Isopycnic cutting slurry for linear cutting of solar wafer and manufacturing method thereof

A technology of solar silicon wafer and wire cutting, applied in the direction of lubricating composition, etc., can solve the problems of increased cost, control and influence of mortar cutting ability of enterprises, and achieve the effect of reducing cutting cost and controlling the environment of auxiliary materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

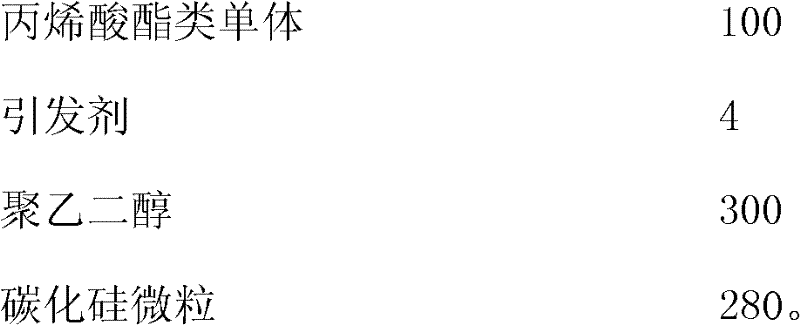

[0030] 1. The weight composition of equal density cutting mortar:

[0031]

[0032] 2. Manufacturing method of equal density cutting mortar:

[0033] a. Weigh 3 / 4 of the total amount of polyethylene glycol to dissolve N-methylolacrylamide and acrylamide, and add N-methylolacrylamide and acrylamide to the polyethylene glycol while stirring, so that its full dissolution;

[0034] b. take acrylic acid and dissolve 4 / 5 of the total amount of the initiator into it;

[0035] c. Mix the above two solutions evenly, weigh half of the total amount of the mixed solution and add it to the copolymerization device, heat and start the stirrer, and condense the reflux system. Timing, under the condition of maintaining the reflux temperature of 75 ℃ ~ 80 ℃, it takes 3.5 hours to add 1 / 2 of the silicon carbide particles with the feeding device under the condition of sufficient stirring;

[0036] d. After 3.5 hours under the condition of maintaining the reflux temperature of 75°C to 80°C, ...

Embodiment 2

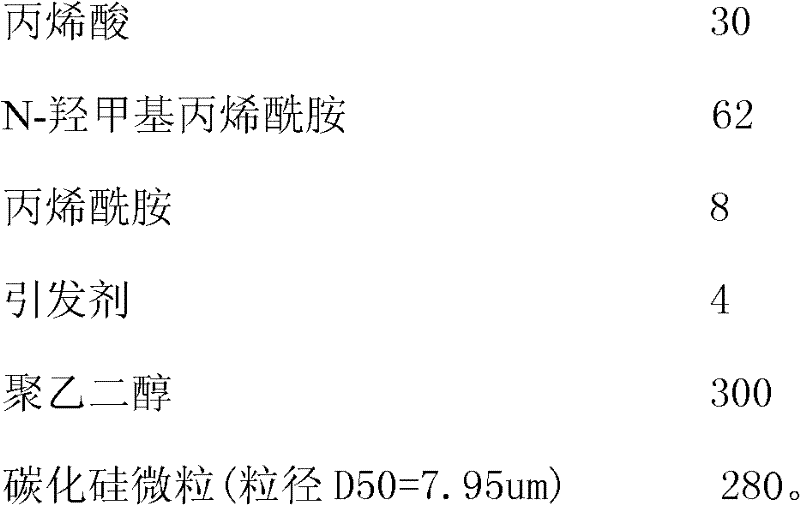

[0040] 1. The weight composition of equal density cutting mortar:

[0041]

[0042] 2. Manufacturing method of equal density cutting mortar:

[0043] a. Weigh 3 / 4 of the total amount of polyethylene glycol to dissolve N-methylolacrylamide, methyl methacrylate and butyl acrylate, the same as in Example 1 below.

Embodiment 3

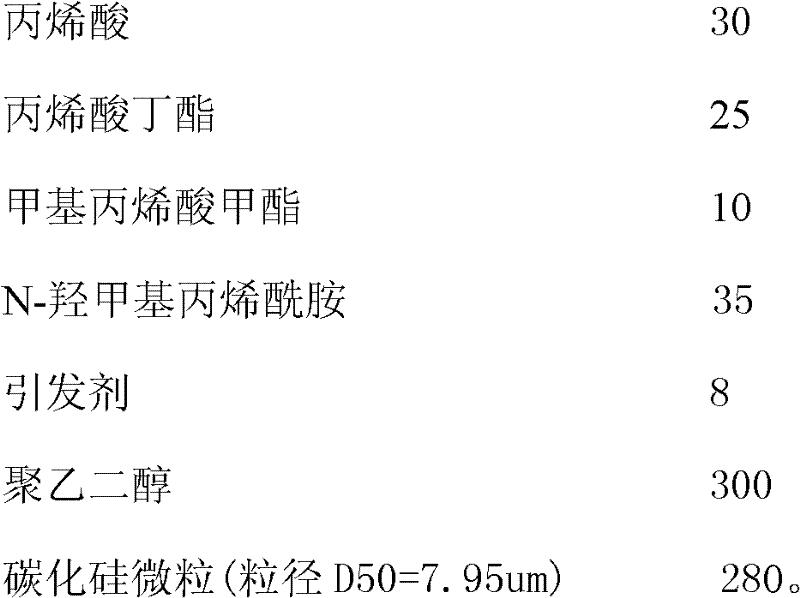

[0045] 1. The weight composition of equal density cutting mortar:

[0046]

[0047] 2. Manufacturing method of equal density cutting mortar:

[0048] a. Weigh 3 / 4 of the total amount of polyethylene glycol to dissolve N-methylolacrylamide, ethyl methacrylate and octyl acrylate, the same as in Example 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com