Battery management system

A battery management system and battery technology, applied in battery circuit devices, current collectors, electric vehicles, etc., can solve problems such as unbalanced charge and discharge, shorten the service life of series-connected battery packs, affect battery balance, etc., and prevent sharp fluctuations in voltage. , The effect of improving the charge-discharge characteristic curve and improving the use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Implementation of the present invention will be further described below in conjunction with accompanying drawing:

[0046] The invention is a battery management system for series battery packs.

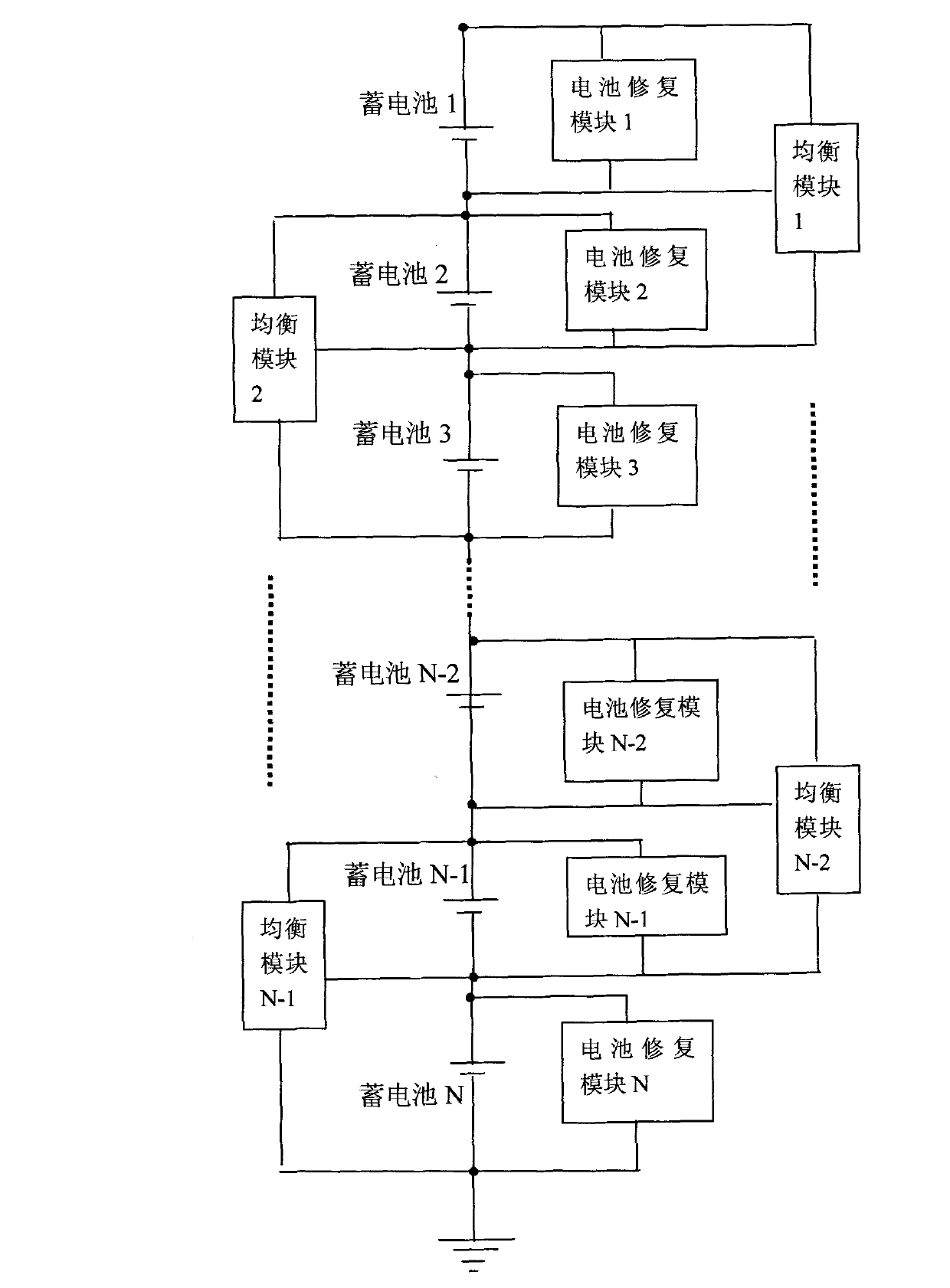

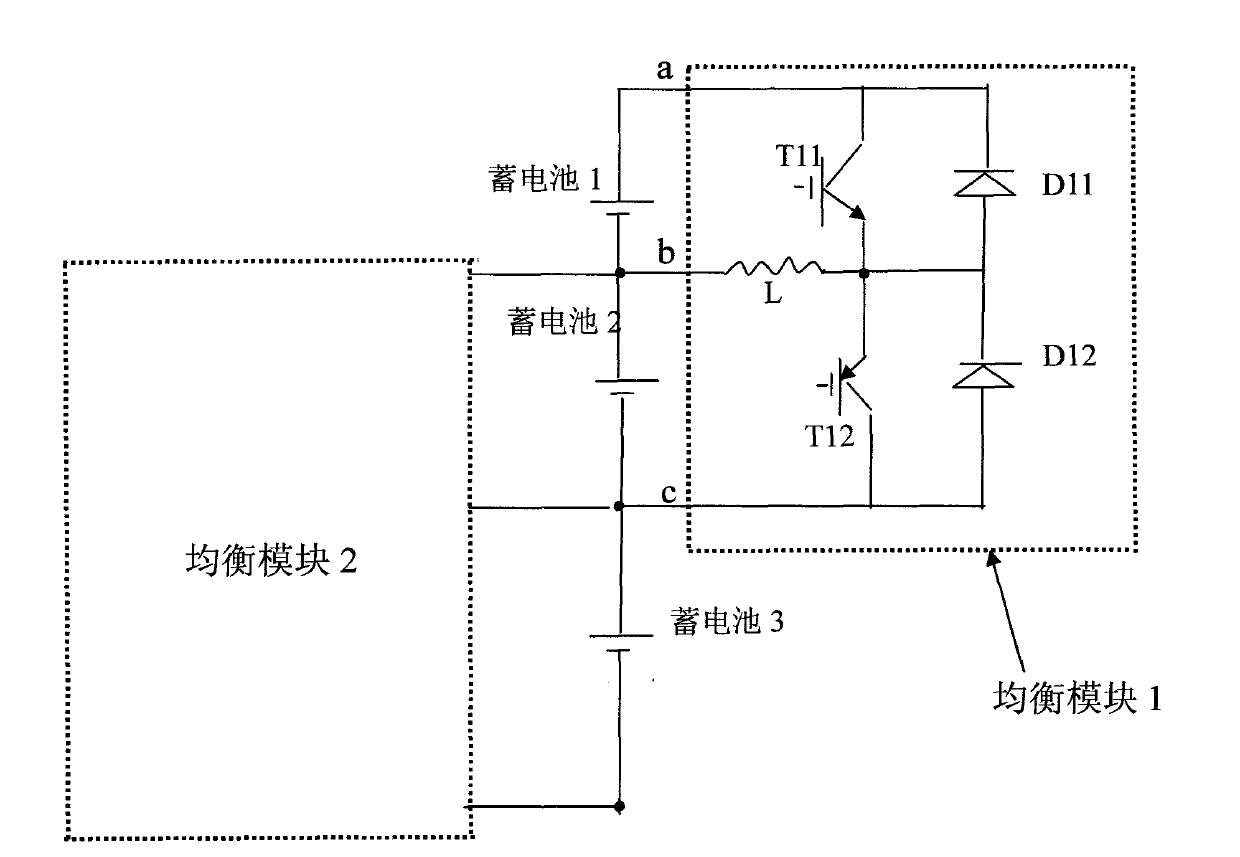

