Preparation method for reinforcing mullite by using three-dimensional carbon fiber fabric

A three-dimensional carbon fiber and fabric reinforcement technology is applied in the field of preparation of carbon fiber fabric reinforced mullite ceramics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

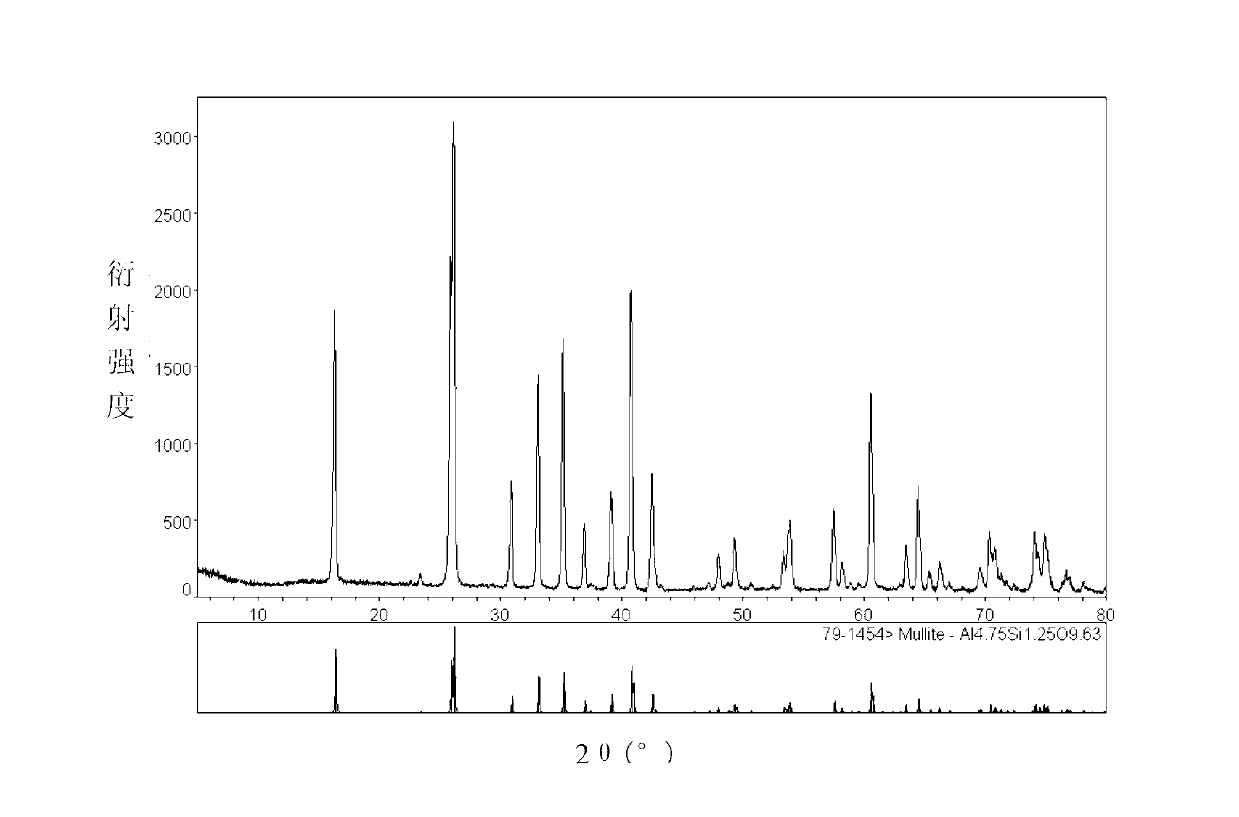

Image

Examples

Embodiment 1

[0021] A method for preparing three-dimensional carbon fiber fabric reinforced mullite ceramics of the present invention comprises the following specific steps:

[0022] (1) Preparation of mullite sol with high solid phase content: Mix silica sol with a solid phase content of 40% and aluminum sol with a solid phase content of 35% at a mass ratio of 1:3, and let it stand for 12 hours. Obtaining a stable solid phase content is 36.25% mullite sol;

