Anti-aging electric porcelain insulator and preparation method thereof

An anti-aging and insulator technology, applied in insulators, circuits, electrical components, etc., can solve the problems of decreased insulation level, aging, affecting the performance of electric porcelain insulators, etc., and achieve the effect of reducing viscosity, improving mechanical strength, and improving mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

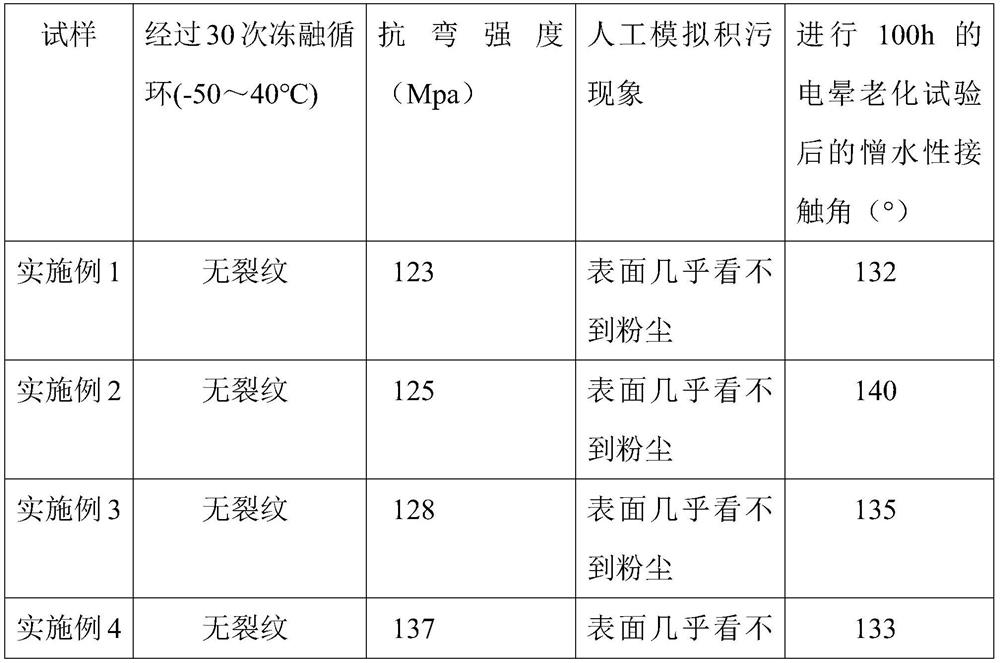

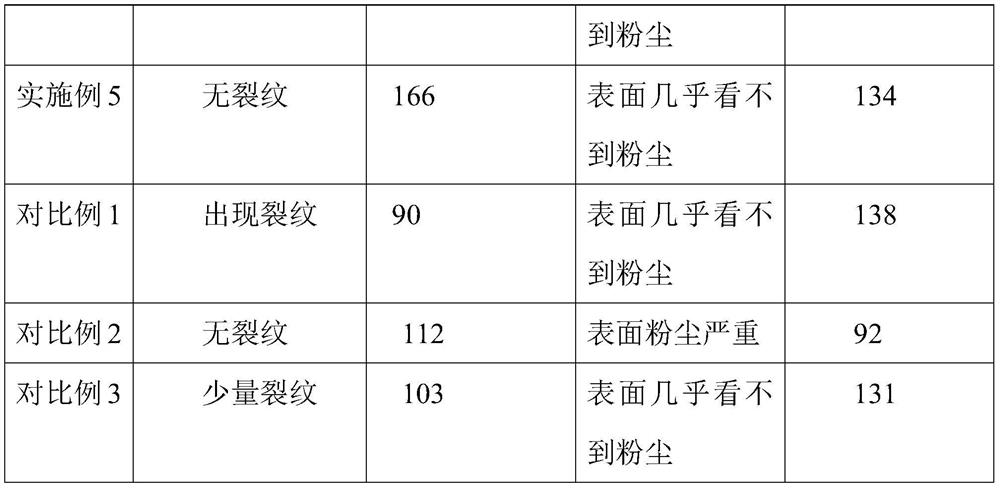

Embodiment 1

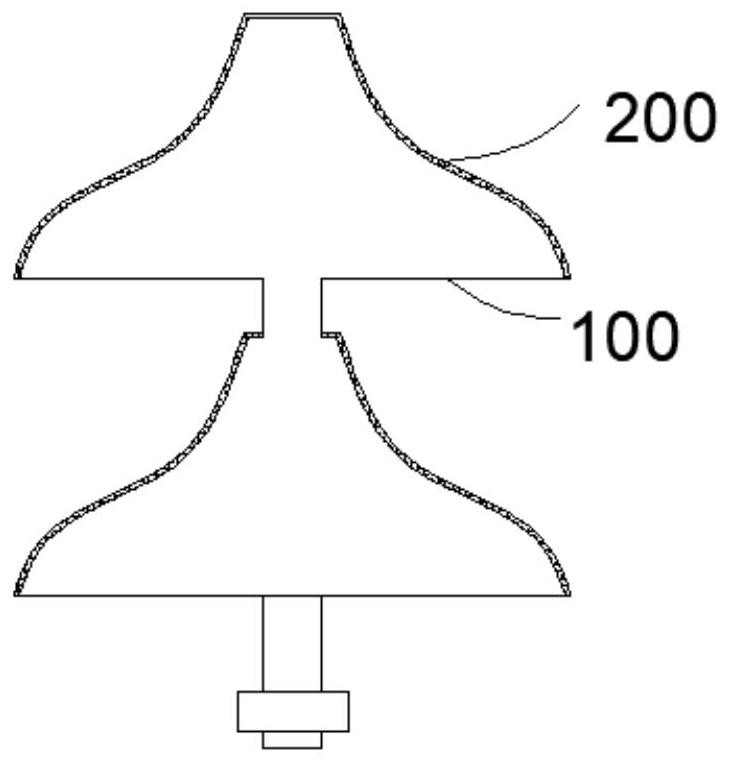

[0034] An anti-aging electric porcelain insulator, comprising a porcelain body base 100 and an anti-aging coating 200 located on the porcelain body base 100;

[0035] The preparation method is as follows: Grind the silicone resin and pass through a 60-mesh sieve to obtain silicone resin powder; weigh 100 parts of the silicone resin powder, add 23 parts of PDMS and 500 parts of acetone solution, put it into a steel mold, and press to form it. Obtain the green body; dry the green body at 60°C, raise the temperature to 200°C for 3 hours to crosslink, and solidify to obtain the green body; carry out the first stage temperature pyrolysis of the green body at 220-700°C under the protective atmosphere of inert gas, The heating rate is 2°C / min, keep at 700°C for 10 minutes, carry out the second stage temperature pyrolysis at 700-1100°C, heat up at 6°C / min, keep at 1100°C for 5 minutes, and carry out the third stage at ≥1200°C Stage temperature pyrolysis, the heating rate is 4°C / min, h...

Embodiment 2

[0037] An anti-aging electric porcelain insulator, comprising a porcelain body base 100 and an anti-aging coating 200 located on the porcelain body base 100;

