Preparation method of ultrafiltration device

A technology of ultra-fine filtration and devices, applied in membrane filters, chemical instruments and methods, filtration and separation, etc., can solve the problems of poor wear resistance, high cost, poor chemical stability, etc., and achieve simple process, low cost, and easy industrialization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

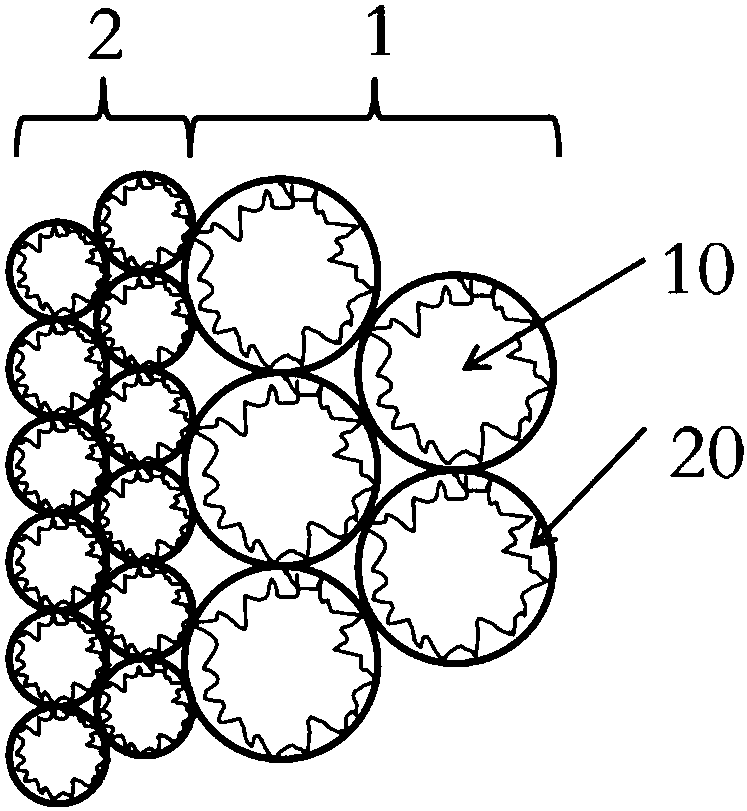

[0031] Using LY12 aluminum alloy: powder P1 with an average particle size of 500nm, and powder P2 with an average particle size of 150nm, the above aluminum alloys were mixed with PEG and stearic acid in a mass ratio of 98.4:0.6:1 to obtain P1 composite powder and P2 composite powder.