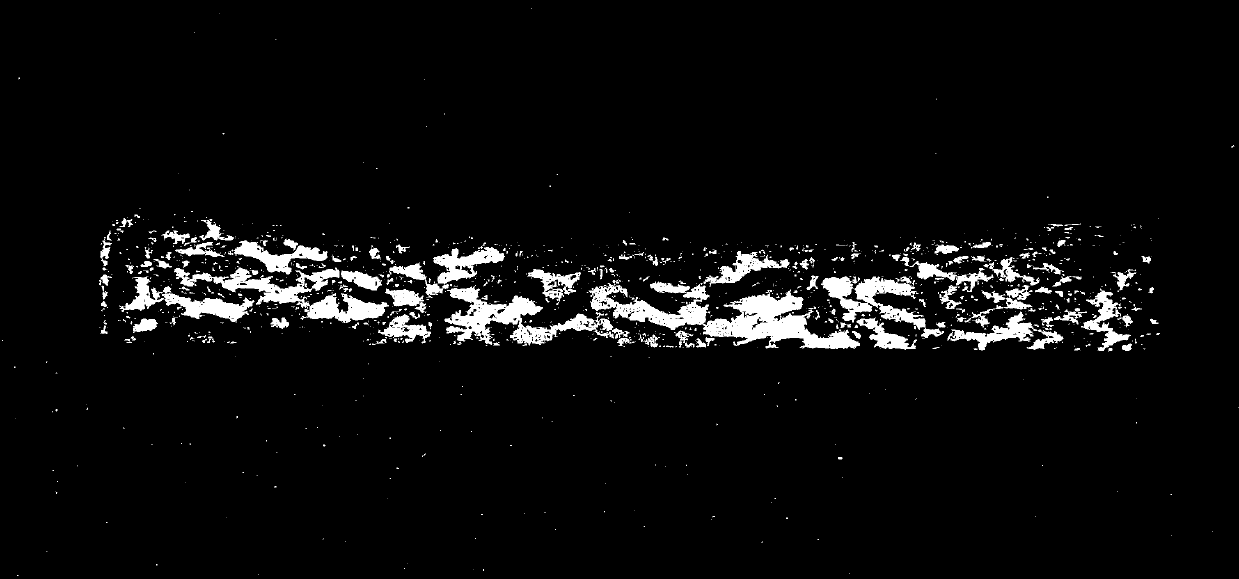

[0023] (2) Select the reinforcement: select the three-dimensional four-way carbon fiber fabric with a volume percentage of 50.5% as the reinforcement;

[0024] (3) Primary densification: use the mullite sol obtained in step (1) as a precursor, introduce it into the three-dimensional carbon fiber fabric, vacuum impregnate it for 4 hours, take it out and let it dry in the air for 2 hours; then the three-dimensional carbon fiber fabric after vacuum impregnation Put the carbon fiber fabric in a vacuum oven, heat up to 150°C at a heating ...

Embodiment 2

[0030] A method for preparing three-dimensional carbon fiber fabric reinforced mullite ceramics of the present invention comprises the following specific steps:

[0031] (1) Preparation of mullite sol with high solid content: Mix silica sol with a solid content of 35% and aluminum sol with a solid content of 30% at a mass ratio of 1:3.5, and let it stand for 24 hours. Obtaining stable solid content is the mullite sol of 31.1%;

[0032] (2) Select the reinforcement: select the three-dimensional four-way carbon fiber fabric with a volume percentage of 55% as the reinforcement;

[0033] (3) Primary densification: use the mullite sol obtained in step (1) as a precursor, introduce it into the three-dimensional carbon fiber fabric, vacuum impregnate it for 8 hours, take it out and let it dry in the air for one hour; then the three-dimensional carbon fiber fabric after vacuum impregnation Put the carbon fiber fabric in a vacuum oven, raise the temperature to 200°C at a heating rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com