Low-elasticity microspheres for flood control and composite flood control system and flood control method containing them

A technology of elastic microspheres and controlled flooding, which is applied in chemical instruments and methods, drilling compositions, and production fluids. The effect of adjusting the flooding effect, increasing the swept volume, and improving the temperature and salt tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

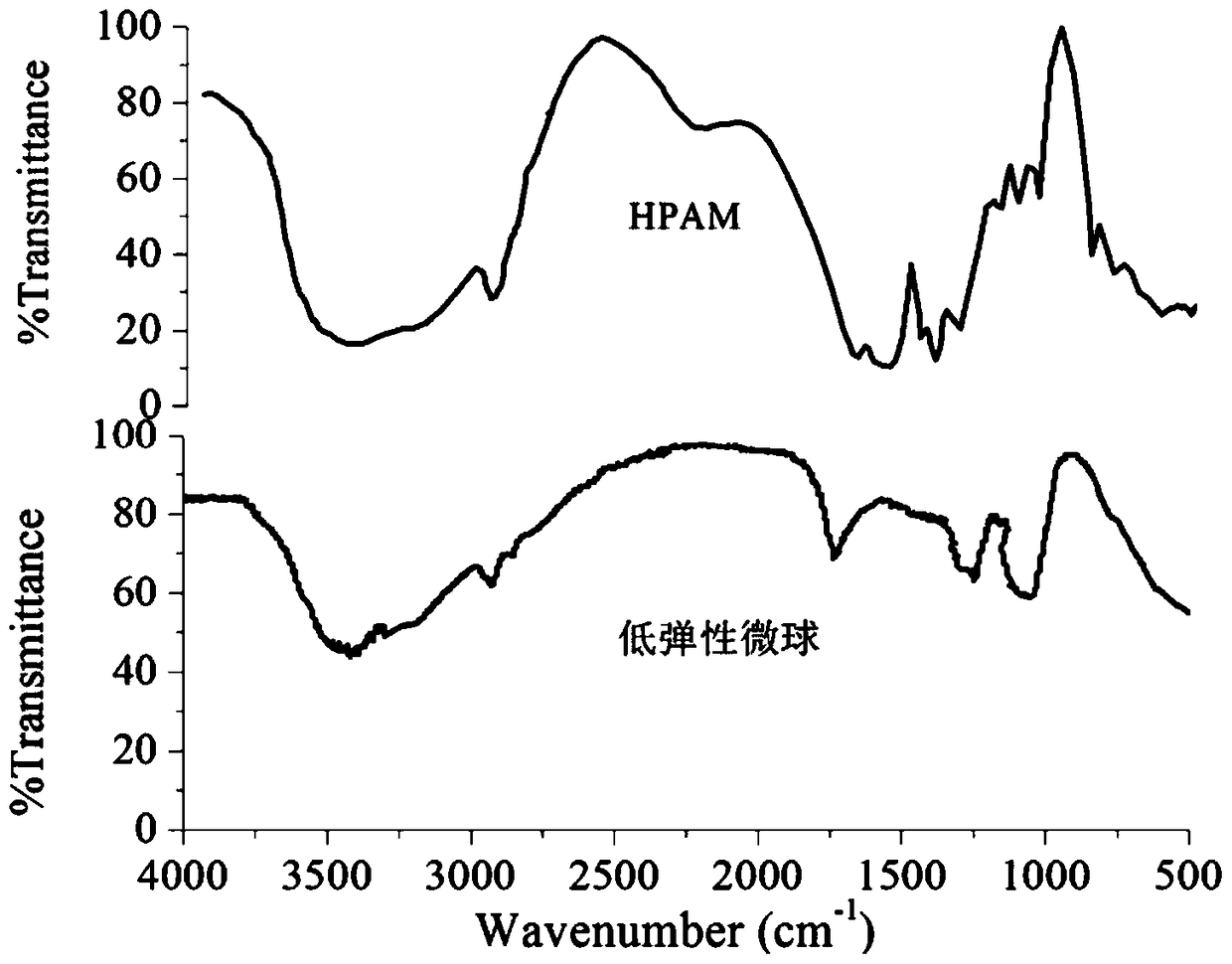

[0055] This embodiment provides a kind of low-elastic microspheres for regulating and driving, which is prepared by the following method:

[0056] Add 60mL of kerosene and 0.6g of dispersant SP-60 into a four-necked reaction flask equipped with an electric stirrer, reflux condenser, thermometer and nitrogen conduit, stir until the dispersant is completely dissolved, and then drip it with a constant liquid funnel under nitrogen protection. Add mixed solution 20g (this mixed solution is made of 6g acrylamide, 0.2g 2-acrylamide-2-methylpropanesulfonic acid, 0.0006g N, N'-methylenebisacrylamide, 0.254g concentration is 15wt% hydrogen Sodium oxide solution, 0.34g concentration is the ammonium chloride solution of 15wt%, 0.005g polyethylene glycol and distilled water surplus composition), simultaneously with the speed stirring of 500rpm, after dropping, add dropwise 1.0g concentration is 15wt% over Ammonium sulfate solution, at the same time using a water bath to gradually raise the...

