Moxifloxacin hydrochloride pharmaceutical composition and its preparation method

A technology of moxifloxacin hydrochloride and composition, applied in the preparation of the pharmaceutical composition, the field of pharmaceutical compositions containing moxifloxacin hydrochloride, mannitol and other excipients, can solve the problem of unstable product quality, batch It can reduce the operating time and labor, and achieve the effect of good compressibility and good fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

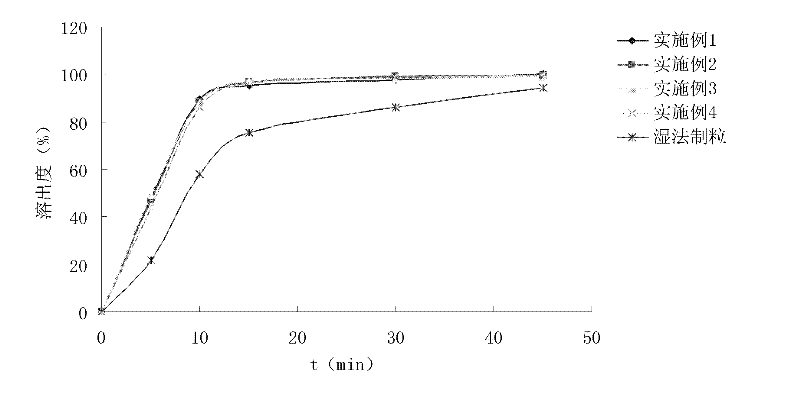

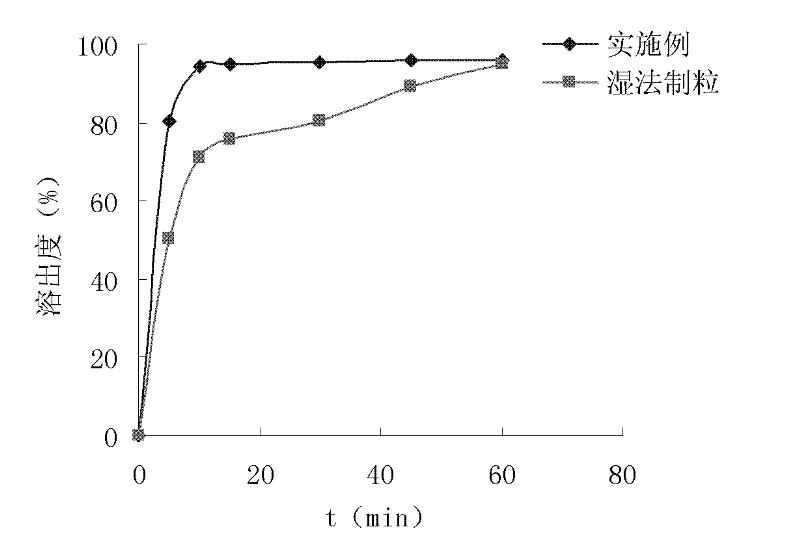

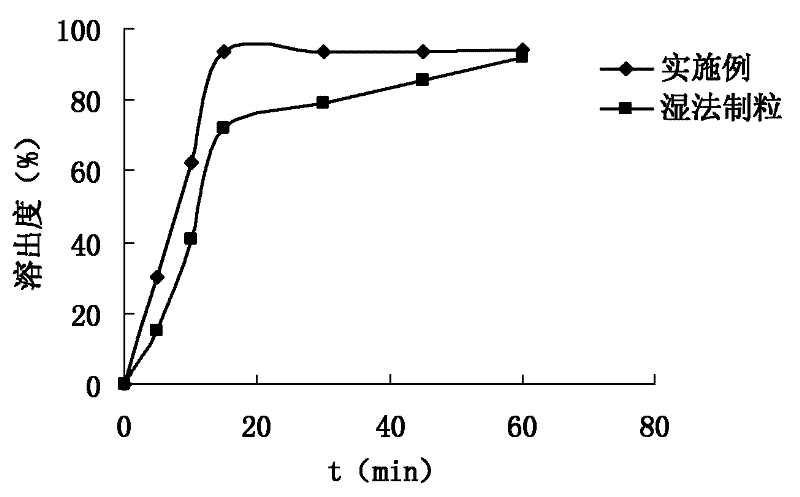

Embodiment 1

[0042] Take by weighing 500 parts by weight of moxifloxacin hydrochloride, 30 parts by weight of mannitol, 36 parts by weight of croscarmellose sodium, 180 parts by weight of microcrystalline cellulose and 4 parts by weight of magnesium stearate, press with oval Large pieces, the tablets are broken, passed through a 16-mesh sieve, and made into dry granules, and the prepared granules are added to the remaining 4 parts by weight of magnesium stearate to mix, compressed into tablets, and then used Film coated.

Embodiment 2

[0044] Take by weighing 500 parts by weight of moxifloxacin hydrochloride, 10 parts by weight of mannitol, 50 parts by weight of sodium starch glycolate, 100 parts by weight of lactose and 5 parts by weight of talcum powder, press large tablets with oval punching, and tablet is broken into pieces, Pass through a 16-mesh sieve to make dry granules, add the prepared granules to the remaining 5 parts by weight of talcum powder and mix, compress into tablets, and use Film coated.

Embodiment 3

[0046]Take by weighing 500 parts by weight of moxifloxacin hydrochloride, 50 parts by weight of mannitol, 10 parts by weight of polyvinylpolypyrrolidone, 150 parts by weight of starch and 1 part by weight of micropowdered silica gel, press large tablets with oval punching, and smash the tablets, Pass through a 16-mesh sieve to make dry granules, add the prepared granules to the remaining 1 weight part of micropowder silica gel and mix, press into tablets, and then use Film coated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com