Method for manufacturing injectable water-swelling gingival retraction paste

A technology of water-absorbing swelling and manufacturing method, applied in the field of biomedical materials, can solve the problems of high price, unfavorable clinical wide application, etc., and achieve the effects of convenient operation, friendly production environment and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

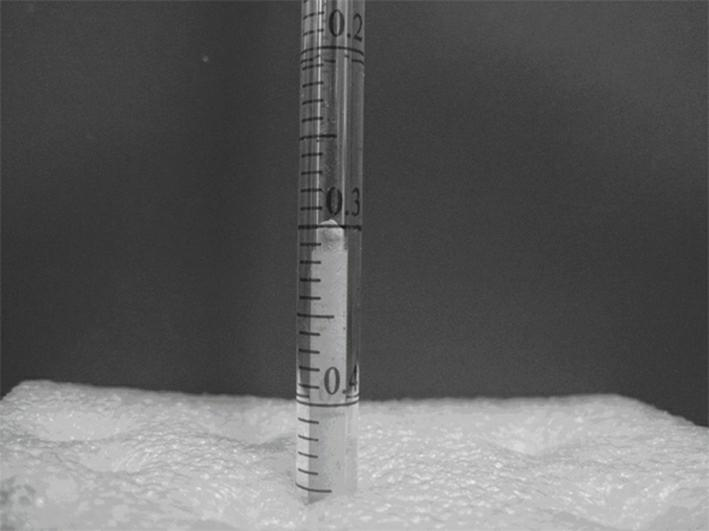

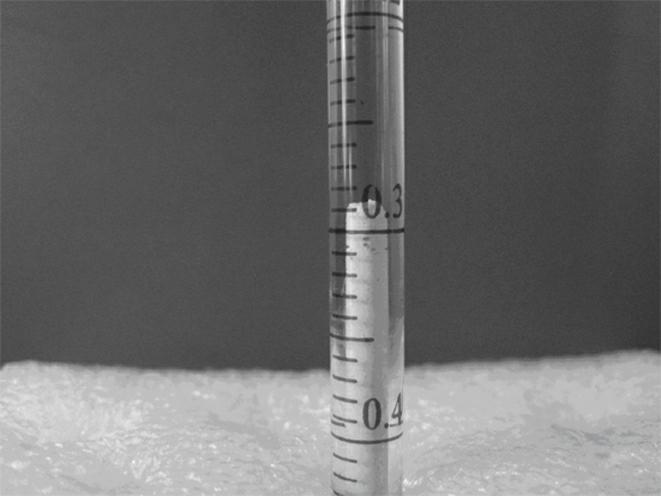

Embodiment 1

[0020] The preparation method of injectable water-absorbent swellable gingival retraction paste comprises the following steps: use an analytical electronic mass balance to measure 2 g of polyvinylpyrrolidone (PVP), measure 20 mL of 15% aluminum chloride solution in a graduated cylinder, mix the two , placed in a 70°C water bath to fully dissolve. After 30 minutes, slowly add 30g of kaolin measured by an analytical electronic mass balance, 2g of cross-linked polyvinylpyrrolidone (PVPP), put it into a digital constant temperature stirrer, stir well, the temperature is 70°C, the speed is 100r / s, stir The injectable water-absorbing swellable gingiva removal paste was obtained in 30 minutes. The appearance of the injectable water-absorbing swellable gingiva-removal paste was milky white, ooze-like semi-solid, and the specific structure and appearance, see Figure 5 ;Under a certain pressure, it can be molded by injection, has a certain viscoelasticity, can maintain the stability of...

Embodiment 2

[0024] Use an analytical electronic mass balance to measure 1 g of polyvinylpyrrolidone (PVP), and a measuring cylinder to measure 20 mL of 10% aluminum chloride solution. After mixing the two, place them in a water bath at 70 °C to fully dissolve them. After 30 minutes, slowly add 25g of kaolin measured by an analytical electronic mass balance, 2g of cross-linked polyvinylpyrrolidone (PVPP), put it into a digital constant temperature stirrer, stir well, the temperature is 70°C, the speed is 100r / s, stir 30min. Obtain an injectable water-swellable gingival retraction paste. Using method is the same as embodiment 1.

Embodiment 3

[0026] Measure 3g of polyvinylpyrrolidone (PVP) with an analytical electronic mass balance, and measure 20mL of 15% aluminum chloride solution with a graduated cylinder. After mixing the two, place them in a water bath at 70°C to fully dissolve them. After 30 minutes, slowly add 20g of kaolin measured by an analytical electronic mass balance, 3g of cross-linked polyvinylpyrrolidone (PVPP), put it into a digital constant temperature stirrer, stir well, the temperature is 70°C, the speed is 100r / s, stir 30min. Obtain an injectable water-swellable gingival retraction paste. Using method is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com