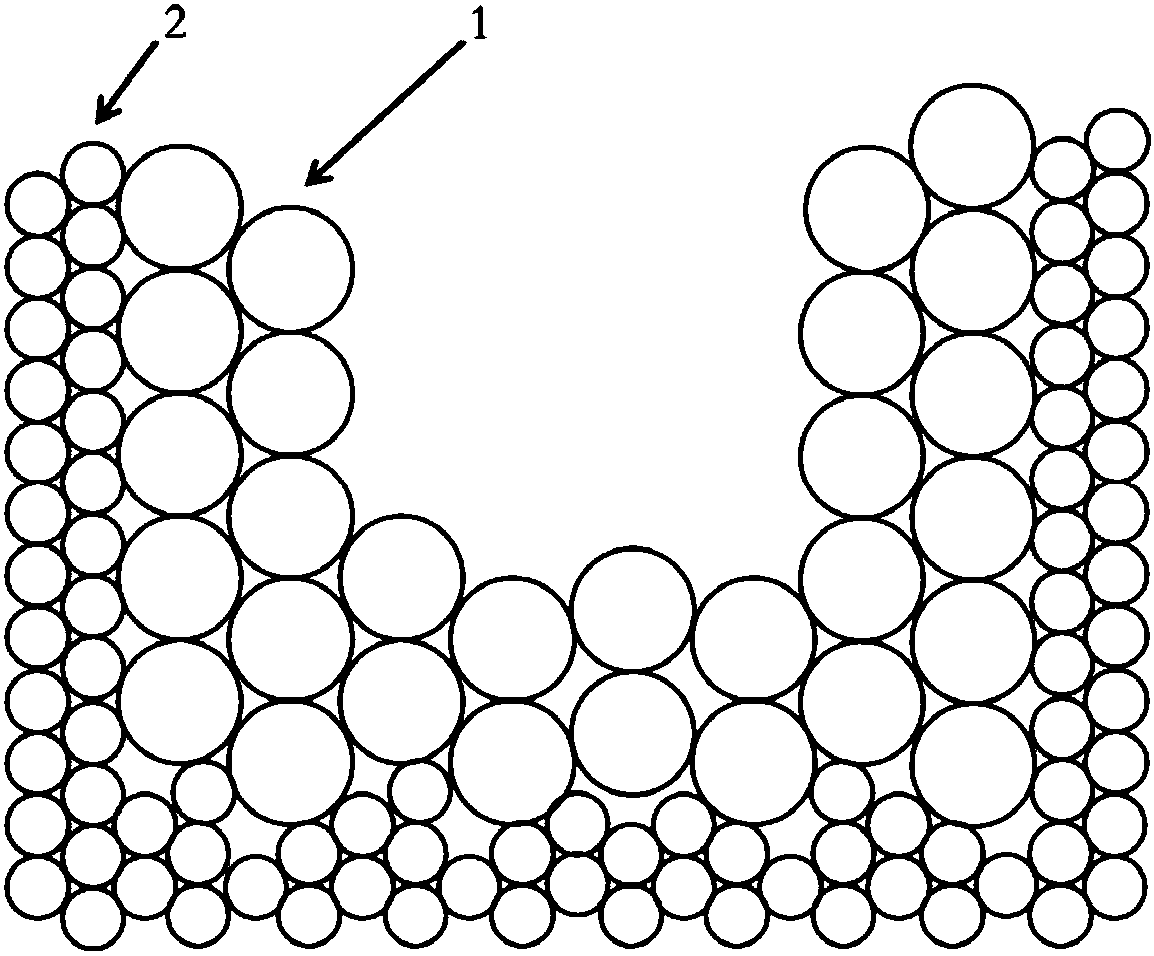

[0032] The secondary molding is formed to obtain a porous aluminum alloy product with an inner diameter of 100 mm, an inner layer composed of P1 composite powder and a thickness of 5 mm; an outer layer composed of P2 composite powder and a thickness of 20 μm, such as figure 1 shown.

[0033] The above-mentioned porous aluminum alloy filter tube is degreased, and then the boric acid solution of sodium sulfite and potassium hydroxide is used as the electrolyte, and the above-mentioned aluminum alloy filter tube is completely immersed in the electrolyte as the positive electrode, and metal lead is immersed in the electrolyte as the negative electrode. 60A / dm2, energized time 20min, uniformly form...

Embodiment 2

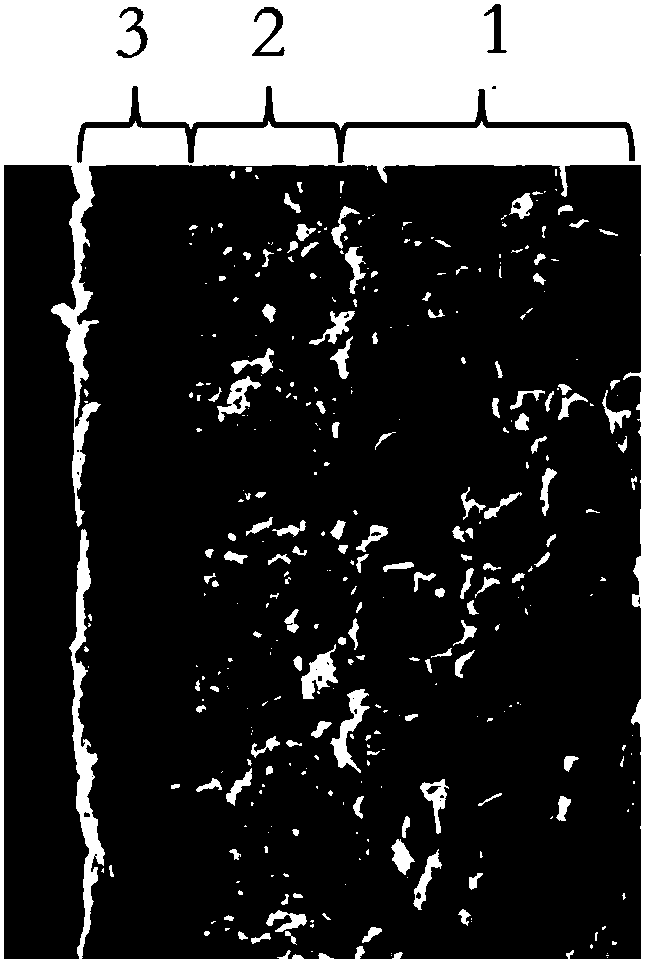

[0036] Weigh the raw materials according to the ratio of alumina powder to ammonium bicarbonate is 80:20, wherein the alumina powder is spherical with an average particle size of 60nm, and the average particle size of ammonium bicarbonate is 15nm. The alumina powder and the ammonium bicarbonate powder are ball-milled in an argon atmosphere to obtain a composite powder in which the alumina powder and the ammonium bicarbonate powder are evenly dispersed. Then, under the protection of argon, adopt the plasma spraying technology, the above-mentioned composite powder is repeatedly sprayed on the surface of the ultrafine filter part obtained in Example 1, then stand in boiling water for 1h, after the ammonium bicarbonate dissolves and detaches, in the implementation Example 1 A uniform and compact aluminum oxide nano-ceramic filter layer (Fig. 3) was obtained on the surface of the workpiece, with a filter hole diameter of about 10 nm and a porosity of about 38%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com