Combination pump of mechanical turbine

A combined pump and turbine technology, used in mechanical equipment, liquid variable capacity machinery, pumps, etc., can solve the problems of unstable operation, low power, high noise, etc., to ensure operating life, low noise and vibration, and noise and vibration. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

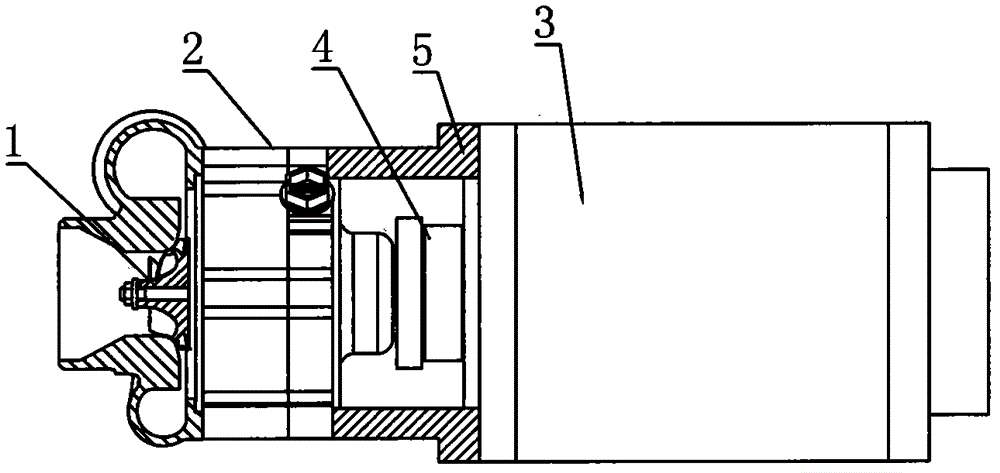

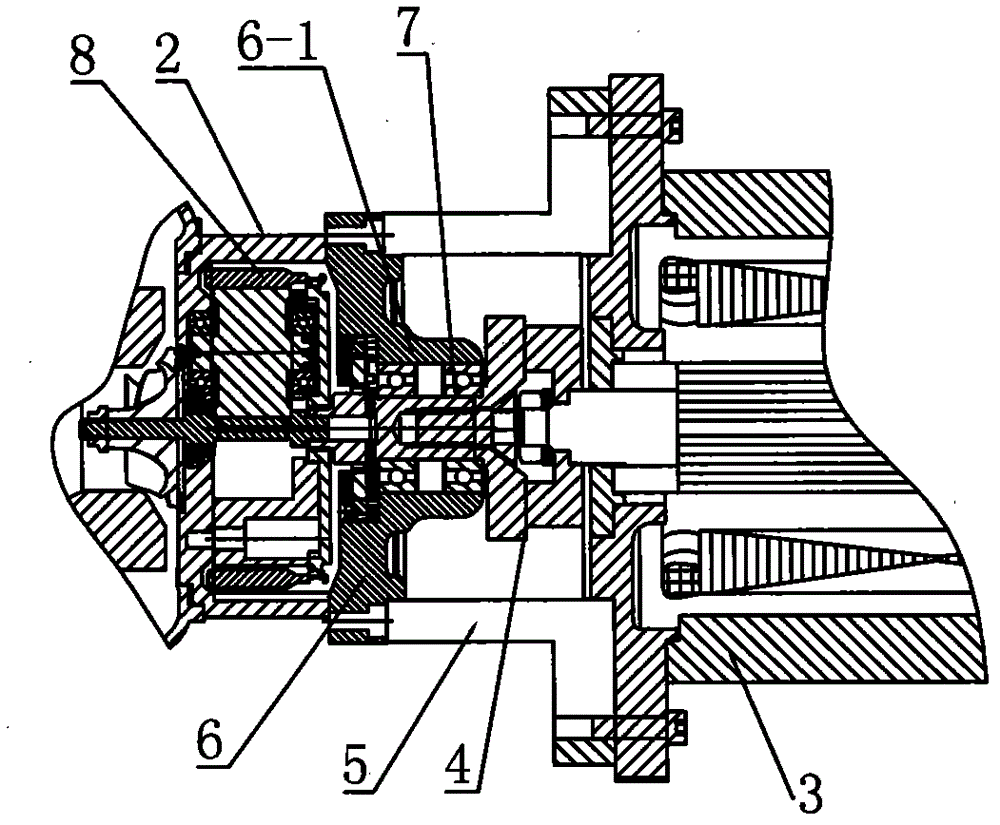

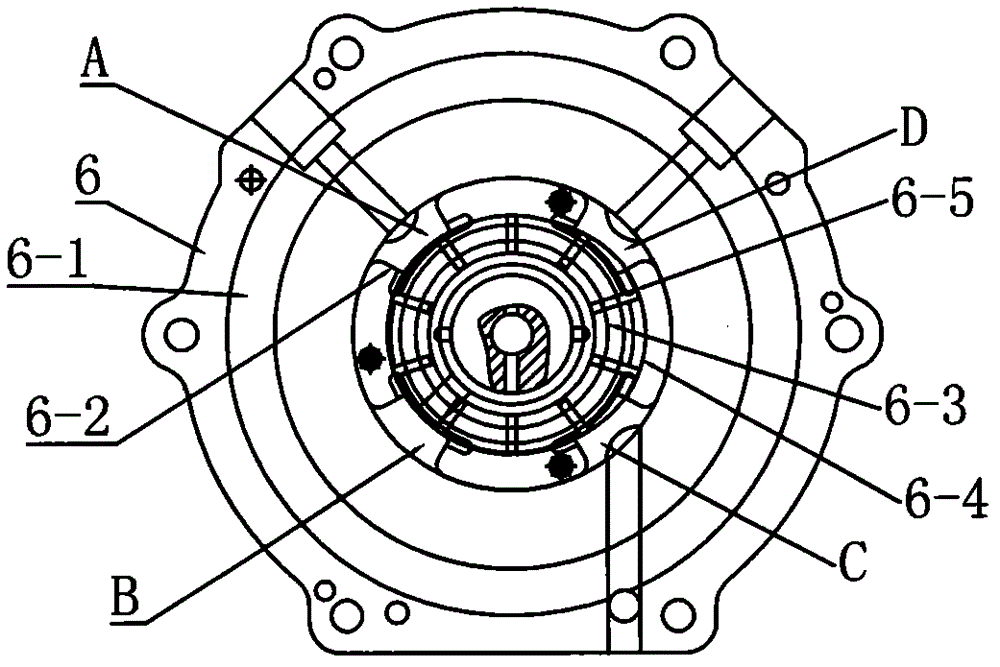

[0020] Such as Figure 1 ~ Figure 3 Shown, a kind of mechanical turbine combination pump of the present invention, it comprises turbo air compressor assembly 1, speed increaser 2, high-speed motor 3 and controller, turbine compressor air assembly 1 is connected on the speed increaser 2, motor 3 and speed increaser 2 The elastic coupling 4 is used for coaxial direct connection, and the controller is connected to the motor through the signal line. The end of the motor is provided with a ring-shaped support 5, and the shaft coupling 4 is arranged in the ring-shaped support 5, and the other end of the ring-shaped support 5 is screwed to the end surface of the speed increaser 2. In this embodiment, the mechanical turbine combined pump is applied to the turbo compressor for new energy fuel cells, using a 5.5KW high-speed brushless DC motor (rotating speed 15000RPM), the transmission ratio of the speed increaser is 12.67:1, and the turbine rotating speed reaches 190000RPM, which can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com