Casting method of core of casting mould

A casting mold and core technology, which is applied in casting molding equipment, casting molds, cores, etc., can solve the problems of high manufacturing cost, affecting the surface quality of wax molds, wax performance, and difficulty in dissolving, so as to solve the problem of wax saponification and reduce resources. The effect of enriching and reproducing and eliminating environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

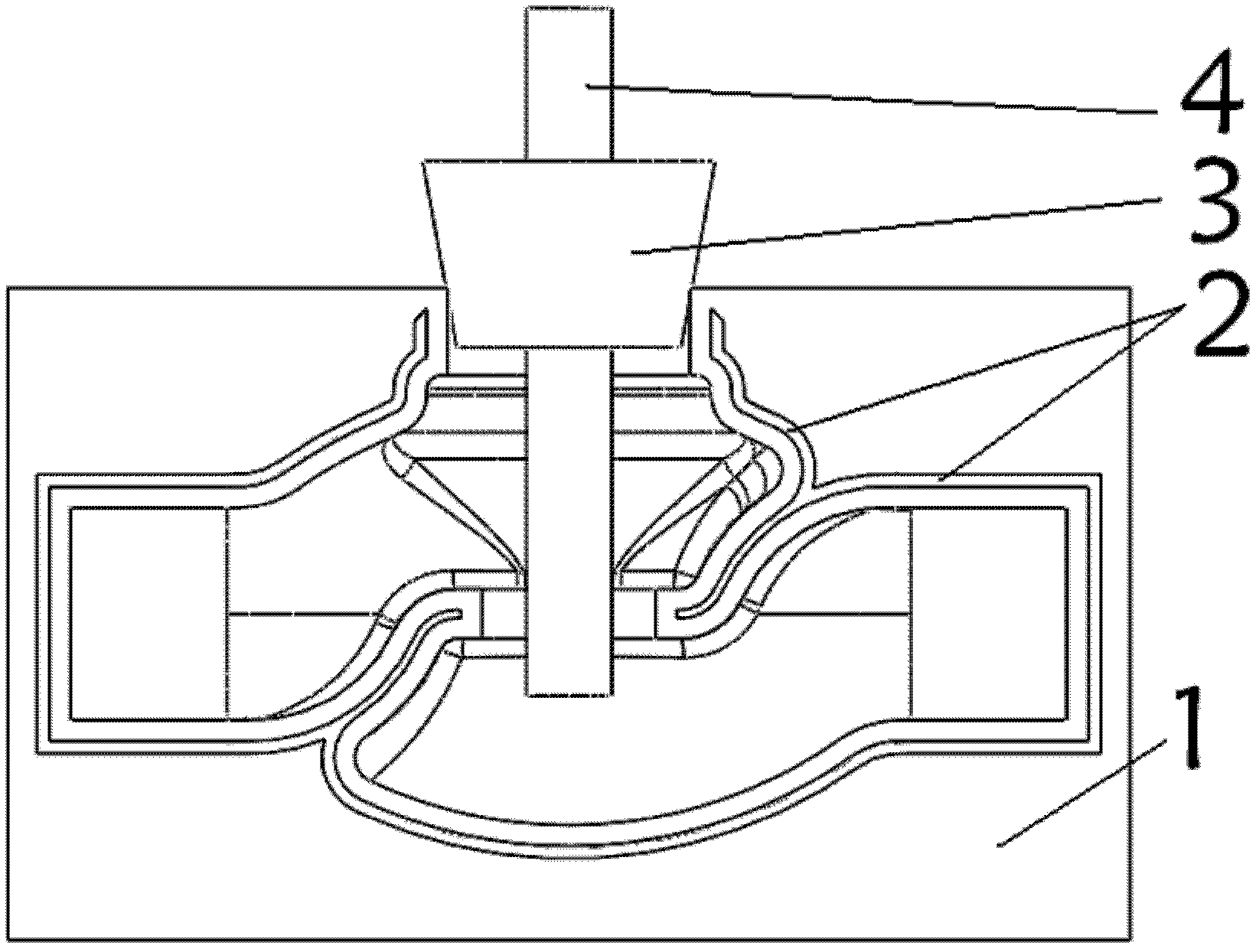

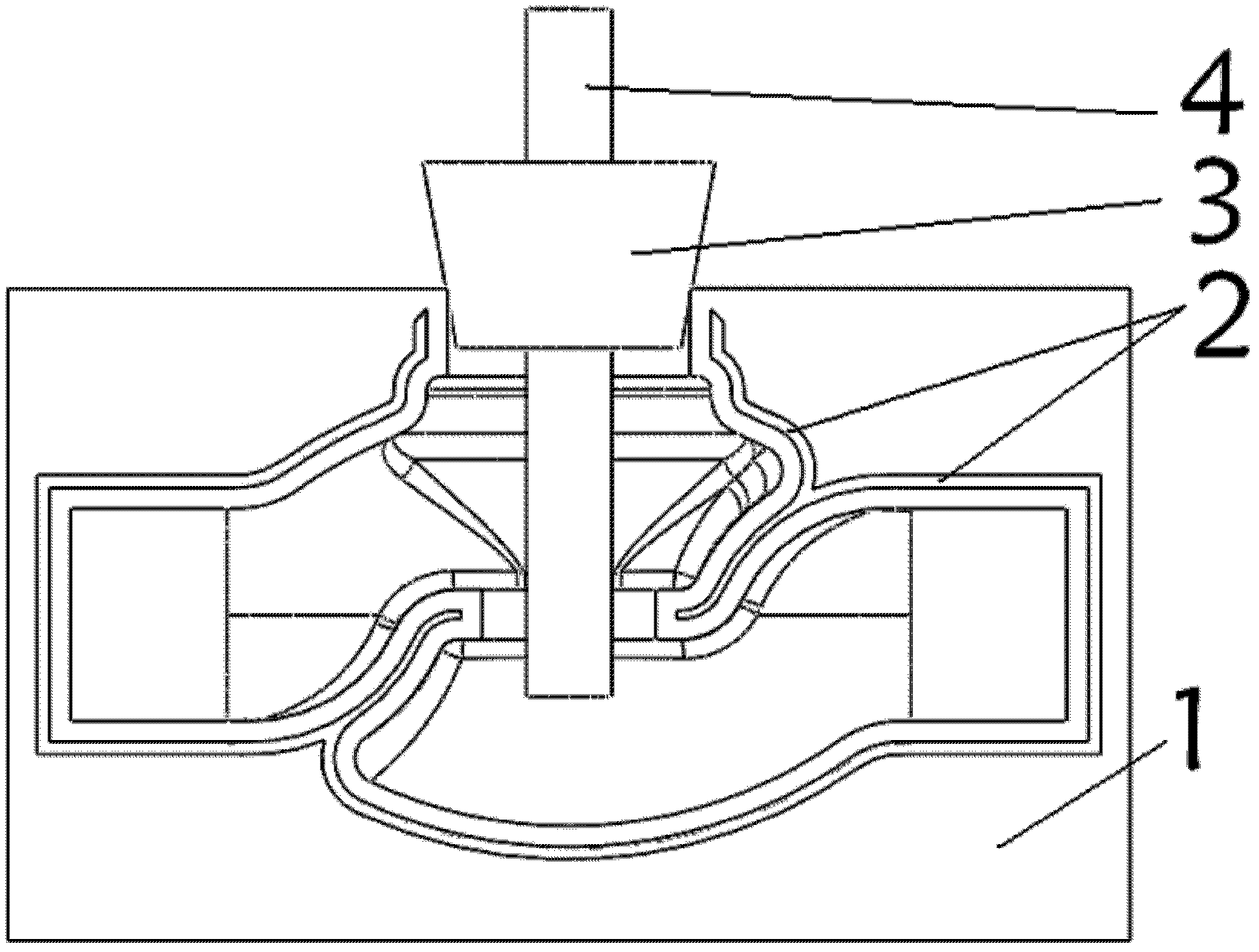

[0016] Referring to accompanying drawing, a kind of casting method of casting mold core: figure 1 It is the structure diagram of the ice core mold: core mold 1; sealing strip 2; sealing plug 3; drainage conduit 4,

[0017] (1) First, assemble and seal the mold, pour liquid (water) from the inlet, and then install a sealing plug containing a drainage conduit at the water injection port;

[0018] (2) Next, place the mold in a sealed environment with specified cooling and heat preservation effects and relatively airtight conditions; let it condense and form ice in the airtight environment;

[0019] (3) Then, take the obtained ice core out of the mold and put it in a designated environment for storage;

[0020] (4) Finally, assemble the ice core into the mold, inject wax, cool, and melt the core to obtain the wax model of the required cavity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com