Pneumatic primary level graded low-pollution combustion chamber

A combustor, low-pollution technology, applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of inability to meet the low pollution requirements of the engine, high CO and UHC emissions, uneven local equivalence ratio, etc., and achieve simplified structure , low pollution emissions, efficient and stable work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

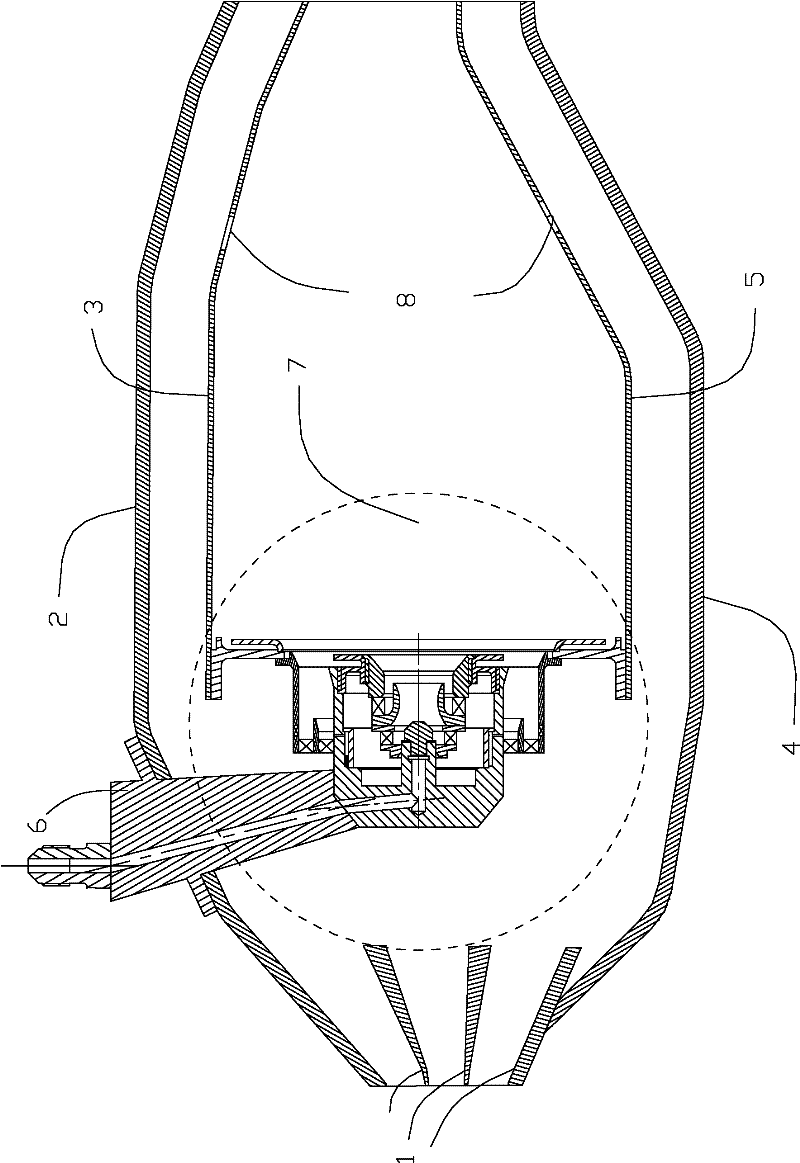

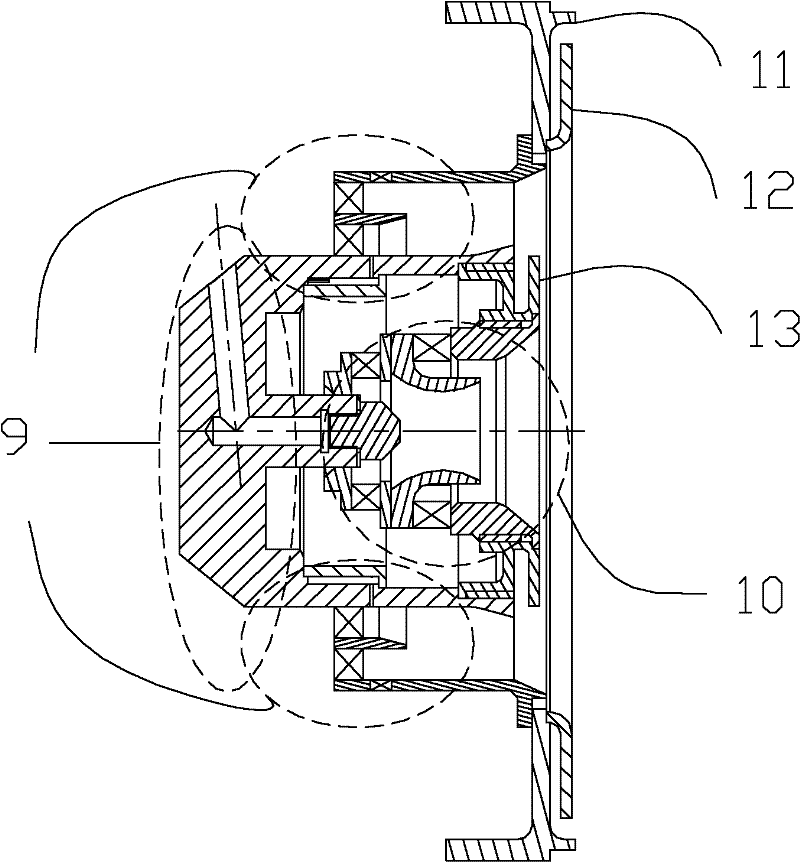

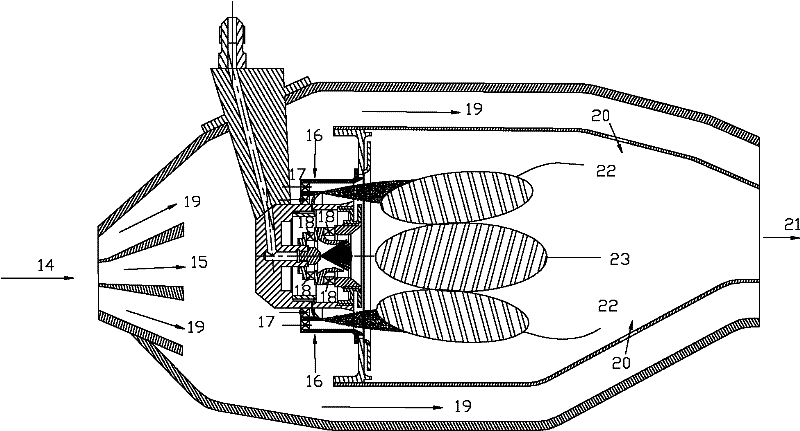

[0025] like figure 1 and figure 2 As shown, the present invention adopts a staged combustion method, and the amount of combustion gas is all supplied by the pre-combustion stage 10 and the main combustion stage 9. The premixed pre-evaporative combustion organization mode of radial injection fuel supply. The combustion chamber is mainly composed of a split diffuser 1, a casing outside the combustion chamber 2, a casing inside the combustion chamber 4, a fuel nozzle rod 6, a flame cylinder head 7, an outer wall 3 of the flame cylinder and an inner wall 5 of the flame cylinder. The flame tube head 7 is mainly composed of a pre-combustion stage 10, a main combustion stage 9, an isolation section 13, a head splash plate 12 and a head end wall 11. The fuel nozzle rod 6 is connected with the casing 2 outside the combustion chamber. The head splash plate 12 is welded to the head end wall 11, the head end wall 11 is connected to the outer wall 3 of the flame tube and the inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com