[0038] The preparation method is as follows: Grind the silicone resin and pass through a 60-mesh sieve to obtain silicone resin powder; weigh 100 parts of the silicone resin powder, add 23 parts of PDMS and 500 parts of acetone solution, put it into a steel mold, and press to form it. Obtain the green body; dry the green body at 70°C, raise the temperature to 250°C for 3 hours, and solidify to obtain the green body; carry out the first stage temperature pyrolysis of the green body at 220-700°C under the protective atmosphere of inert gas, The heating rate is 2°C / min, keep at 700°C for 10 minutes, carry out the second stage temperature pyrolysis at 700-1100°C, the heating rate is 6°C / min, keep at 1100°C for 10 minutes, and carry out the third stage at ≥1200°C Stage temperature pyrolysis, the heating rate is 4°C / min, heat...

Embodiment 3

[0040] An anti-aging electric porcelain insulator, comprising a porcelain body base 100 and an anti-aging coating 200 located on the porcelain body base 100;

[0041]The preparation method is as follows: Grind the silicone resin and pass through a 60-mesh sieve to obtain silicone resin powder; weigh 100 parts of the silicone resin powder, add 23 parts of PDMS and 500 parts of acetone solution, put it into a steel mold, and press to form it. Obtain the green body; dry the green body at 70°C, raise the temperature to 200-250°C for crosslinking for 3 hours, and solidify to obtain the green body; carry out the first stage temperature heating of the green body at 220-700°C under the protective atmosphere of inert gas Solution, the heating rate is 2°C / min, keep at 700°C for 10 minutes, carry out the second stage temperature pyrolysis at 700-1100°C, the heating rate is 6°C / min, keep at 1100°C for 5 minutes, and carry out at ≥1200°C In the third stage, temperature pyrolysis, the heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com