Biodegradable free-spraying aesthetic resin and preparation method thereof

A kind of aesthetic resin and biodegradable technology, which is applied in the field of biodegradable spray-free aesthetic resin and its preparation, can solve the problems that it is difficult to achieve consistent fluidity, poor compatibility, and no polylactic acid resin has been found, and achieve a good metallic luster effect , excellent mechanical properties and thermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Put 40kg of L-polylactic acid resin, 25kg of core-shell impact modifier, 35kg of polymethyl methacrylate resin, 0.2kg of antioxidant IG-245, 0.2kg of antioxidant 168, and 0.7kg of lubricant EBS at 60°C Dry in oven for 5~8h;

[0040] Dilute the coupling agent (KH550) with absolute ethanol at a ratio of 1:20, then mix it with aluminum powder or pearlescent pigment at a weight ratio of 1:5, and then place it in a high-speed mixer for 3-10 minutes. Complete the surface pretreatment of aluminum powder pigments;

[0041] Add 0.5kg of the above-mentioned metallic pigments and 0.3kg of pearlescent pigments that have undergone surface pretreatment, together with all the above-mentioned dried raw materials, into a high-speed mixer and stir for 25 minutes before discharging. Then, when the aspect ratio is 36 and the diameter is Extrude and granulate in a 35mm twin-screw extruder, the barrel temperature of the extruder is 170-220°C, and the screw speed is 200-600rpm.

Embodiment 2

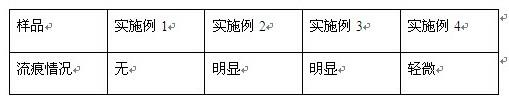

[0043] In order to reflect the significance of using modified polylactic acid in the present invention, this example is specifically compared and implemented.

[0044] Dry 100kg of L-polylactic acid resin, 0.2kg of antioxidant IG-245, 0.2kg of antioxidant 168, and 0.7kg of lubricant EBS in an oven at 60°C for 5~8h;

[0045]Dilute the coupling agent (KH560) with absolute ethanol at a ratio of 1:20, then mix it with aluminum powder or pearlescent pigment at a weight ratio of 1:5, and then place it in a high-speed mixer for 3-10 minutes. Complete the surface pretreatment of aluminum powder pigments;

[0046] Add 0.5kg of the above surface-treated metallic pigments and 0.3kg of pearlescent pigments together with all the above-mentioned dried raw materials into a high-speed mixer and stir for 25 minutes before discharging. Extrude and granulate in a twin-screw extruder, the barrel temperature of the extruder is 170~220°C, and the screw speed is 400rpm.

Embodiment 3

[0048] In order to reflect the significance of the impact modifier surface active groups on the improvement of flow marks, this example is specifically compared and implemented.

[0049] 40kg of L-polylactic acid resin, 25kg of styrene-butyl acrylate-acrylic acid copolymer, 35kg of polymethyl methacrylate resin, 0.2kg of antioxidant IG-245, 0.2kg of antioxidant 168, 0.7kg of lubricant EBS, Dry in an oven at 60°C for 5~8h;

[0050] Dilute the coupling agent (KH550 or KH560) with absolute ethanol at a ratio of 1:20, then mix it with aluminum powder or pearlescent pigment at a weight ratio of 1:5, and then place it in a high-speed mixer for 3~ 10min, complete the surface pretreatment of the aluminum powder pigment;

[0051] Add 0.5kg of the above surface-treated metallic pigments and 0.3kg of pearlescent pigments together with all the above-mentioned dried raw materials into a high-speed mixer and stir for 25 minutes before discharging. Extrude and granulate in a twin-screw ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com