Embodiment 2

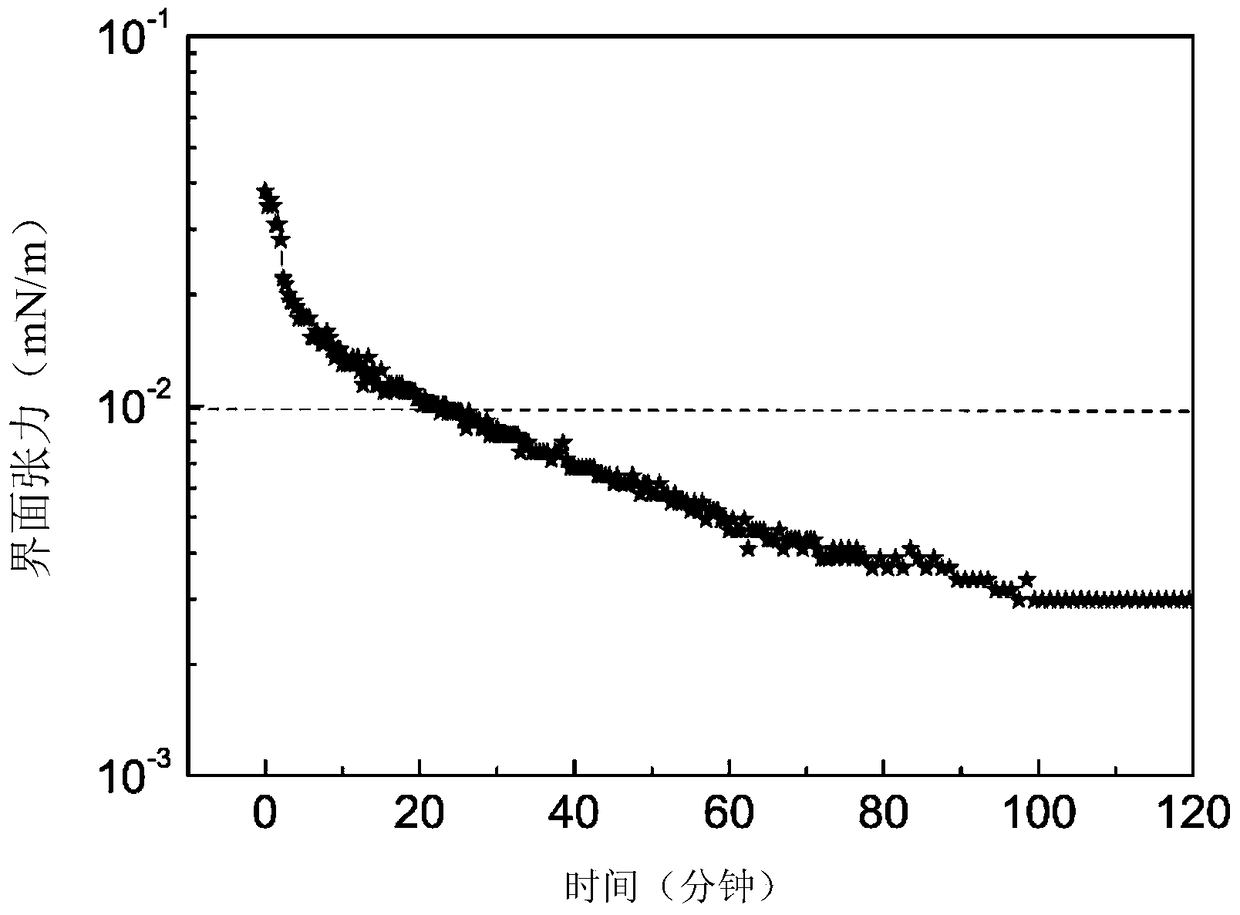

[0063] This embodiment provides a heterogeneous composite flood control system containing the low-elasticity microspheres prepared in Example 1, based on the total weight of the heterogeneous composite flood control system, it includes: implementation The low elastic microsphere 0.1% that example 1 prepares, petroleum sulfonate surfactant (PS) 0.4%, partially hydrolyzed polyacrylamide (HPAM) 0.1% and water (as dosing) balance, the weight percent of each component The sum is 100%; wherein, the petroleum sulfonate surfactant is petroleum sulfonate surfactant BHS-01 (developed by Dagang Oilfield Oil Production Technology Research Institute), its solid content ≥ 35%, lightning ≥ 60 ° C, The pH value (0.3wt% aqueous solution) is 7-9; the molecular weight of the partially hydrolyzed polyacrylamide is 27.4 million, and the degree of hydrolysis is 23.8%; the water is formation water and / or treated oilfield reinjection water.

[0064] The heterogeneous composite flood control system is...

Embodiment 3

[0066] This example provides how the low-elastic microspheres prepared in Example 1 pass through the glass etching model. The deformation and passage of the low elastic microsphere in the pore throat in the model is shown in Figure 4a , Figure 4b with Figure 4c . When the particle size of the microsphere is larger than the pore throat, under the action of a sufficiently large pressure difference, the pore throat is squeezed to lose water and undergo elastic deformation. During this process, the low-elasticity microsphere can carry the film-like residual oil on the surface of the pore throat After passing through the pore throats, the extrusion and stretching effects from the pore throats disappear, and the low-elastic microspheres absorb water again and return to their original size. During the process of shape restoration, the low-elastic microspheres expand toward the normal direction, and cannot be driven out before reaching the The "amoeba" characteristics of low ela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com