Inorganic solidifying system for controlling bottom water coning in fracture-cavity karst reservoir, and injection method thereof

A carbonate reservoir, inorganic solidification technology, applied in the direction of chemical instruments and methods, production fluid, earth drilling and production, etc., can solve the problem that the partition fluid is difficult to adapt, and achieve the effect of changing the flow direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1: The composition of the inorganic solidification system is: superfine cement 25.46% (particle diameter is 10~100 μm, density is 2.8~3.2g / cm 3 ), density regulator 19.94%, reinforcing agent 2.97%, suspension dispersant 0.51%, drag reducer 0.38%, retarder 0.13%, skeleton bridging agent 0.21%, the rest is water, and the sum of each component is 100%, Stir evenly to form a density of 1.061g / cm 3 The system has an initial setting time of 5.5h and a compressive strength of 1.5MPa at 130°C.

Embodiment 2

[0011] Embodiment 2: The composition of the inorganic solidification system is: superfine cement 26.47% (particle diameter is 10~100 μ m, density is 2.8~3.2g / cm 3 ), density regulator 17.64%, reinforcing agent 2.21%, suspension dispersant 0.53%, drag reducer 0.40%, retarder 0.13%, skeleton bridging agent 0.22%, the rest is water, and the sum of each component is 100%, Stir evenly to form a density of 1.078g / cm 3 The system has an initial setting time of 7.0h and a compressive strength of 2.2MPa at 130°C.

Embodiment 3

[0012] Embodiment 3: The composition of the inorganic solidification system is: superfine cement 27.81% (particle diameter is 10~100 μm, density is 2.8~3.2g / cm 3 ), density regulator 17.12%, reinforcing agent 3.00%, suspension dispersant 0.51%, drag reducer 0.39%, retarder 0.13%, skeleton bridging agent 0.21%, the rest is water, the sum of each component is 100%, Stir evenly to form a density of 1.100g / cm 3 The system has an initial setting time of 6.0h and a compressive strength of 3.0MPa at 130°C.

[0013] On-site application:

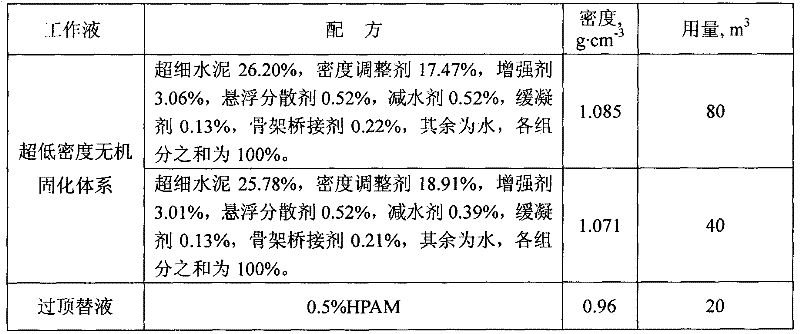

[0014] For the existing A test well, see Table 1 for its basic conditions and Table 2 for its working fluid conditions.

[0015] Table 1 Basic conditions of test wells

[0016] Happening

Well A

Production date

April 1999

Production layer

02yj; C1k

Reservoir section / (m)

5250~5540

[0017] Perforated section / (m)

5260~5540

Fracture-vuggy carbonate rock

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com