Water stemming of discharge hole of quartz crucible material-preparation furnace

A technology of water plug and quartz, which is applied in the field of raw material preparation of environmental protection optical glass and lanthanide optical glass, can solve the problems of increasing production cost, damaging the quartz crucible 3, and affecting production efficiency, so as to save production cost, meet production needs, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

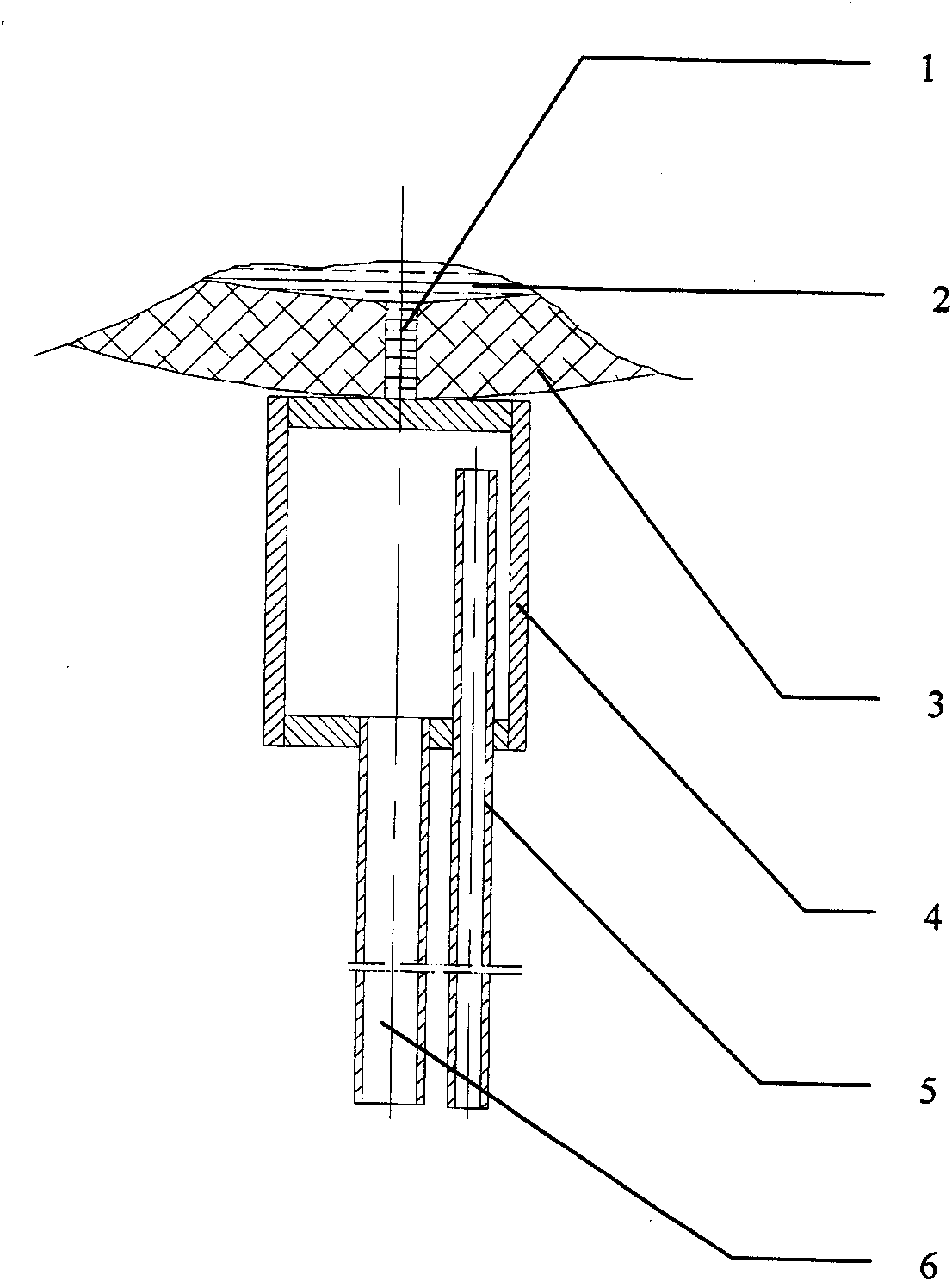

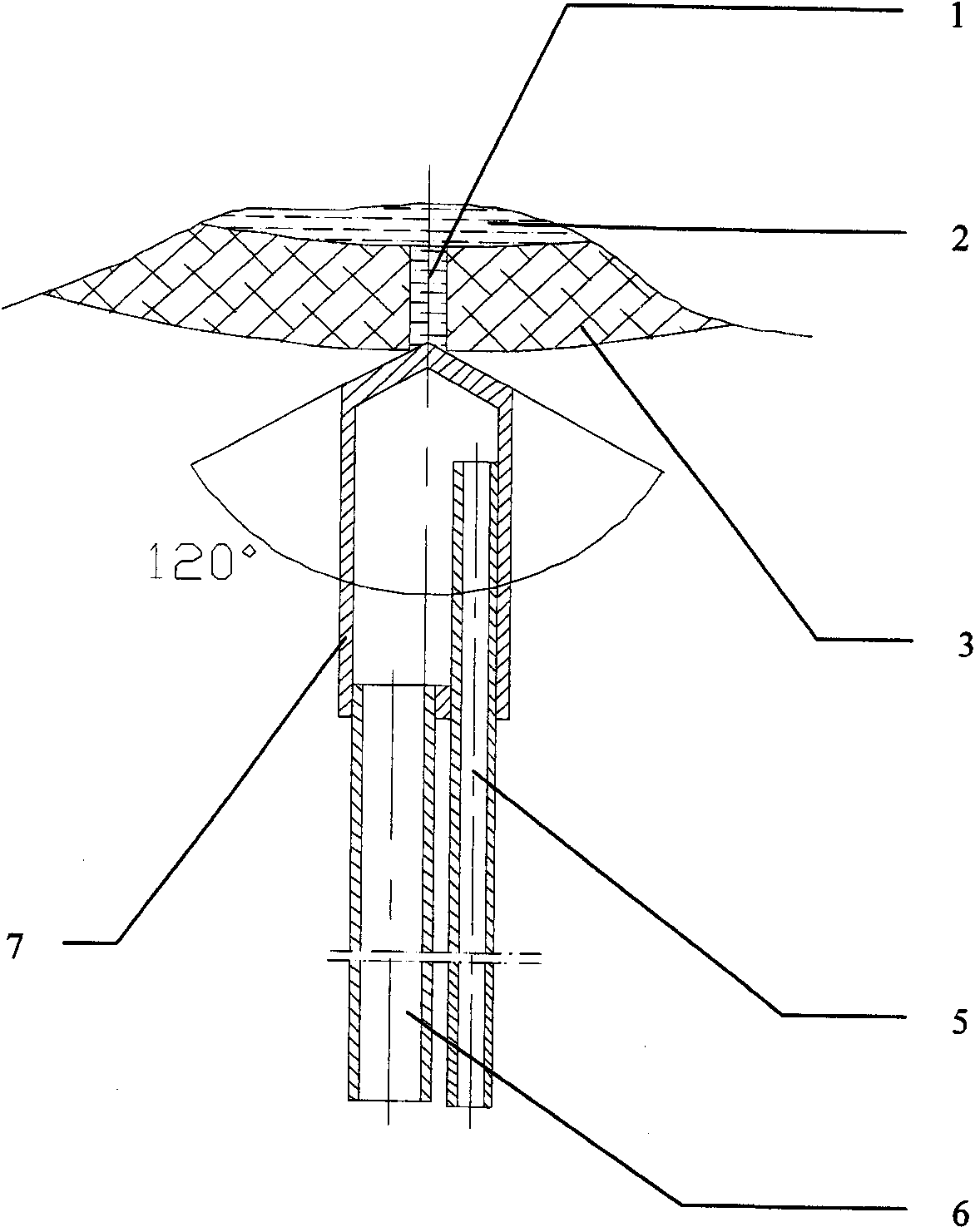

[0013] Such as figure 2 Shown. The present invention is installed on the water plug support, through the upward elastic pressing force of the spring, the cone surface of the water plug body 7 is close to the leakage opening 1 of the quartz pot 3, and the cone surface of the water plug body 7 has an automatic centering function. It not only meets the work needs, but also ensures the consistency of the quartz pot temperature. When the quartz preparation furnace is working, the water plug blocks the leaking port, the raw materials are melted into glass liquid 2 at high temperature, and the water plug circulates in the cooling water through the water inlet pipe 6 and the water outlet pipe 5 to cool the water plug, thereby protecting the water plug The role of. The water plug body 7 is a heat-resistant stainless steel product with a diameter of about φ40mm, an axial hollow (wall thickness not less than 3.5mm), and closed ends. The lower end of the water plug body 7 is provided w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com