Solid forming method of active cell-hydrogel organ structure

A three-dimensional forming and hydrogel technology, applied in prosthetics, medical science, etc., can solve the problems of slow cell growth, death, and inability to quickly achieve vascularization, and achieve the effect of accelerating the process of vascularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

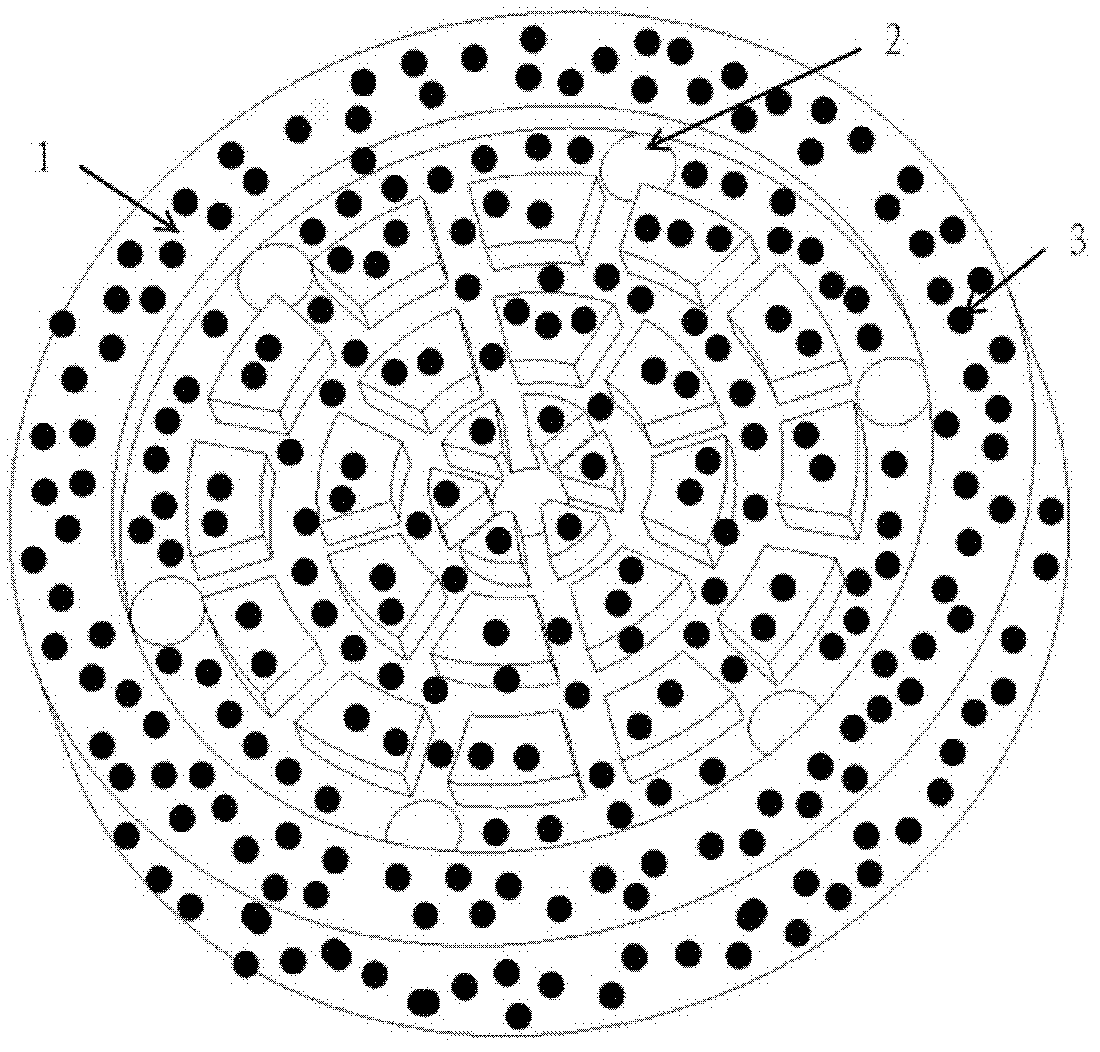

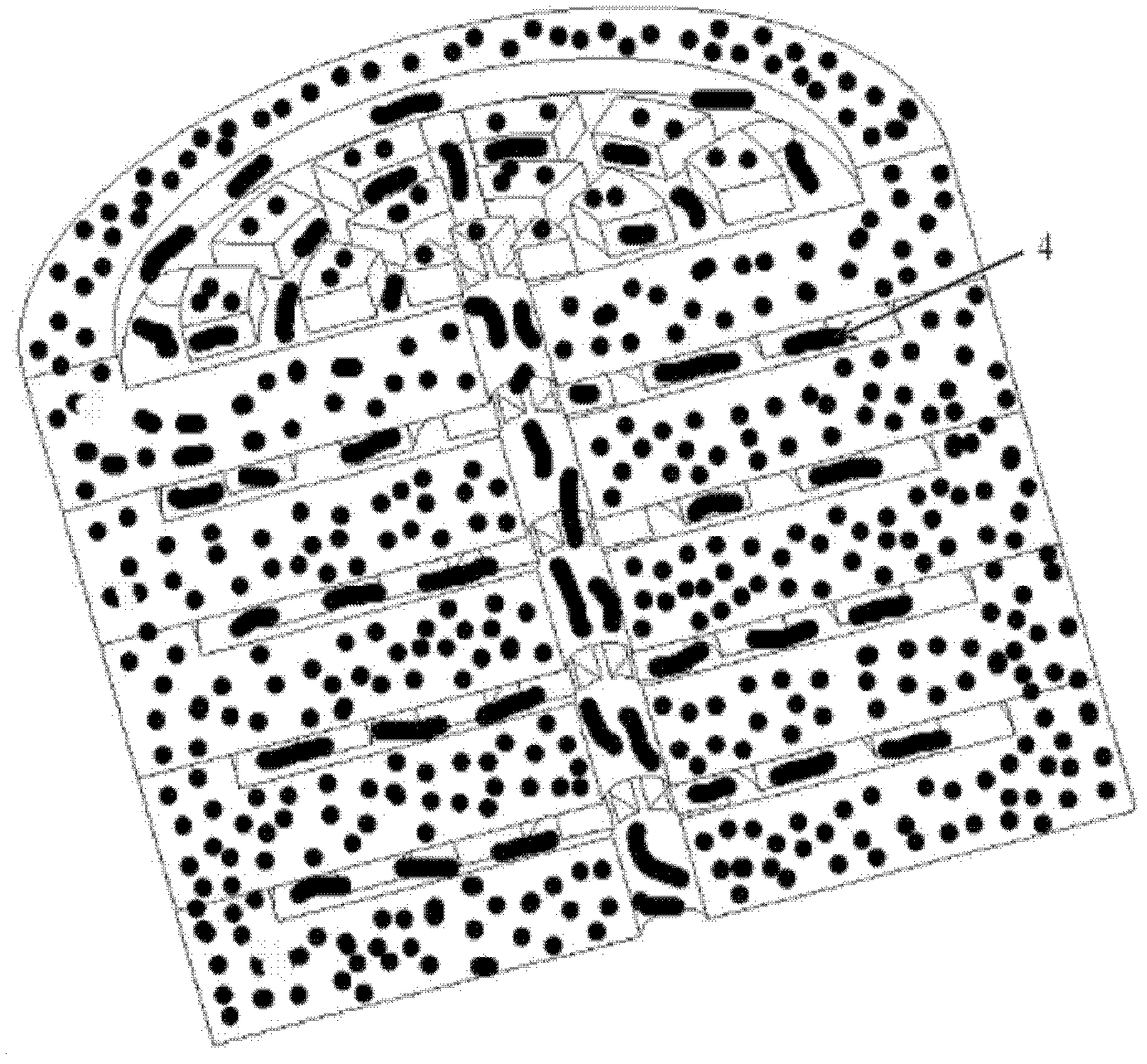

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0018] A three-dimensional forming method of an active cell-hydrogel organoid structure, comprising the following steps:

[0019] 1) According to the microstructural unit characteristics of liver, heart, kidney or lung, use 3D CAD software Pro / Engineer or UG to design a hydrogel unit model with bionic blood or culture fluid channel system, or use AutoCAD, CorelDraw and other software Design the photocuring mask of the bionic blood or culture fluid channel system. The hydrogel unit model channel system has a width of 50μm-1mm and a depth of 0.3-0.8mm.

[0020] 2) Export the designed hydrogel unit model in .STL format, use photocuring rapid prototyping or photolithography technology to manufacture the physical prototype of the hydrogel unit, and then use liquid medical silica gel or agarose with a mass fraction of 5%-10% The aqueous solution is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com