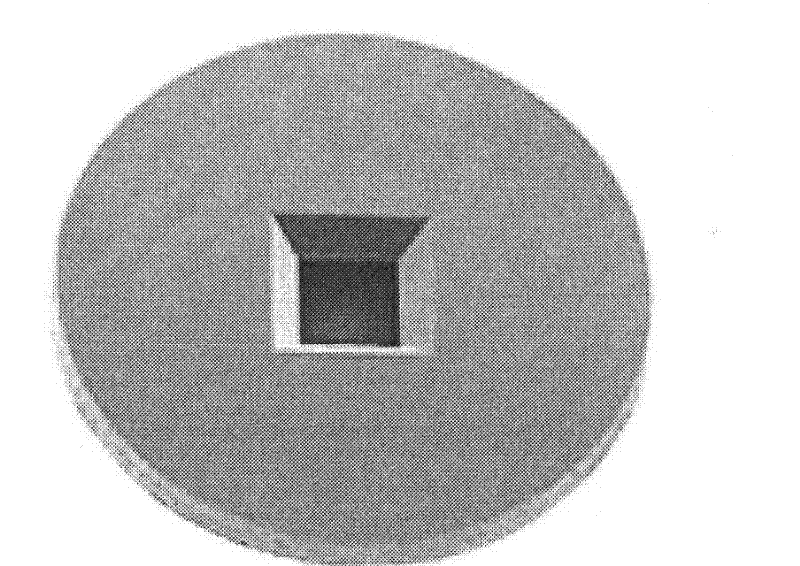

[0035] (1) Select a silicon wafer with a silicon nitride film window purchased on the market (see attached figure 2 ), the thickness of the silicon nitride film window is 200 nanometers; the shape of the window can be circular, rectangular or square;

[0036] (2) Evaporate a layer of gold film on the surface of the sample, and the thickness of the film can be implemented between 500-800 nanometers, as long as the silicon nitride film is opaque;

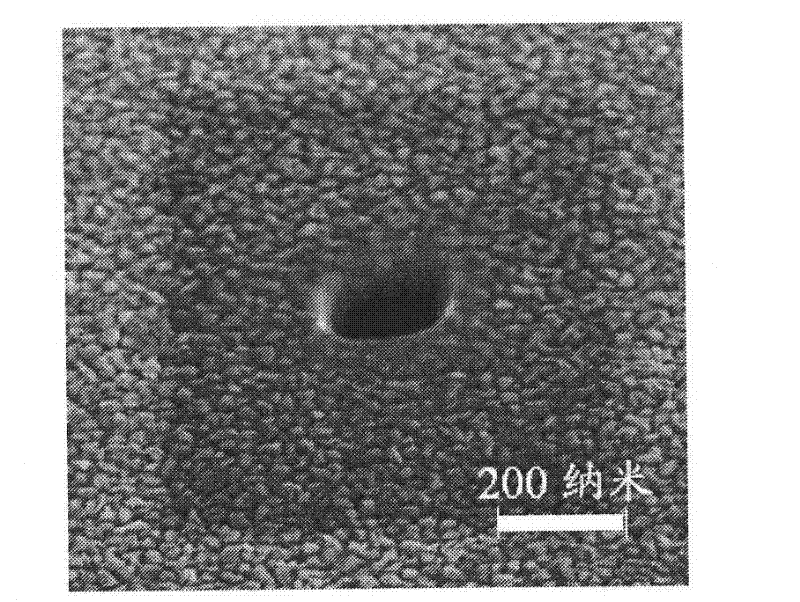

[0037] (3) Utilize focused ion beam technology to etch the required circular through hole (small hole) on the silicon nitride thin film of gold-plated film, the diameter of this circular through hole, for example all can be between 200-300 nanometers, carve through Gold-plated film and silicon nitride film (see attached image 3 and Figure 5 ).

[0038] ...

Embodiment 2

[0049] Follow the method and steps similar to those in Example 1.

[0050] See attached figure 1 , make a laser spot energy distribution measuring device.

[0051] The small hole part of this embodiment is made by the following steps:

[0052] (1) adopt the silicon wafer that has silicon nitride film groove (window) purchased on the market, wherein, the thickness of silicon nitride film groove is 200 nanometers;

[0053] (2) vapor-deposit a layer of gold film on the surface of the silicon wafer with the silicon nitride film groove (window), the thickness of the gold film is 500-800 nanometers, to ensure that the silicon nitride film is opaque; the groove is square;

[0054] (3) Etching a circular through hole with a diameter of 200-300 nanometers on the gold-plated silicon nitride film by using focused ion beam technology. The through hole is used to transmit a small amount of laser signal to prevent oversaturation of the detector; the diameter of the through hole directly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com