Hybrid drive arrangement

A drive transmission system, a hybrid technology, applied in hybrid vehicles, mechanical drive clutches, fluid drive clutches, etc., can solve the problems of increasing construction space requirements, loss of power clutch heating, etc., and achieve short construction length and weight reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

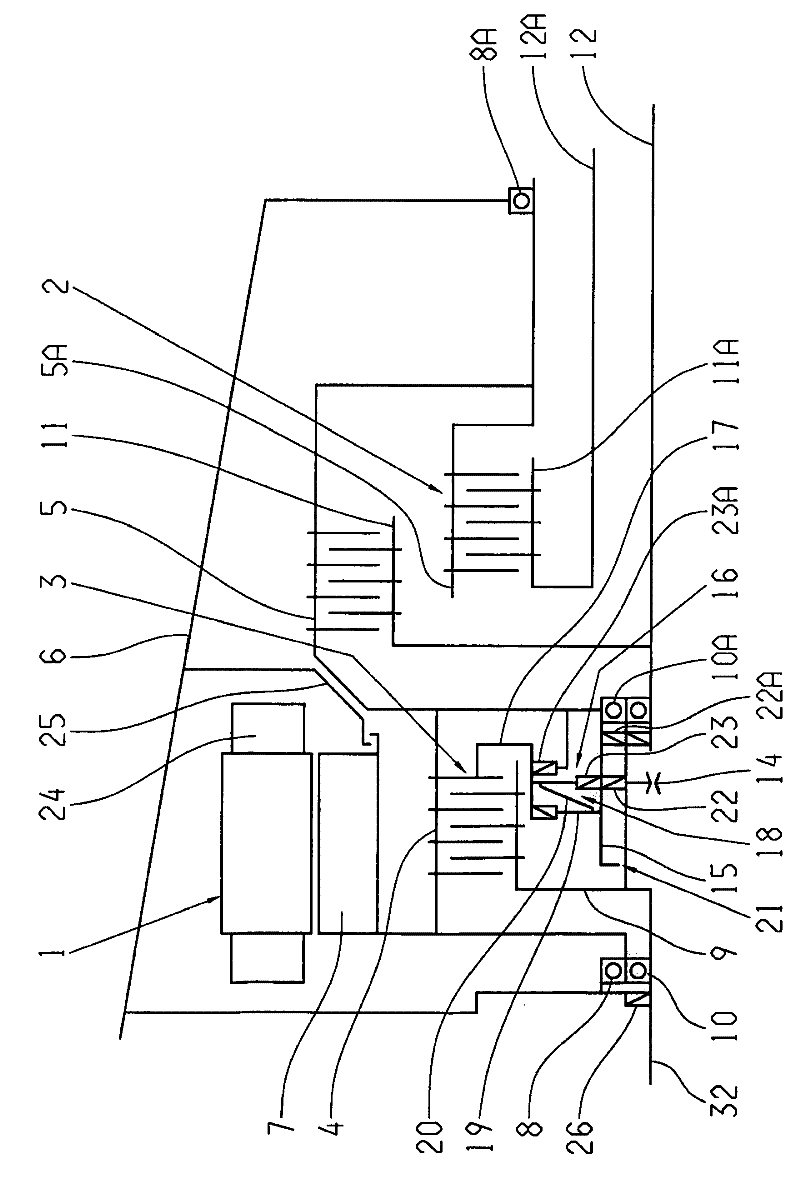

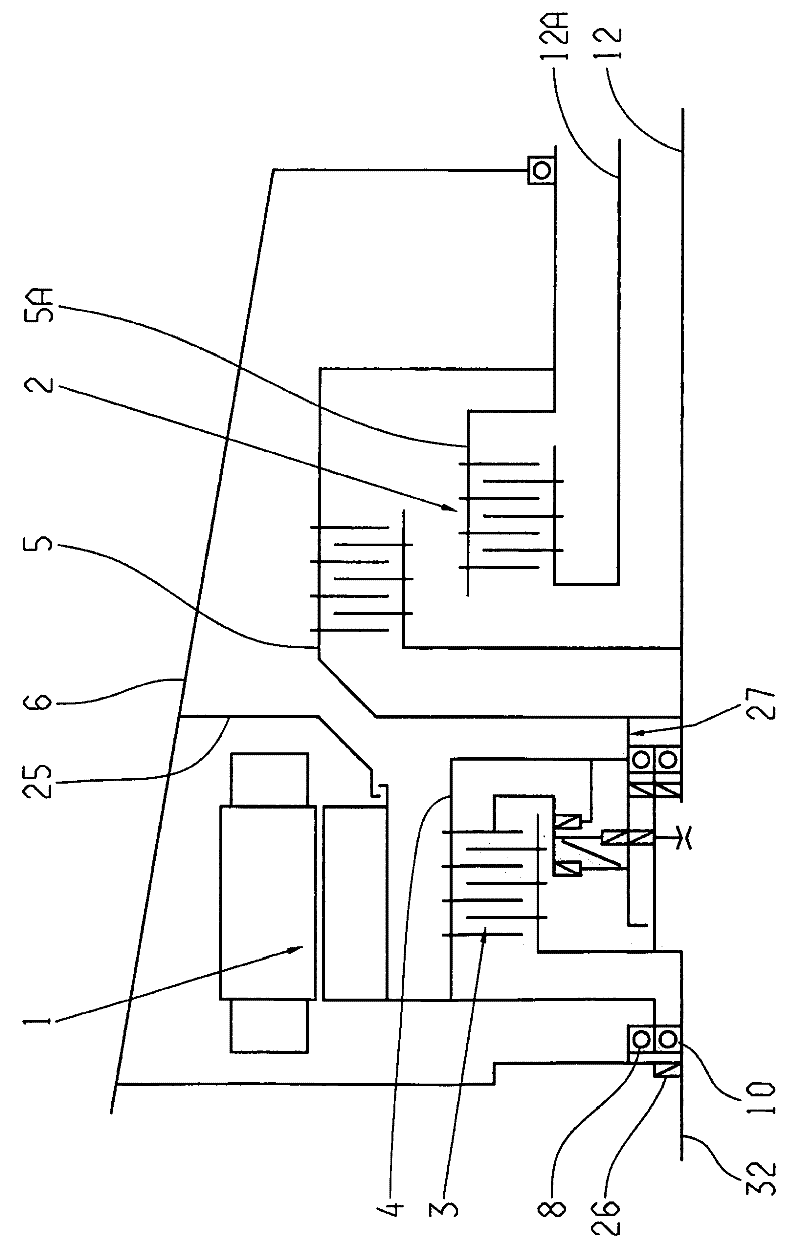

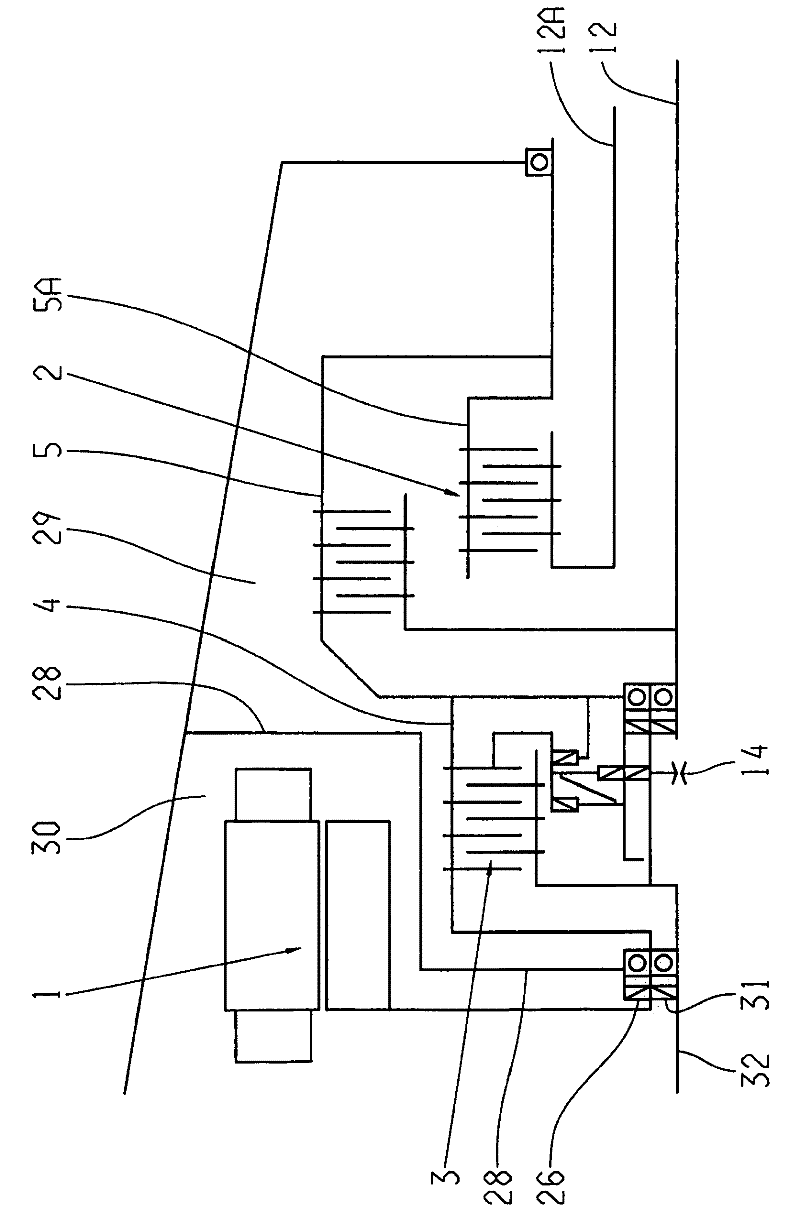

[0026] A number of different embodiment variants of a hybrid drive train for a vehicle according to the invention are shown in the drawings. Regardless of the respective embodiment variant, the hybrid drive train contains an internal combustion engine for internal combustion engine driving and at least one electric machine 1 for electric driving as well as a dual clutch transmission with dual clutch 2 . The electric machine 1 can be disconnected from the internal combustion engine via a separating clutch 3 , which is designed as a wet-running, hydraulically actuated plate clutch.

[0027] According to the invention it is provided that the outer disc carrier 4 of the separating clutch 3 is connected to the outer disc carrier 5 , 5A of the dual clutch 2 of the dual clutch transmission, which is designed as a disc clutch, and is jointly mounted on the transmission housing 6 . In this way, the combination of the split clutch and the outer disc carrier of the dual clutch is realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com