Boundary phase-containing three-dimensional aluminum oxide fiber fabric-reinforced aluminosilicate ceramic and preparation method thereof

A technology of alumina fiber and aluminosilicate, which is applied in the field of oxide fiber fabric reinforced oxide ceramic materials, can solve the problems of complex preparation process of interface coating, insignificant modification effect, and limitation of practical application, etc., and achieve toughness and Increased strength, excellent chemical corrosion resistance, reduced energy consumption and the effects of equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

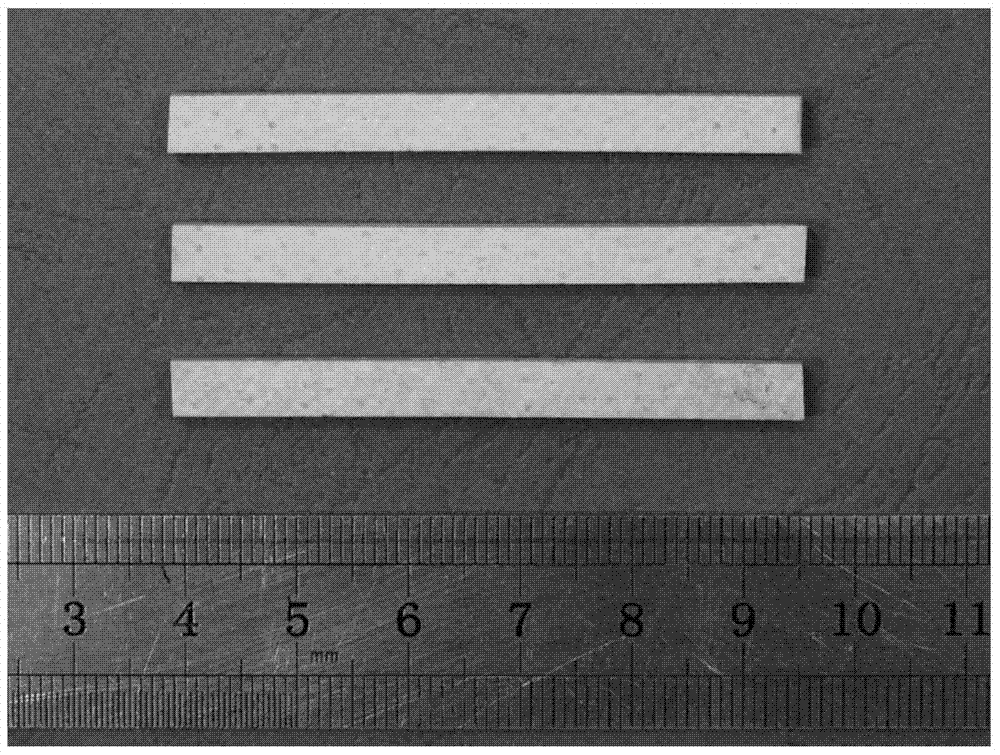

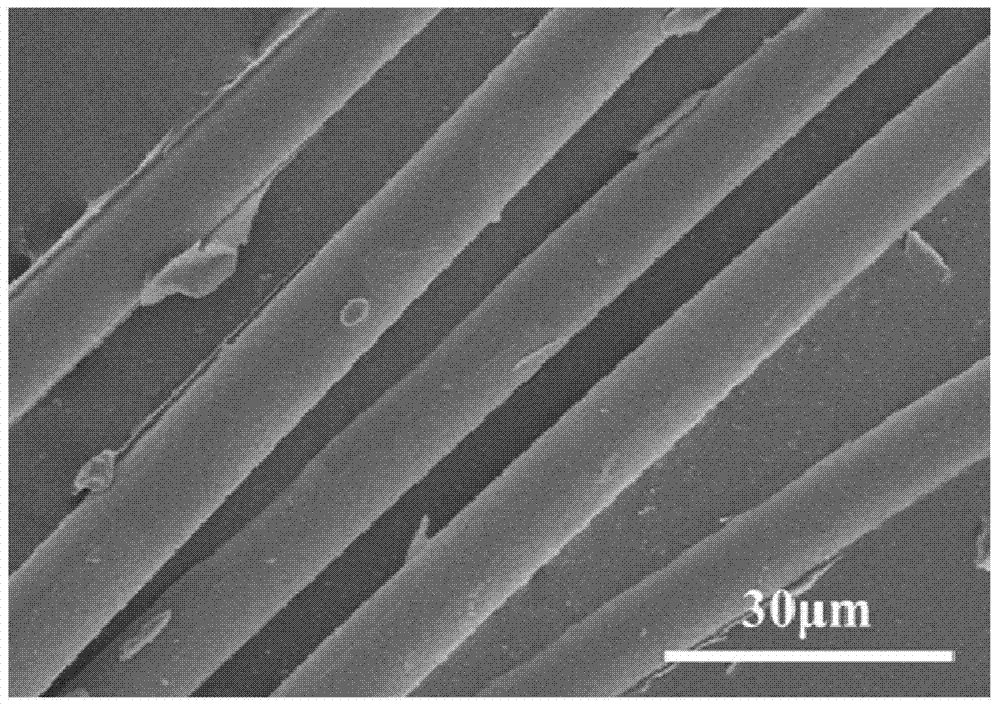

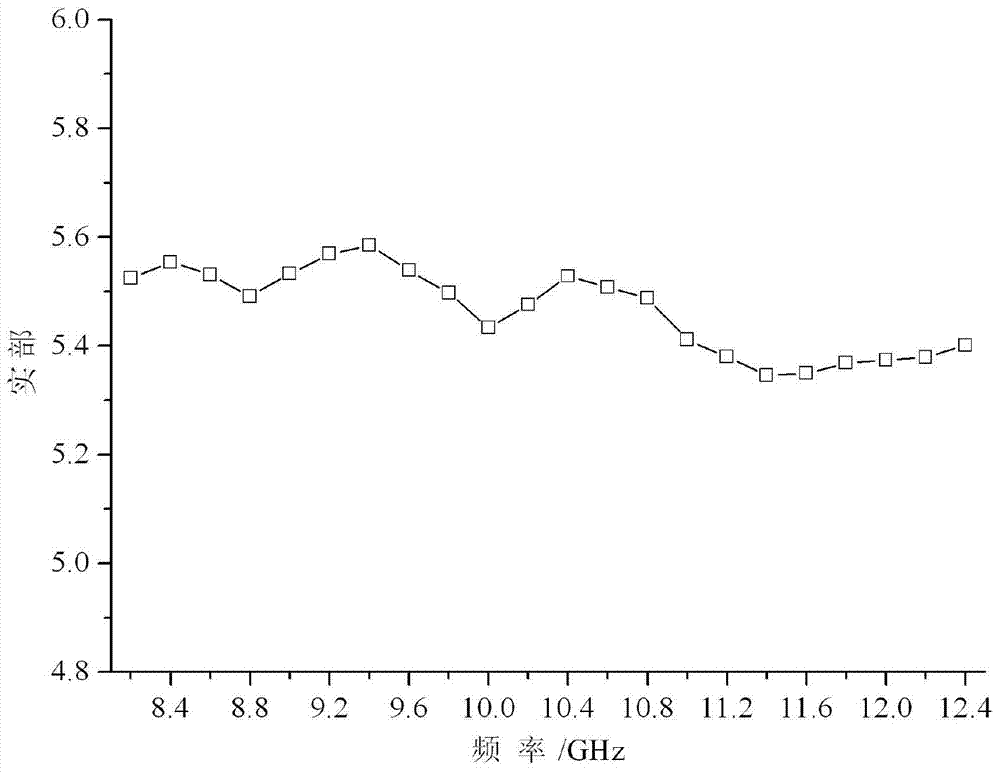

[0027] a kind of like figure 1 The three-dimensional alumina fiber fabric-reinforced aluminosilicate ceramics containing the interface phase of the present invention is shown, which uses aluminosilicate as a matrix and a three-dimensional alumina fiber fabric with a volume fraction of 42.3% as a reinforcement, and aluminosilicate A boron nitride interface phase is formed between the salt matrix and the three-dimensional alumina fiber fabric reinforcement, and the boron nitride interface phase is formed by preparing a boron nitride coating on the surface of the three-dimensional alumina fiber fabric. In this ceramic, the aluminosilicate as the matrix is made of Al with a solid phase content of 28.5%. 2 o 3 -SiO 2 A biphasic sol was prepared.

[0028] A method for preparing the above-mentioned three-dimensional alumina fiber fabric reinforced aluminosilicate ceramics, comprising the following specific steps:

[0029] (1) Preparation of boron nitride coating: prepare a thre...

Embodiment 2

[0038] A three-dimensional alumina fiber fabric reinforced aluminosilicate ceramic containing an interface phase of the present invention, which uses aluminosilicate as a matrix and a three-dimensional alumina fiber fabric with a volume fraction of 44.5% as a reinforcement, and aluminosilicate A boron nitride interface phase is formed between the salt matrix and the three-dimensional alumina fiber fabric reinforcement, and the boron nitride interface phase is formed by preparing a boron nitride coating on the surface of the three-dimensional alumina fiber fabric. In this ceramic, the aluminosilicate as the matrix is made of Al with a solid phase content of 30%. 2 o 3 -SiO 2 A biphasic sol was prepared.

[0039] A method for preparing the above-mentioned three-dimensional alumina fiber fabric reinforced aluminosilicate ceramics, comprising the following specific steps:

[0040] (1) Preparation of boron nitride coating: prepare a three-dimensional alumina fiber fabric with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com