[0047] figure 1 It is a schematic diagram of the management system of series battery packs (except 2V), the system includes: a set of N series battery packs, N battery repair modules and n-1 battery balancing modules. Each battery is connected to a battery repair module in parallel, and N batteries correspond to N battery repair modules. Two batteries are connected to one equalization module, and N batteries have N-1 equalization modules.

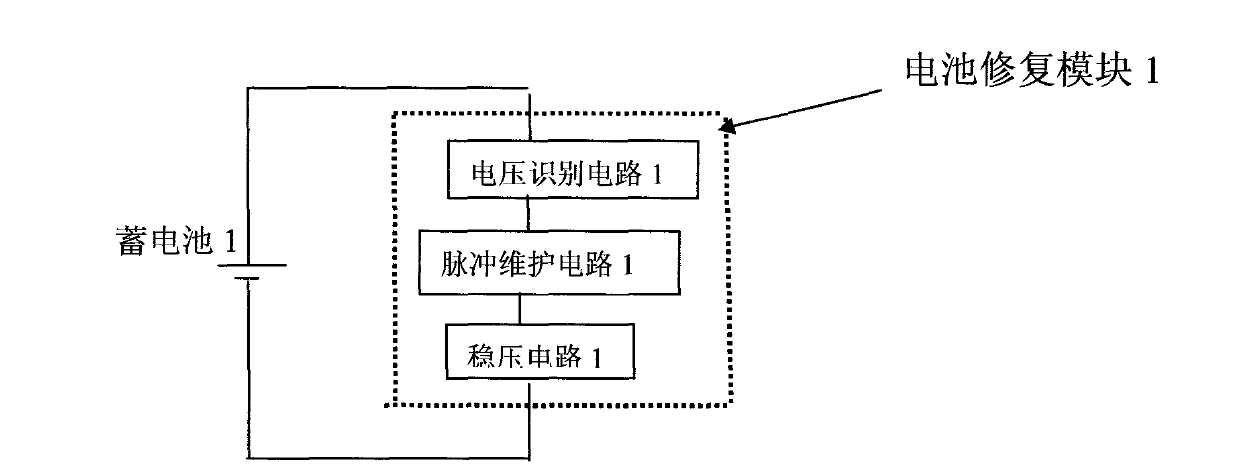

[0048] figure 2 It is a single battery and its corresponding battery repair module: the series battery pack is composed of N batteries connected in series, and each single battery is connected to a battery repair module. Each battery repair module is composed of a voltage identification circuit, a pulse maintenance circuit and a voltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com