Method and device for producing hydrogen by using chemical chain

A chemical chain and oxide technology, which is applied in the field of chemical chain hydrogen production method and its device, can solve the problems such as few reports, and achieve the effect of avoiding dilution, stable structure and good oxygen supply capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

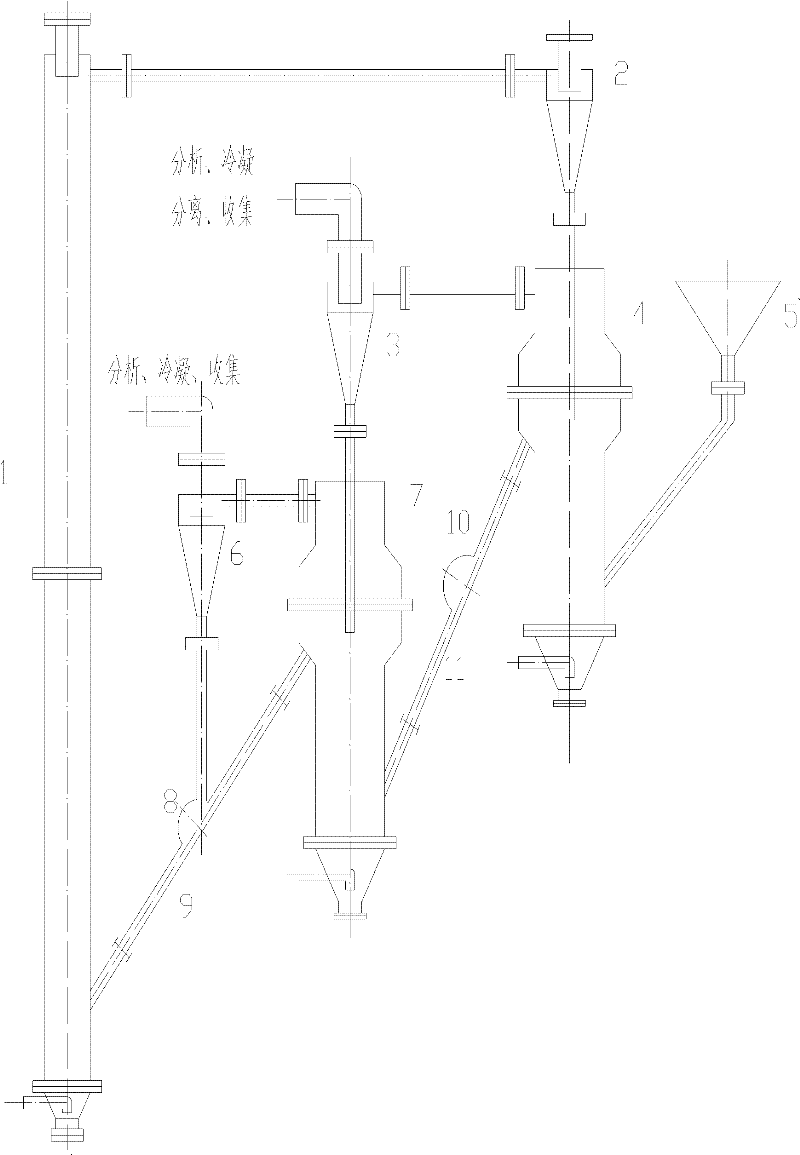

Method used

Image

Examples

Embodiment 1

[0029]Choose methane as the fuel gas; LaFeO3 as the oxygen carrier, the average particle size is 0.5mm; the inner diameter of the bubbling fluidized bed 4 and 7 reaction section is 300mm, the inner diameter of the expansion section is 500mm, and the height is 1200mm; the inner diameter of the entrained bed 1 is 100mm, the height 2000mm, the initial oxygen carrier addition is 30-40Kg, and fresh oxygen carrier can be added to the bubbling fluidized bed 4 at any time according to the reaction progress. The temperature of the bubbling fluidized bed 4 is stabilized between 880°C and 900°C, and the generated gas product passes through the cyclone separator and then enters the condensation device for separation and purification; the temperature of the bubbling fluidized bed 7 is stable at 800°C to 830°C Between ℃, the gas is discharged from the top and then enters the condensing device for separation and purification after passing through the cyclone separator; the temperature of the ...

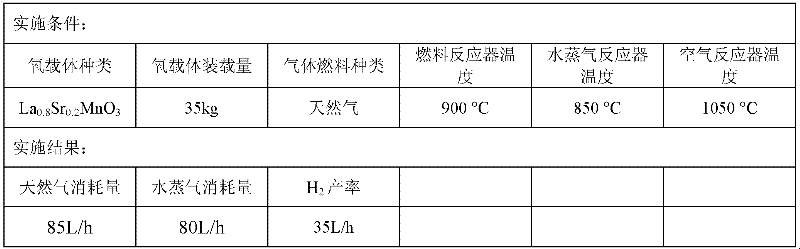

Embodiment 2

[0036] Since the operation process and operating device of each embodiment are the same, the specific implementation process is the same as that of Embodiment 1, and will not be repeated here. Only the implementation conditions and implementation results are listed in the table below.

[0037]

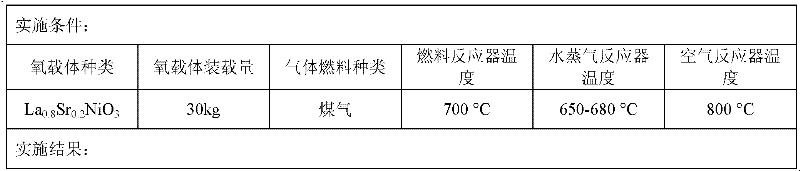

Embodiment 3

[0039] Since the operation process and operating device of each embodiment are the same, the specific implementation process is the same as that of Embodiment 1, and will not be repeated here. Only the implementation conditions and implementation results are listed in the table below.

[0040]

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com