Technology for integrally forging valve with flange

A technology of integral forging and flanged valves, which is applied in the direction of valve devices, etc., can solve the problems of welding quality and the influence of the overall quality of valves, and achieve the effects of eliminating welding process, beautiful appearance and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is realized through the following technical solutions:

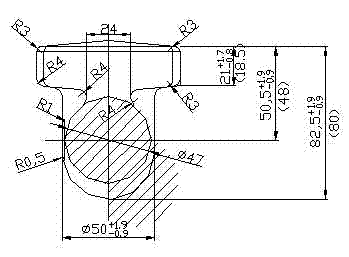

[0031] ①, the selection of blanks, in order to better forging and forming, we will develop the following forming process, and select the diameter of raw materials according to the cross section of the product Ф110 ~ 120mm;

[0032] ②. Medium frequency induction heating furnace GRT100×2000, medium frequency induction heating, heating time 50 seconds, material temperature 1100±50℃;

[0033] ③. Use the air hammer C41-750 to make the blank, the purpose is to remove the oxide skin on the surface of the blank;

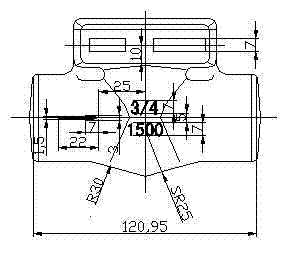

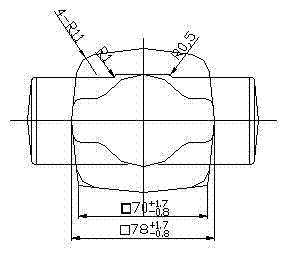

[0034] ④, use image 3 The shown pre-forging die is pre-forged on a 1600-ton hot die forging press, and the material temperature is ≥1050°C;

[0035] ⑤, use Figure 4 The final forging die shown is 1600 tons of hot die forging press for final forging, and the material temperature is ≥1000 °C;

[0036] ⑥. The trimming temperature is ≥950°C on a 315-ton hot die forging press;

[0037] ⑦. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com