Method for preparing organic/inorganic phase change energy storage composite material

A technology of inorganic phase transition and composite materials, applied in the field of material science and engineering, can solve the problems of high carrier cost, poor durability, inappropriate phase transition temperature, etc., and achieves simple preparation process, high stability and good practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

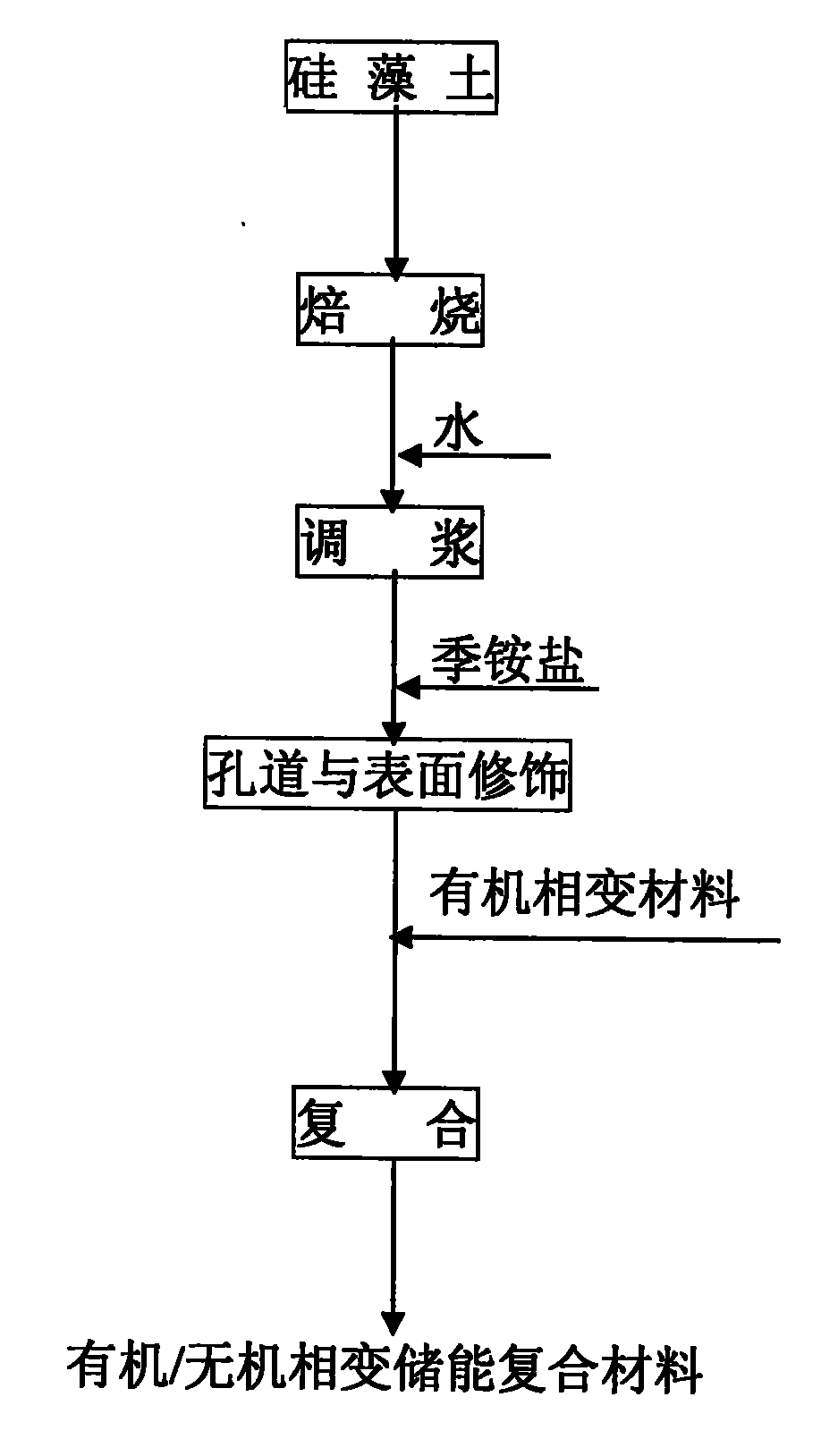

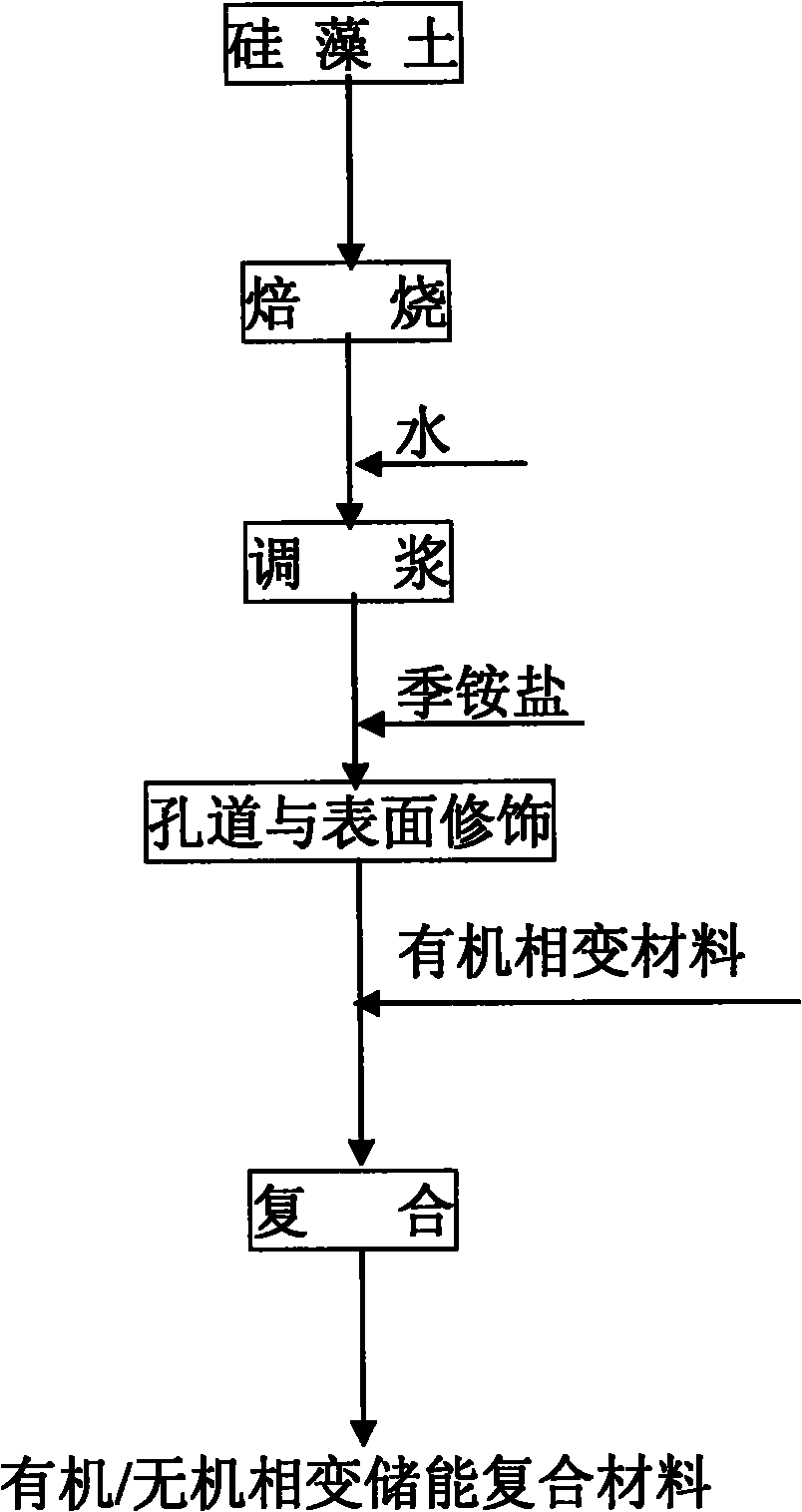

Method used

Image

Examples

Embodiment 1

[0023] Take 1000g of dry diatomite and roast it in a muffle furnace at 350°C for 3h; after cooling to room temperature, add 4000mL of water to make a slurry in a temperature-controllable reaction tank, then add 17.5g of polydimethyldiallylammonium chloride (PDMDAAC), stirred and reacted at 80°C for 2h, then filtered and dried at 105°C to obtain diatomite with pores and surface modification; mix this modified diatomite with 1500g organic phase change compound (1400g stearin N-butyl stearate + 100g methyl stearate) were placed in a temperature-controllable reaction tank, stirred and reacted at 95°C for 2 hours, and an organic / inorganic phase change energy storage composite material was obtained.

Embodiment 2

[0025] Take 1000g of dry diatomite and roast it in a muffle furnace at 350°C for 3h; after cooling to room temperature, add 4000mL of water to make a slurry in a temperature-controllable reaction tank, then add 17.5g of polydimethyldiallylammonium chloride (PDMDAAC), stirred and reacted at 80°C for 2h, filtered, and dried at 105°C to obtain pore and surface modified diatomite; place the modified diatomite and 1500g organic phase change material paraffin in a temperature-controlled Stirring and reacting at 95° C. for 2 hours in a reaction tank to obtain an organic / inorganic phase change energy storage composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com